Maintenance – Det-Tronics PIRECL Infrared Hydrocarbon Gas Detector PointWatch Eclipse User Manual

Page 26

24

95-8526

14.2

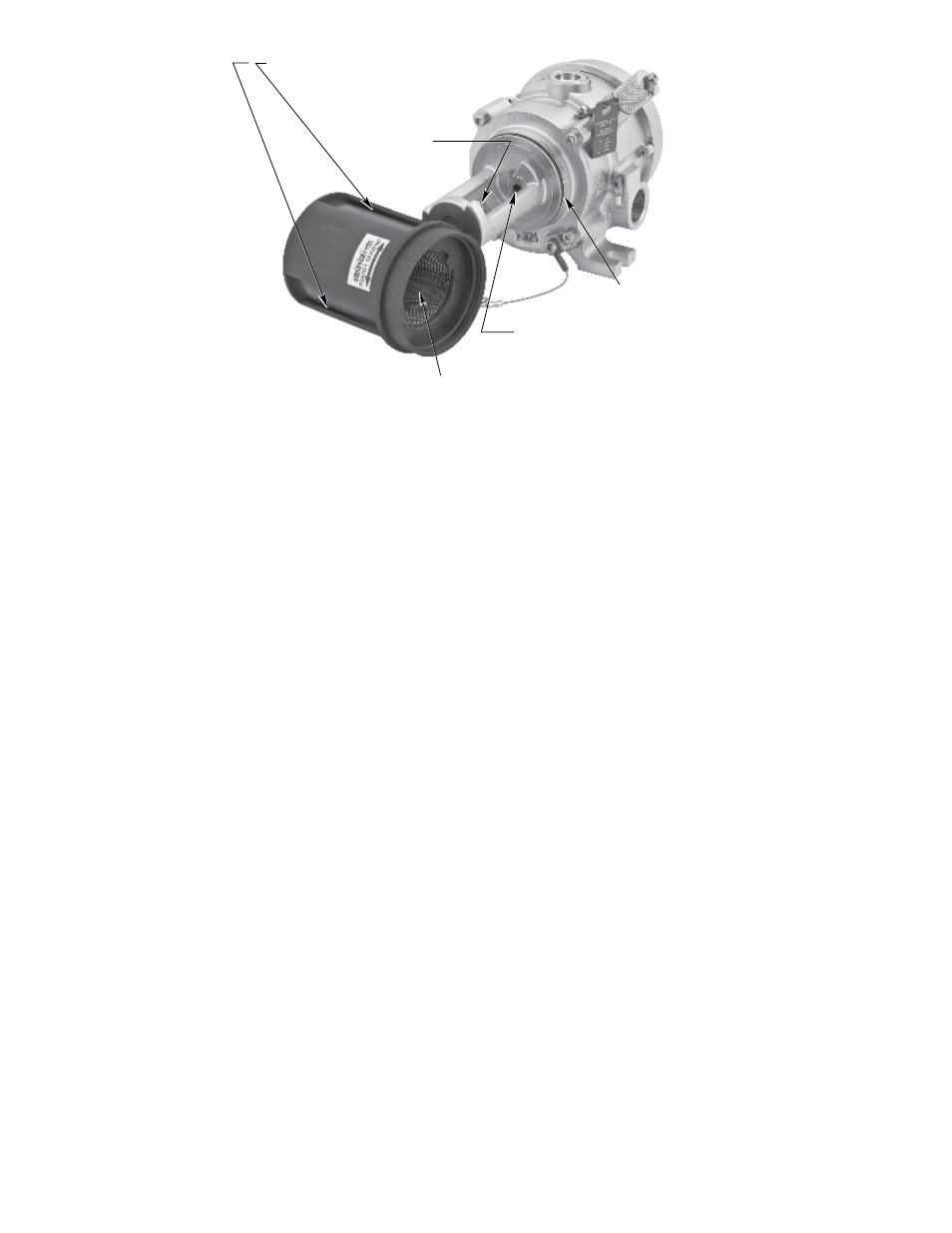

HYDROPHOBIC FILTER

DIFFUSION PATHS INTO MEASUREMENT CHAMBER

MIRROR

IR SOURCE LAMP

AND WINDOW

O-RING

C2059

Figure 22—PointWatch Eclipse with Baffle Removed

maintEnancE

NOTE

Refer to the Model PIRECL Safety Manual

(number 95-8630) for specific requirements

and recommendations applicable to the proper

installation, operation, and maintenance of all

SIL-Certified PIRECL IR gas detectors.

roUtine inSpeCtion

The PointWatch Eclipse detector should be inspected

periodically to ensure that external obstructions such as

plastic bags, mud, snow, or other materials do not block

the weather baffle, thereby impairing the performance

of the device. In addition, the weather baffle assembly

should be removed and inspected to ensure that the

diffusion paths into the measurement chamber are clear.

See Figure 22.

weather baffle Cleaning

Remove the weather baffle assembly and clean with a

soft brush and soap and water. Rinse and allow to dry.

Replace the weather baffle if damaged or if fouling of the

baffle vents is evident.

NOTE

Solvents may damage the weather baffle

assembly. If contamination is not removed using

soap and water, then replacement of the baffle

may be required.

optiCS Cleaning

Cleaning of the Eclipse optical surfaces is normally

required only if an optical fault is indicated.

Thoroughly douse the mirror and window using a liberal

amount of isopropyl alcohol to clear away contaminant

particles. Repeat the alcohol flush to remove any

remaining contaminants. Allow the assembly to air-dry in

a dust-free location.

o-ring

Periodically the O-ring should be inspected for breaks,

cracks and dryness. To test the ring, remove it from the

enclosure and stretch it slightly. If cracks are visible,

it should be replaced. If it feels dry, a thin coating of

lubricant should be applied. See “Spare Parts” section

for recommended lubricant. When re-installing the ring,

be sure that it is properly seated in the groove.

proteCtiVe CapS anD CoVerS

The calibration nozzle cap must always be installed,

except while performing calibration. Also ensure that

the HART Communication Port cover and the wiring

compartment cover are installed and fully engaged.