Design features & information, Pipework design, Refrigeration schematic – Airedale TurboChill FreeCool 200kW - 1830kW User Manual

Page 35: Chillers turbochill™ air cooled and freecool, Introduction

35

Chiller Technical Manual 7525355 V1.1.0_04_2013

Introduction

Chillers

TurboChill™ Air Cooled and FreeCool

Design Features & Information

Pipework Design

Due to the unique oil free operation of the Turbocor compressor, the need for oil entrainment is eliminated. As pipe work

is not required to be sized for oil return it is possible to size pipe work for minimal pressure losses through the system

with maximum cooling capacity and optimised unit EER.

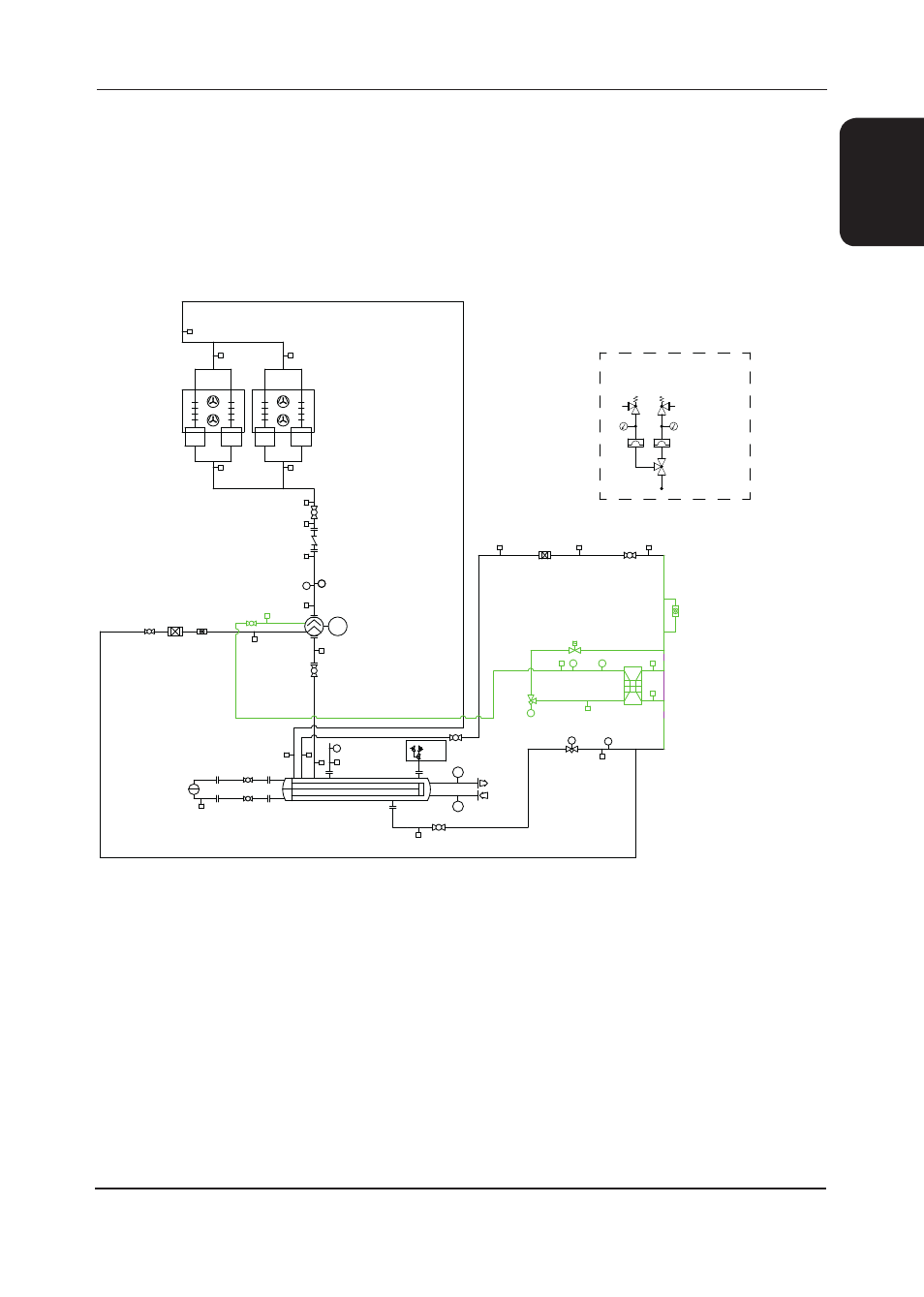

Refrigeration Schematic

Note: Schematic above is for a single circuit machine.

key

1

Turbochill flooded schematic

2

Flooded evaporator

3

Schrader connection

4

Centrifugal compressor

5

Shut off valve

6

Filter drier

7

Sight glass

8

Electronic expansion valve (economiser circuit

only)

9

Condenser section

10

Level transmitter

11

Water connections (Inlet /Outlet)

12

Liquid line

13

Suction line

14

Dual pressure relief valves

15

Liquid level control valve

16

High pressure switch

17

Rotalock adapter

18

Liquid pressure transmitter

19

Solenoid valves

20

Low pressure switch

21

Economiser pressure transducer

22

Temperature sensor

23 Economiser

24

Economiser line

25

Non return valve

26

Liquid level sensor

M

PZH

S

PZH

S

S

S

LT

S

S

PSL

Ti

Ti

M

S

S

S

S

S

S

S

S

S

S

PT

S

S

S

S

S

TCE

S

PT

TT

S

S

S

S

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

5

5

5

5

5

5

5

5

5

9

9

18

23

6

6

7

17

17

17

17

17

20

8

7

21

2

16

26

19

12

15

14

13

11

24

12

25

24

24

22

1

DUAL PRESSURE RELIEF VALVE

ASSEMBLY WHEN REFRIGERANT CHARGE IS

ABOVE 300KG PER CIRCUIT

PRESSURE

INDICATOR

BURSTING DISC

THREE WAY

VALVE

14