Chillers turbochill™ air cooled and freecool, Tr ou ble sh oo tin g, Alarms – Airedale TurboChill FreeCool 200kW - 1830kW User Manual

Page 136

136

Chiller Technical Manual 7525355 V1.1.0_04_2013

Tr

ou

ble

sh

oo

tin

g

Chillers

TurboChill™ Air Cooled and FreeCool

Alarms

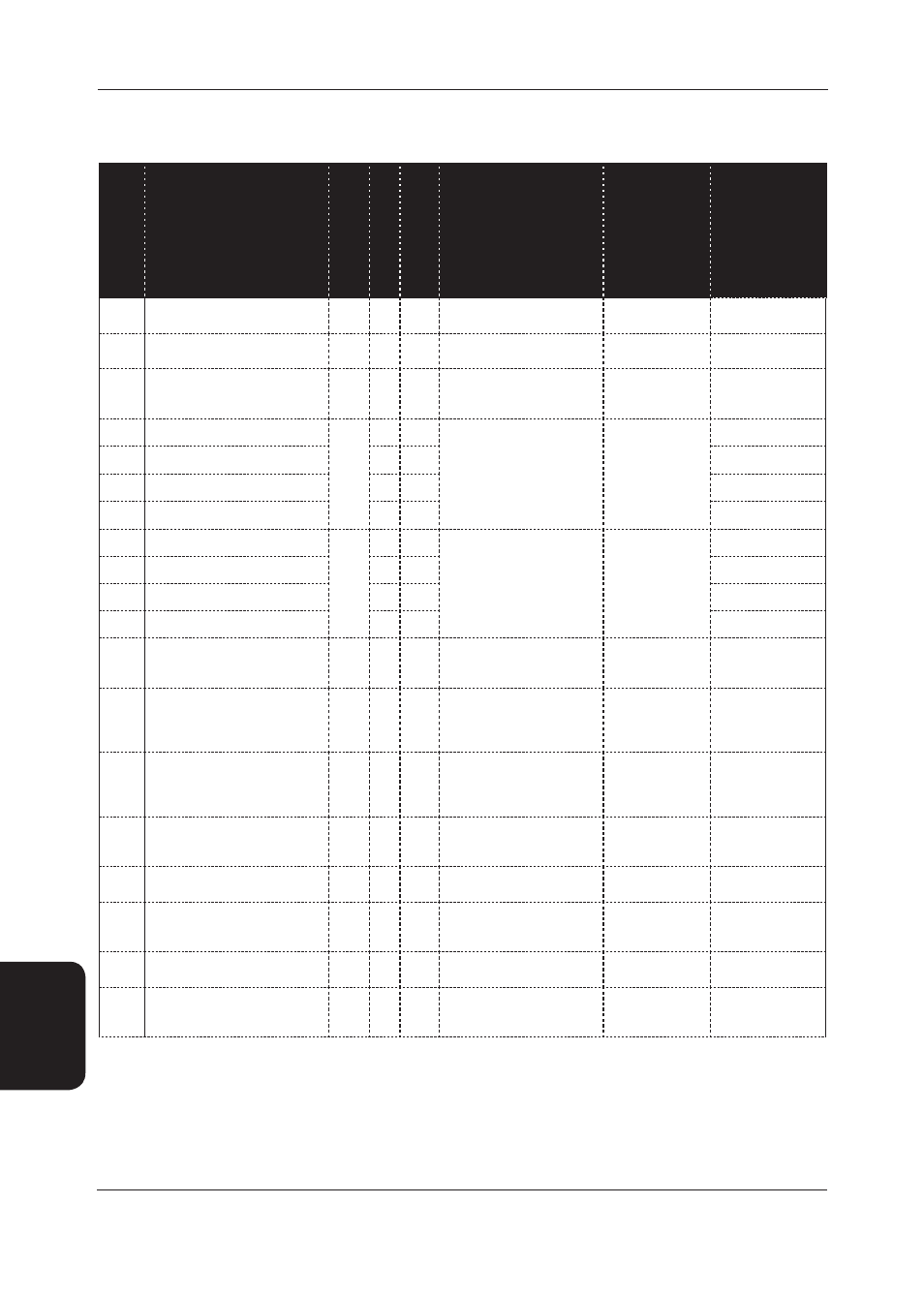

Code

Description

Auto Reset

Unit Disabled

Component Disabled

Cause

Action

Default Alarm Type

AL025 Low Supply Temperature

•

• •

The supply water temperature

is too low

Check: flow rate /

Unit TD

1 = Non critical

AL026 High Cond. Pressure 1

•

• •

Circuit 1 condensing pressure

is higher than 13.6Bar

Check: condenser

/ condenser fans

1 = Non critical

AL027 pCO5 Module Offline

•

•

Communication to the pCOe

expansion module has been

lost

Check:

communications

link / wiring

1 = Non critical

AL028 Leak Detector 1 Fault

•

•

The output from the leak

detector is out of range

Check: leak

detector / wiring

1 = Non critical

AL029 Leak Detector 2 Fault

•

1 = Non critical

AL030 Leak Detector 3 Fault

•

1 = Non critical

AL031 Leak Detector 4 Fault

•

1 = Non critical

AL032 Possible Leak Comp.1

•

The reading from the leak

detector is above the

threshold

Check: pipe work

around the leak

detector

1 = Non critical

AL033 Possible Leak Comp.2

1 = Non critical

AL034 Possible Leak Comp.3

1 = Non critical

AL035 Possible Leak Comp.4

1 = Non critical

AL036 Inverter Temp. Comp.1

•

•

The temperature of the

compressor inverter is high

Check: liquid line

to the compressor

/ solenoid valves

1 = Non critical

AL037 Discharge Temp. Comp.1

•

•

The temperature of the

discharge gas is high

Check: refrigerant

charge / discharge

temperature

sensor

1 = Non critical

AL038 Suction Press. Comp.1

•

•

The suction pressure is too

high / low at the compressor

Check: charge

/ system load /

sensor / suction

strainer

1 = Non critical

AL039 Discharge Press.Comp.1

•

•

The discharge pressure has

exceeded it limit

Check: The sensor

/ condenser/ shut

off valves

1 = Non critical

AL040 3Ph. Current Comp.1

•

•

Indicates there maybe an

excessive load on the system

1 = Non critical

AL041 Cavity Temp. Comp.1

•

•

The cavity temperature inside

the compressor is high

Check: the liquid

cooling line /

solenoid valve

1 = Non critical

AL042 Air/Water Temp. Comp.1

•

•

There maybe insufficient

water flow due to air gaps

Check: Sensor

limits

1 = Non critical

AL043 Compress. Ratio Comp.1

•

•

The compression ratio of the

compressor is out of range

Check: condenser

/ evaporator loads

and settings

1 = Non critical