Chillers turbochill™ air cooled and freecool, Trou ble sh oo tin g, Alarms – Airedale TurboChill FreeCool 200kW - 1830kW User Manual

Page 139

139

Chiller Technical Manual 7525355 V1.1.0_04_2013

Trou

ble

sh

oo

tin

g

Chillers

TurboChill™ Air Cooled and FreeCool

Alarms

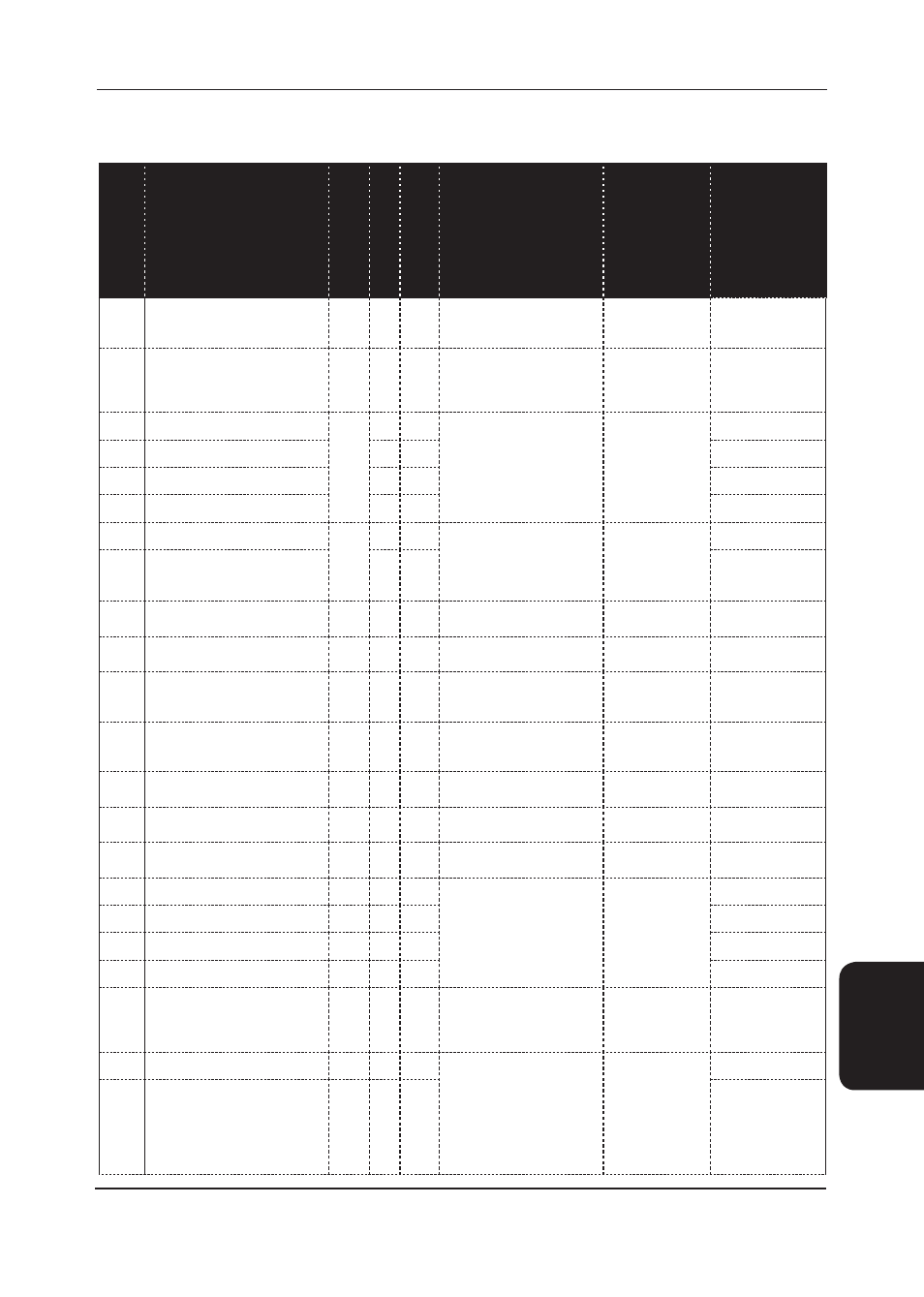

Code

Description

Auto Reset

Unit Disabled

Component Disabled

Cause

Action

Default Alarm Type

AL078 SCR Temp. Comp.4

•

•

Indicates insufficient cooling

to the SCR plate

Check: alarms

limits in the

compressor

1 = Non critical

AL079 System Lockout Comp.4

•

When a SCR/inverter/cavity

temperature fault occurs more

than 3 time in 30minutes

Check: motor

cooling line and

solenoids valves /

cycle power

1 = Non critical

AL080 Hours Limit Comp.1

•

•

The hours run for the

compressor has exceeded the

threshold

If component

is functioning

correctly perform

maintenance and

reset hours

1 = Non critical

AL081 Hours Limit Comp.2

•

1 = Non critical

AL082 Hours Limit Comp.3

•

1 = Non critical

AL083 Hours Limit Comp.4

•

1 = Non critical

AL084 Hours Limit Pump 1

•

•

The hours run for the pumps

has exceeded the threshold

If component

is functioning

correctly perform

maintenance and

reset hours

1 = Non critical

AL085 Hours Limit Pump 2

•

1 = Non critical

AL086 Liquid Level 1 Fault

•

•

Circuit 1 liquid level sensor

has gone out of range

Check: the sensor

/ Wiring

1 = Non critical

AL087 CW Valve Feedback

•

•

Valve failed to open

Check: valve

operation / Wiring

1 = Non critical

AL088 Cond. Pressure2 Fault

•

• •

Circuit 2 condensing pressure

sensor has gone out of its

operating range

Check: wiring /

Sensor

1 = Non critical

AL089 Low Pressure 2 Switch

•

Circuit 2 suction pressure is

below 0.5 bar

Check: refrigerant

charge / EEV

operation

2 = Critical

AL090 High Cond. Pressure 2

•

Circuit 2 condensing pressure

is higher than 13.6 Bar

Check: Condenser

/ Condenser Fans

1 = Non critical

AL091 Liquid Level 2 Fault

•

• •

Circuit 2 liquid level sensor

has gone out of range

Check: wiring /

Sensor

1 = Non critical

AL092 Evap.Inlet Temp. Fault

•

• •

The sensor has gone out of its

operating range

Check: wiring /

sensor

1 = Non critical

AL093 Serious Alarm Comp.1

•

The compressor has been in

alarm more than 5 times in 2

hours

Check the

operation of the

compressor /

circuit

1 = Non critical

AL094 Serious Alarm Comp.2

•

1 = Non critical

AL095 Serious Alarm Comp.3

•

1 = Non critical

AL096 Serious Alarm Comp.4

•

1 = Non critical

AL097 Evap. Low Flowrate

• •

The evaporator flow rate is

equal to or less than 20% of

design

Check the

evaporator strainer

or for any other

blockages

1 = Non critical

AL098 Liq. Valve EVD1 Alarm

•

The electronic expansion

valve driver used to position

the flooded evaporator liquid

level control valve is in alarm

Check the wiring

between the EVD

and the liquid

level control

valve / check

the operation of

the control valve

stepper motor

2 = Critical

AL099 Liq. Valve EVD2 Alarm

•

2 = Critical