Troubleshooting, Troubleshooting 132, Chillers turbochill™ air cooled and freecool – Airedale TurboChill FreeCool 200kW - 1830kW User Manual

Page 132: Tr ou ble sh oo tin g

132

Chiller Technical Manual 7525355 V1.1.0_04_2013

Tr

ou

ble

sh

oo

tin

g

Chillers

TurboChill™ Air Cooled and FreeCool

Troubleshooting

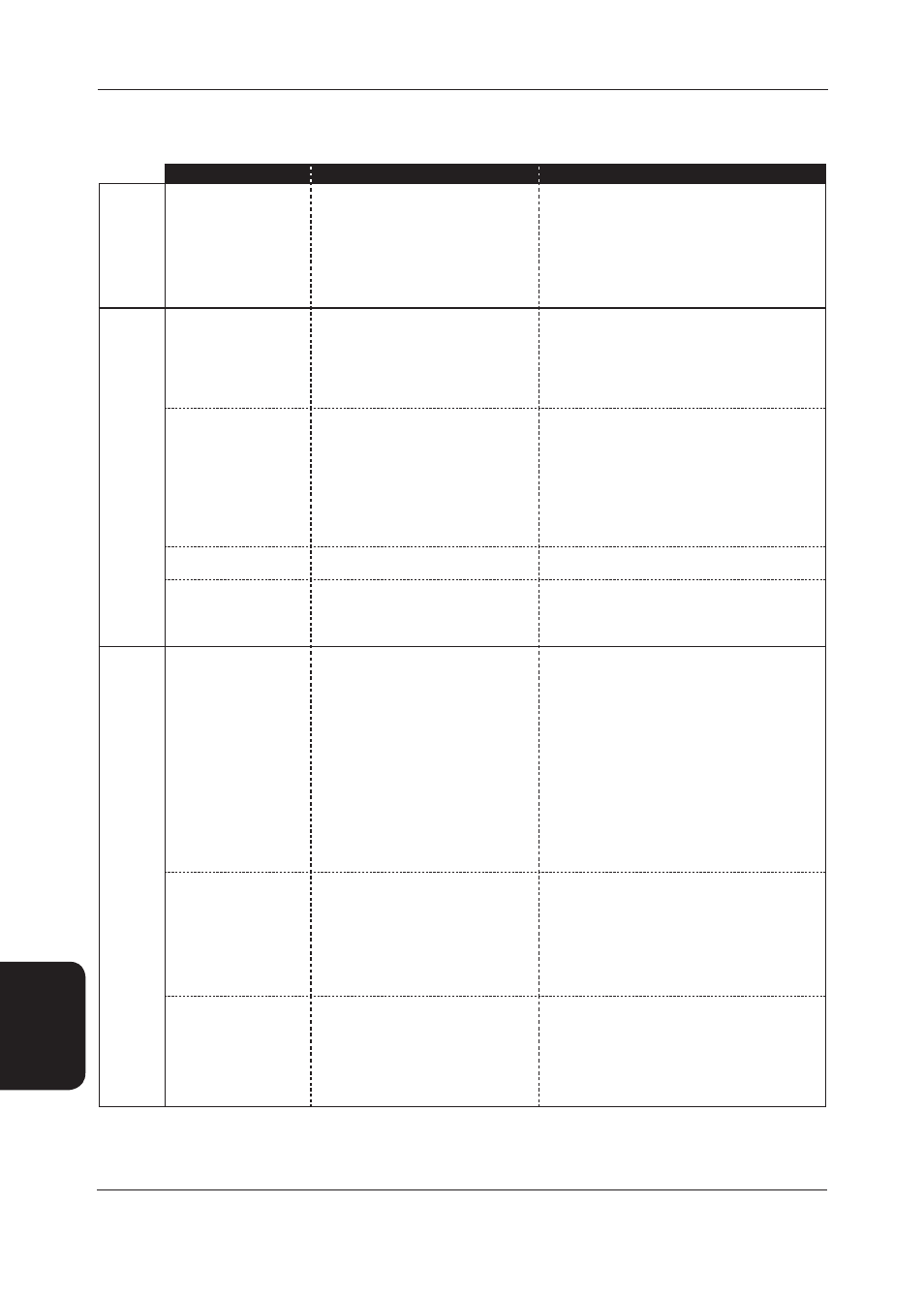

Fault

Possible Cause

Remedy / Action

General

Unit will not start

No power.

Check power supply to the controller.

Wired incorrectly.

Check wire connections in accordance

with wiring diagram.

Loose wires.

Check all wires, connections, terminals etc.

Remote on/off.

Check that the remote on/ off

is at the on position.

Refrigeration

Compressor not

operating

No power to compressor.

Check isolator, fuses, MCBs, contactor

and control circuit wiring.

Low pressure cut-out operated (large

or complete loss of refrigerant charge).

Recover refrigerant, repair, pressure

test, evacuate and recharge system.

Compressor showing

fault on controller.

Determine fault, refer to alarm

codes for further information.

Head pressure too high

/ HP cut-out operated

Condenser coil clogged or dirty.

Clean condenser.

Overcharge of refrigerant. Normally

troublesome in warm weather.

Remove excess refrigerant from system using

correct refrigerant handling techniques.

Air or other non-condensable

gas in system.

Evacuate system and re-charge

with new refrigerant.

Head pressure controller faulty.

Check EC fan control module - if faulty - replace.

Fan not operating or

operating inefficiently.

Check motor - if faulty - replace.

Head pressure too low

Fan operating too fast in

low ambient conditions.

Check EC fan control module - if faulty - replace.

Suction pressure

too low

Flash gas (bubbles in sight

glass) at liquid line.

Investigate for refrigerant leaks, repair, pressure

test, evacuate and re-charge system.

Clogged filter drier (pressure /

temperature drop across it).

Replace drier cores.

Condenser

Condenser fan not

operating - power on

Power supply failure.

Check power supply at circuit breaker.

Wiring to motors.

Check voltage at motor terminals.

Motor / fan assembly jammed.

Isolate unit and check free rotation of

motor/fan assembly. If faulty - replace.

Motor internal overheat

protector tripped.

Carry out continuity check at terminals

“TK” in motor terminal box.

If tripped and motor hot - check to see if the

motor bearings have seized / fan difficult to turn.

If tripped and motor cold - replace motor.

Faulty motor windings / capacitor.

Motor humming would indicate fault in

motor or capacitor. Check windings for

continuity and if OK replace capacitor.

Minimum speed set too low.

Adjust head pressure controller to suit.

Condenser fan

runs too fast

High ambient condition or

excessive re-circulation of air

around condenser coil.

Check installation against design.

Minimum set speed setting incorrect.

Adjust as necessary.

Incorrect pressure sensor setting.

Adjust via microprocessor.

Faulty EC fan.

Replace fan.

Faulty pressure sensor.

Replace sensor.

Condenser fans

runs only slowly

Incorrect pressure setting.

Adjust via microprocessor.

Faulty EC fan.

Replace fan.

Faulty pressure sensor.

Replace sensor.

Motor / capacitor faulty.

Replace.

Motor wired incorrectly.

Check against wiring diagram

- correct as required.