Open, Closed – Enerpac ATP-Series User Manual

Page 5

5

4.4 Pump Priming (air bleeding)

IMPORTANT: New pumps MUST be primed BEFORE initial start-

up. Perform priming procedure as described in the following

steps. Refer to fi gures 4 through 7.

1. Be sure that hydraulic reservoir is fi lled with the correct oil

and that reservoir outlet valve is open. Refer to Section 4.1.

2. Be sure that the air-shutoff valve is in the CLOSED position

and that the oil return-to-tank valve is open.

3. Loosen

the

reservoir

fi ller cap about one-half turn to provide

air venting. Venting is required for proper operation.

E RELEASE VALVE

OT CLOSE WITH

DUE FORCE.

EN SLOWLY

OPEN

(pump on)

CLOSED

(pump off)

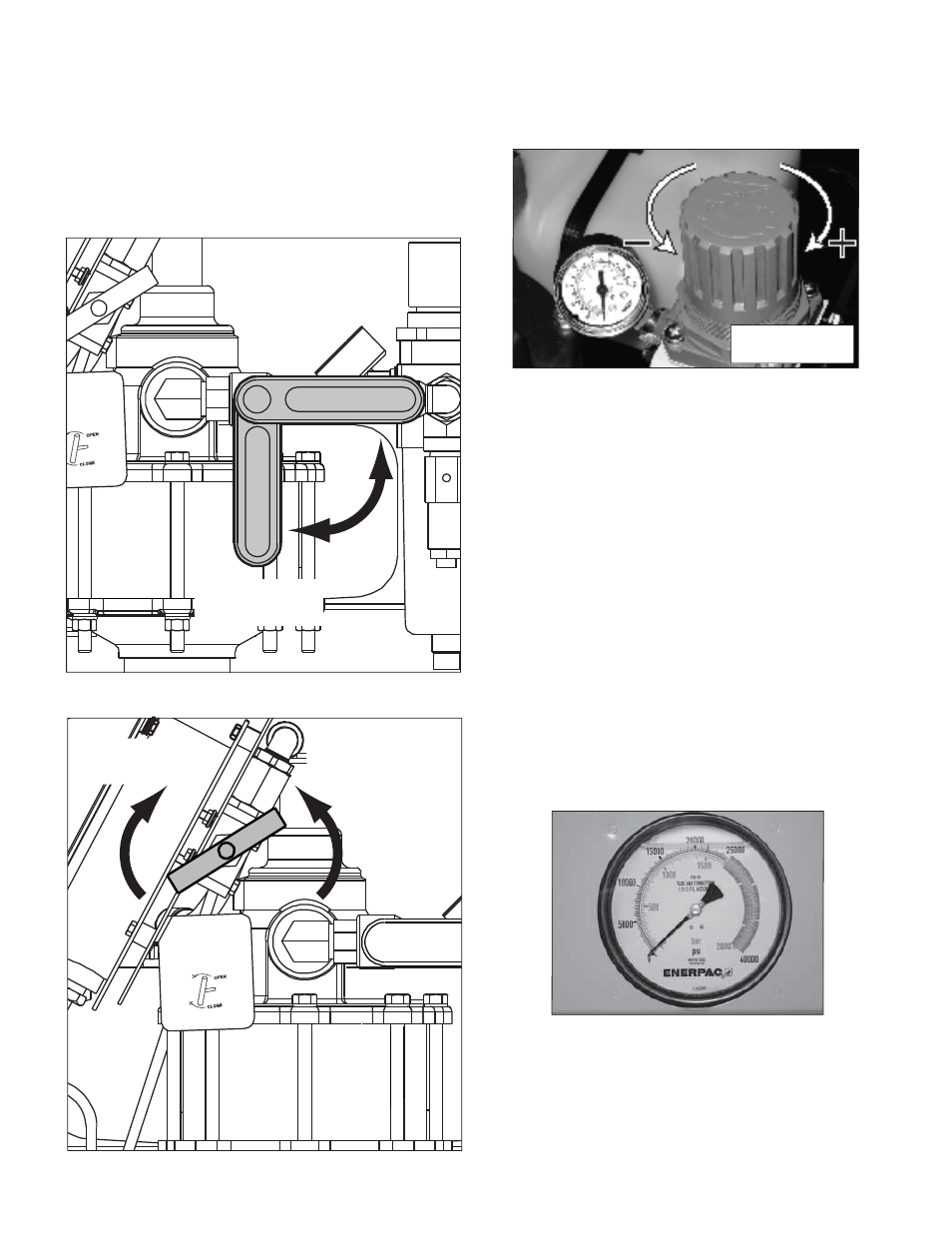

Figure 4, Air-Shutoff Valve

PRESSURE RELEASE V

ALVE

DO NOT CLOSE WITH

UNDUE FORCE.

OPEN SLOWLY

OPEN

(pressure release

to tank)

CLOSED

(oil fl ow to tool)

Figure 5, Oil Return-to-Tank Valve

4. Connect air supply hose to the pump air inlet connection.

5. While air-shutoff valve remains CLOSED, activate air

source and check the air pressure gauge. If any pressure is

indicated, turn air pressure regulator knob counter-clockwise

as required, until gauge indicates zero [0] psi/bar.

• Pull up to turn.

• Push down to lock.

Figure 6, Air Pressure Gauge and Regulator

6. Connect one end of a 3 foot [1 m] long hydraulic hose to the

pump oil outlet connection.

7. Install an open-ended quick disconnect fi tting on other end

of hose.

8. Unscrew

the

reservoir

fi ller cap. Place hose end with open-

ended fi tting inside reservoir. This will allow oil return during

priming.

9. Close the oil return-to-tank valve. Move the air-shutoff valve

to the OPEN position.

10. Using the air pressure regulator, SLOWLY increase air

pressure from 0 psi to 10-15 psi [0,68 - 1,0 bar] to start

pump operation.

11. Verify that oil is returning to the reservoir through the hose.

Increase air pressure to 40 psi [2,75 bar] until all air is purged

from the system (no bubbles visible in return oil stream).

12. Move the air-shutoff valve back to the CLOSED position.

The pump will stop.

13. Turn the air pressure regulator knob counter-clockwise until

zero [0] psi/bar is indicated on the air pressure gauge.

14. Open the oil return-to-tank valve to relieve any residual

hydraulic pressure. Verify that hydraulic pressure gauge

indicates zero [0] psi/bar.

.

Figure 7, Hydraulic Pressure Gauge

15. Remove the 3 foot [1 m] long oil return hose from the

reservoir. Reinstall the reservoir fi ller cap.

16. Disconnect the oil return hose from the pump oil outlet

connection.