5 process data – NORD Drivesystems BU0135 User Manual

Page 59

4 Commissioning

BU 0135 GB-2713

Pre-series version

59

4.4.5

Process data

Process data are used to control the motor starter and communicate its status. The transfer of this data is

carried out cyclically. There is only one process data object (PDO) for the motor starter, with a fixed data

length of 1 Byte. A differentiation is made between the setpoint PPO (from the PLC to the starter) and the

actual value PPO (from the starter to the PLC).

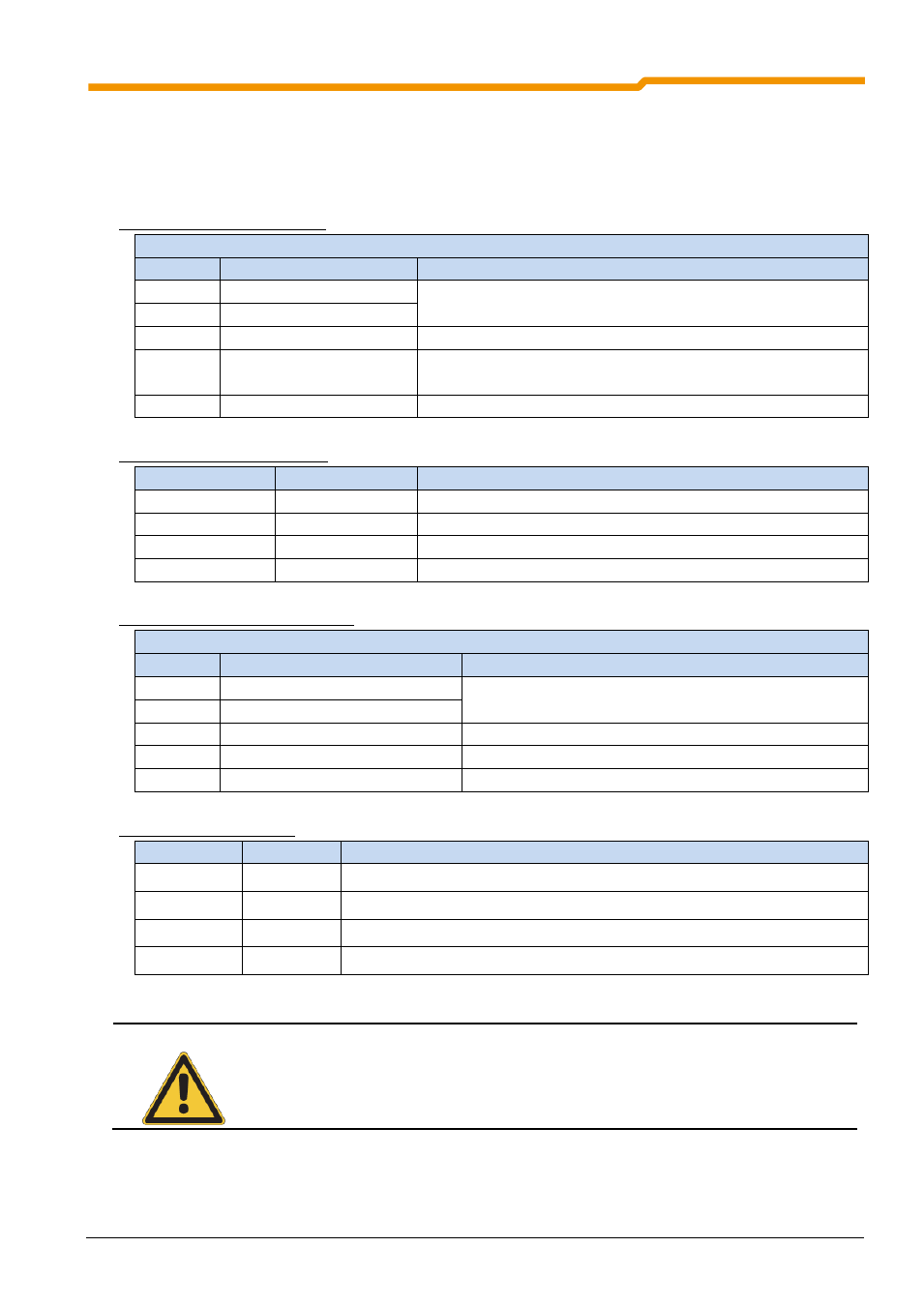

Structure of the setpoint PDO:

Setpoint PPO

Bit

Function

Explanation

Bit 0

Enabled right

See the following table

Bit 1

Enable left

Bit 2

Acknowledge fault

With a change from 0 to 1, a starter fault is acknowledged

Bit 3

Release brake manually

0 = Brake is applied or will be released automatically if required

1 = Brake will be released immediately

Bit 4 – 7

Vacant

These bits do not have any function

Explanation of the Enable bits:

Enabled right

Enable left

Explanation

0

0

Motor is switched off

0

1

A rotating field in the left hand direction is present at the motor

1

0

A rotating field in the right hand direction is present at the motor

1

1

Motor is switched off

Structure of the actual value PDO:

Actual value PPO

Bit

Function

Explanation

Bit 0

Status Bit 0 (Fault)

See the following table

Bit 1

Status Bit 1 (Operation)

Bit 2

Status of initiator 1 (DIN3 / C1)

Shows the logic level at input DIN3

Bit 3

Status of initiator 2 (DIN4 / C2)

Shows the logic level at input DIN4

Bit 4 – 7

Vacant

These bits do not have any function

Explanation of status bits:

Status Bit 1

Status Bit 0

Status

0

0

Error active

0

1

Standby (motor stationary)

1

0

Warning (but motor running)

1

1

Run (motor running without warning)

WARNING

In case of malfunction (interruption of communication or break in the PROFIBUS

cable) the motor starter switches off automatically. In order to prevent a re-start

on restoration of communication, the PROFIBUS master must actively set the

control bits to "Zero".