Enerpac ATP-Series User Manual

Page 7

7

WARNING: Before beginning any maintenance or

repairs, be sure that oil return-to-tank valve is open and

that air-shutoff valve is closed. Always disconnect air

and hydraulic lines from pump. Verify that gauges indicate zero

[0] psi/bar.

7.1 Air Filter

Replace the air fi lter element if it appears dirty, or if there is a

noticeable drop in airfl ow. See Figure 9 for parts diagram.

7.2 Filter Bowl Drain Port

The fi lter bowl will automatically drain itself when the water level

rises to approximately 1/3 bowl height. The bowl must be

pressurized to at least 22 psi [1,5 bar] for automatic draining to

occur. If desired, a drain hose with a 1/8 inch BSPP fi tting (user-

supplied) can be connected to the bowl drain port.

Replace the entire bowl assembly if the auto-drain feature fails to

operate. See Figure 9 for parts diagram.

IMPORTANT: To prevent damage to the auto-drain assembly, do

not attempt to loosen the drain port nut. The bowl contains no

manual drain valve. If manual draining is desired, shut-off air

supply and drain any retained water by removing the bowl.

7.3 Air Muffl er

Periodically inspect the air muffl er. Remove any loose dirt or oil

residue with a rag. Replace the muffl er if it becomes clogged or

if there is a noticeable increase in pump noise. See Figure 8 for

location.

7.4 Oil Change

Enerpac HF oil is a crisp blue color. Frequently check oil condition

for contamination by comparing pump oil to new Enerpac oil. As

a general rule, completely drain and clean the reservoir every 250

hours, or more frequently if used in dirty environments.

Change the oil as described in the following steps. Refer to Figure

8:

1. Close reservoir outlet valve.

2. Disconnect

oil

hose

at

hydraulic

fi lter. Place a suitable

container under open end of hose.

3. Open the reservoir outlet valve. Allow oil to drain into the

container below. Dispose of used oil in accordance with all

applicable regulations and laws.

4. Disassemble

the

hydraulic

fi lter assembly. Clean and reinstall

(or replace) the hydraulic fi lter element. Refer to Section 7.5

for additional information.

5. Reattach

oil

hose

to

hydraulic

fi lter. To prevent air entry or

leaks, be sure connections are tight.

6. Open reservoir outlet valve. Prime the pump as described in

Section 4.4.

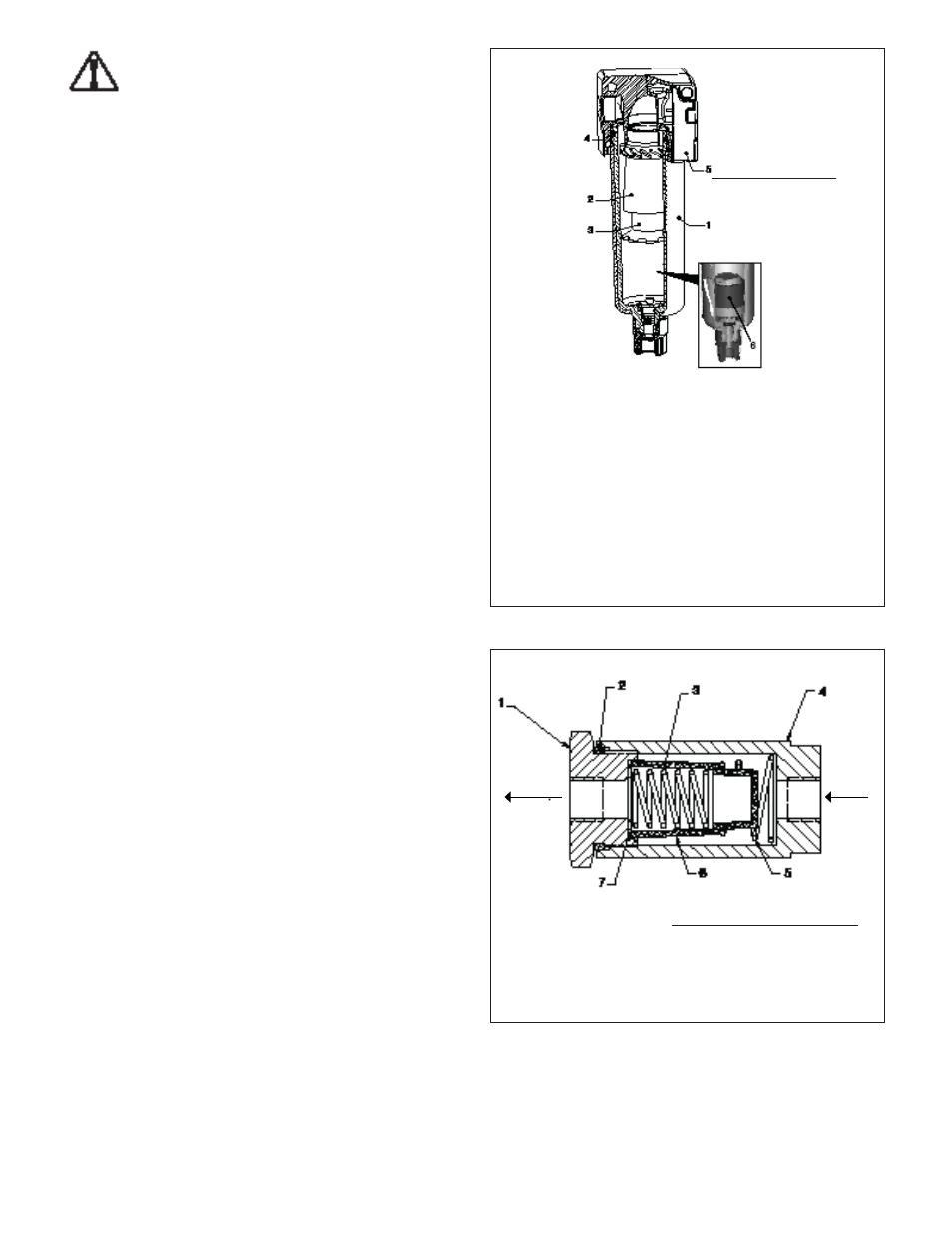

7.5 Hydraulic Filter

Remove and inspect the hydraulic fi lter element at every oil

change. The element can be cleaned and reused if it is in good

condition. However, a new element should be installed if the old

element is damaged or has been cleaned more than three times.

Check the element if a noticeable drop in pump performance

occurs. See Figure 10 for parts diagram.

Figure 9, Air Filter Bowl Details

Figure 10, Hydraulic Filter Details

Key:

1. Auto-Drain Bowl Assy. (Camozzi P/N C238-F11/3)

2. Baffl e/Element Assy. (Camozzi P/N 60W3302-0035)

3. Filter Element, 25 Micron (Camozzi P/N 70-3302-0034)

4. O-Ring

5. Housing Assy.

6. Auto-Drain (included with item #1)

Note: For additional

information, go to

www.camozzi.com.

Key:

1. End Cap

2. O-Ring

3. Spring

4. Housing

5. Spring

6. Element, 90 Micron (Arrow P/N EK9052V-90)

7. Gasket

OIL OUT

OIL IN

Note: For additional information,

go to

www.arrowpneumatics.com.