Chillers turbochill™ air cooled and freecool – Airedale TurboChill FreeCool 200kW - 1830kW User Manual

Page 17

17

Chiller Technical Manual 7525355 V1.1.0_04_2013

Introduction

Chillers

TurboChill™ Air Cooled and FreeCool

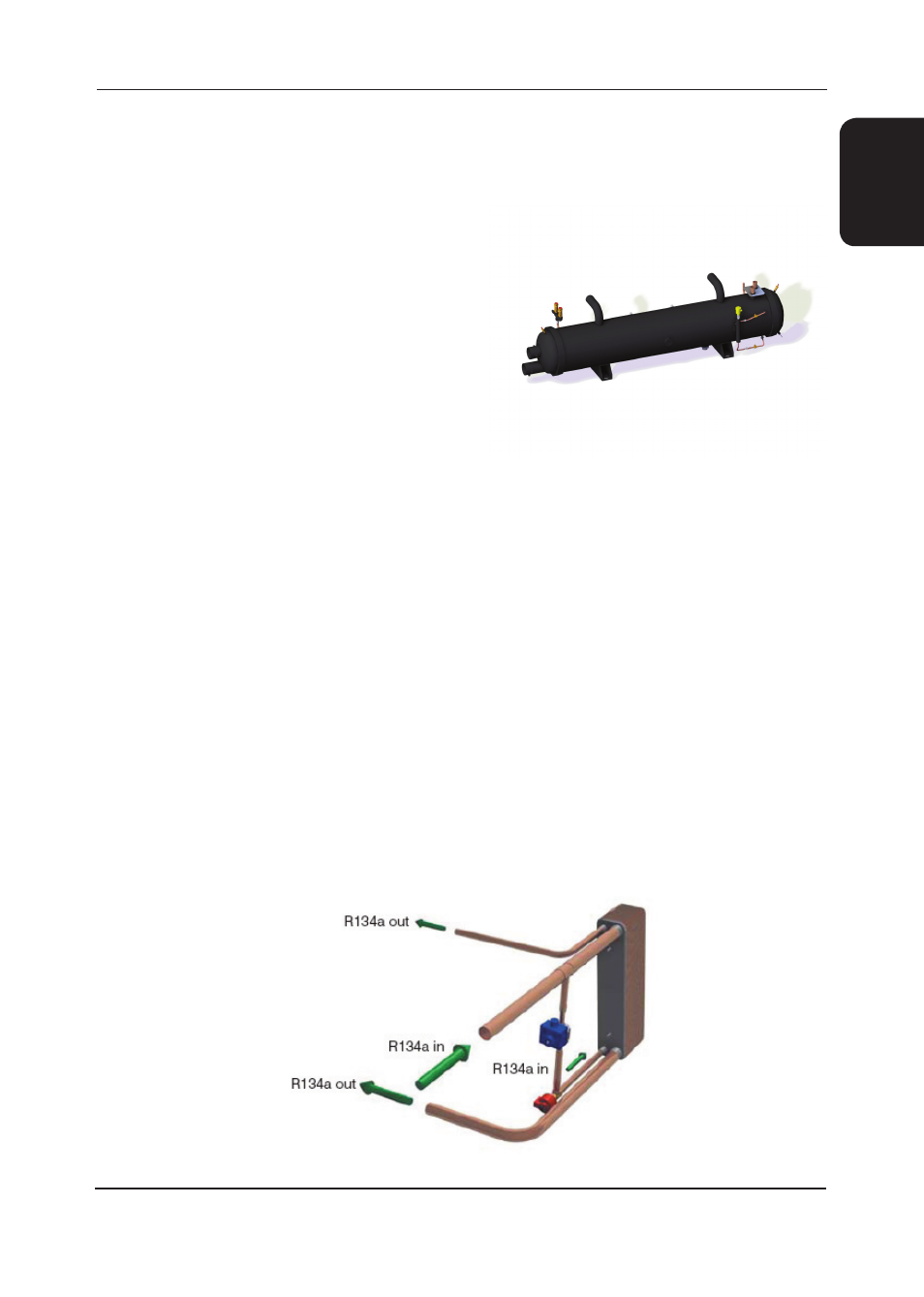

Evaporator

Flooded evaporator incorporating an internal round tube heat

exchanger. This heat exchanger is used to further sub-cool

refrigerant leaving the condenser extending the potential cooling

capacity and as a result, efficiency of the system. At the same time

suction gas vapour that passes over the heat exchanger within the

shell is superheated to a higher temperature, eliminating the risk of

wet vapour returning to the compressor.

The heat exchanger is insulated with closed cell polyurethane

foam which is to Class O fire rating and the material is UV

resistant.

The flooded evaporator results in significant energy savings in

compressor operation particularly at part load.

Two immersion heater(s) and thermostat protect the evaporator

against freeze up in ambient temperatures down to -20°C. (in

compliance with Airedale freeze protection policy).

Connections for External Trace Heating (240V / 500W available).

Compressors and evaporator shall be mounted on a rigid

galvanised heavy duty sub frame. Fully weatherproofed electrical

panels are situated at one end of the unit.

Actuated Suction Ball Valve(s)

To protect the compressors against liquid migration, actuated

suction line ball valves shall be fitted. This protects the

compressors when their is no cooling demand by keeping the

refrigerant in the evaporator, even if water is still flowing through

the unit.

Economiser Circuit for Increased Part Load Efficiency

The addition of an economiser circuit provides increased cooling and enhances EER, in full and part load operation.

Sub cooled liquid is expanded using a dedicated EEV (electronic expansion valve) to medium pressure and passed

through one side of a plate heat exchanger.

Through the other side flows the ‘normal’ pressure liquid.

The result is that the sub cooling of the liquid entering the system EEV is increased, which improves evaporator

performance and at the same time the suction pressure within the compressor body is lifted, improving compressor

efficiency.