Enerpac ATP-Series User Manual

Page 4

4

4.0 PUMP SET-UP

4.1 Oil Reservoir

Check pump oil level prior to start-up. Before checking oil level:

• Be sure that air-shutoff valve is CLOSED and that oil return-to-

tank valve is OPEN. See Figure 1.

• Be sure that the pump hydraulic pressure and air pressure

gauges both indicate zero [0] psi/bar.

The reservoir is FULL when oil level is at the top of the reservoir

as shown in Figure 3. Oil capacity is approximately 1 US gallon

[3,8 liters]. Use Enerpac Type HF Oil.

IMPORTANT: Add oil only when all system components are fully

retracted, or the system will contain more oil than the reservoir

can hold.

Filler Cap

OIL LEVEL

OPEN

CLOSED

FULL

Reservoir

Outlet

Valve

Figure 3, Hydraulic Oil Reservoir

4.2 Air and Hydraulic Connections

WARNING: Before connecting air supply, ensure that

the air-shutoff (on-off) valve is closed (i.e. handle in

vertical position) and that the oil return-to-tank valve is

open. See Figure 1. Also, be sure that the air pressure regulator

is fully turned off, so that pump air pressure gauge indicates zero

[0] psi.

Make connections as required:

• The pump air inlet is located on the air pressure regulator

assembly. It is a standard 1/2" NPT connection.

• The pump hydraulic oil outlet is a 1/4" female BSPP connection.

On pumps used in bolting applications, a female quick-disconnect

coupler is typically installed in the BSPP connection.

4.3 Air Requirements

Pump air consumption is approximately 21 SCFM [113 l/min] of

free air at 100 psi [6,8 bar] oil discharge pressure. At lower air

pressures and higher hydraulic pressures, air consumption will

be reduced proportionally to the fl ow rates indicated.

IMPORTANT: Pump air supply pressure should not exceed 90

psi [6,2 bar] static.

WARNING: The pump air pressure relief valve is factory

set at approximately 90 psi [6,2 bar]. To prevent personal

injury and equipment damage, do not attempt to raise

relief valve setting.

Use only dry and fi ltered compressed air. Use of a water separator

is strongly recommended.

Pump internal components are self-lubricating. Lubricated air is

NOT required.

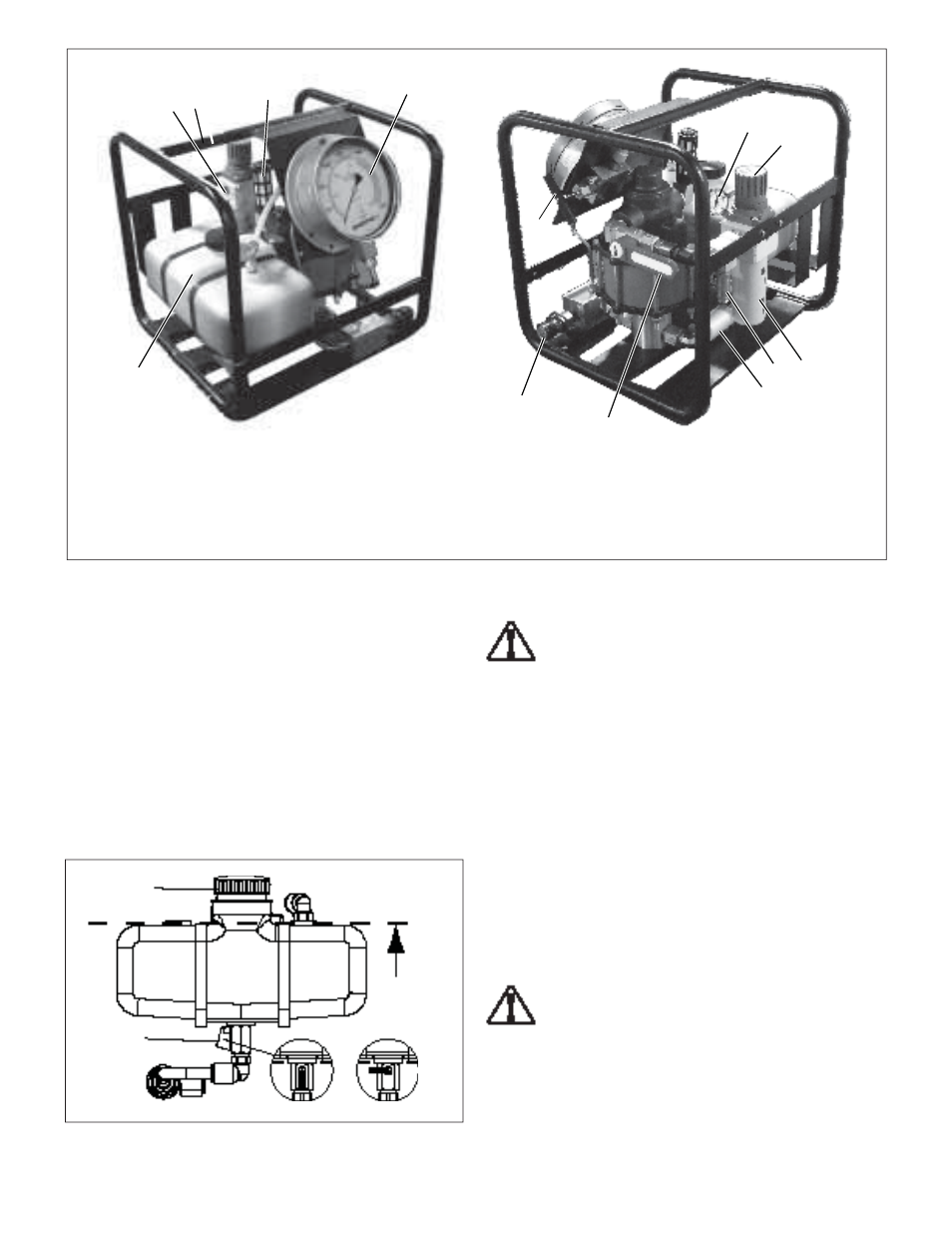

Figure 2, Pump Features and Components (Note: guards and covers removed for illustrative purposes only.)

Key:

1. Air Inlet Connection (1/2 NPT)

2. Roll

Cage

3. Air

Muffl er

4. Hydraulic Pressure Gauge

5. Hydraulic Oil Reservoir

6. Air Pressure Gauge

7. Air Pressure Regulator

8. Filter Bowl Assembly

9. Air Pressure Relief Valve

10. Hydraulic Filter

11. Air-Shutoff Valve

12. Hydraulic Oil Outlet Connection

13. Oil Return-to-Tank Valve

(pressure release to reservoir)

7

8

12

13

11

10

9

6

4

5

2

3

1