KROHNE IFC 110 Converter User Manual

Page 65

Part C Special applications, functional checks, service, and order numbers Sect. 6.9

05/2003

IFC 110 F

65

6.9

Empty pipe detection EPD

The signal converter is equipped as standard with an EPD (Empty Pipe Detection)

which only needs to be activated as and when required.

To ensure proper functioning, the following requirements need to be met:

Type

of signal cable

Electrical conductivity

of process liquid

Nominal size

of flow sensor

Max. length

of signal cable

A = Type DS

> 200 µS/cm

≥ DN 25 / ≥ 1“

< 20 m / 65 ft

B = Type BTS

> 50 µS/cm

≥ DN 25 / ≥ 1“

< 20 m / 65 ft

Settings for empty pipe detection (EPD)

• Fct. 3.06 APPLICATION • EMPTY PIPE • YES (switched on) • NO (switched off)

The calibration mode must be run through during initial start-up!

• If“YES“ selected, the impedances for EMPTY and FULL PIPE need to be determined.

• Select subfunction VALUE FULL and CALIB. YES (determine impedance for “full pipe“)

WAIT (approx. 20 s)

• Select subfunction VALUE EMPTY and CALIB. YES (determine impedance for “empty pipe“)

WAIT (approx. 20 s)

• Store values after completion of calibration for “Full” and “Empty” values; quit operator control

after the second calibration.

When the electrodes are not wetted (= empty pipe), typically a response time of approx. 20

seconds is required before “empty pipe“ is indicated. In this time undefined display values and

output signals are possible.

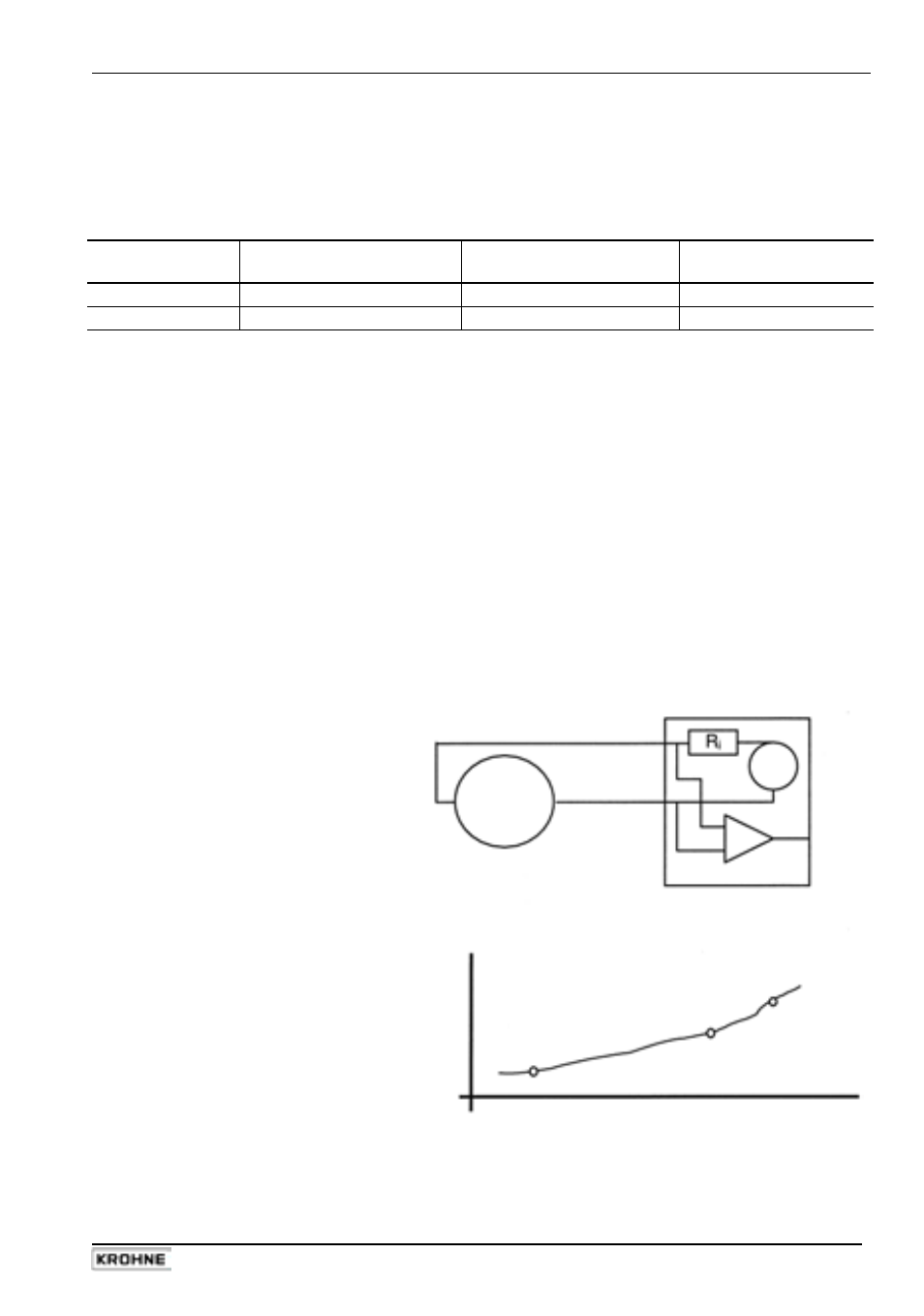

Functional description

A high-resistance AC voltage is applied

to the electrodes. The process liquid in

the measuring tube forms a voltage

divider together with the internal

resistance of the circuit. The voltage

ratio is measured and weighted (see

figure on right). Impedance and length

of electrode cable will also affect the

result.

The result is a numerical value

proportional to the impedance at the

input. The switching point of the Empty

Pipe Detector is defined when the

system is calibrated for “full pipe“ and

“empty pipe“(at approx. 2/3 of the range

between the two calibration points). In

order to function properly there must be

a difference of at least “10“ between the

two calibration points. In operation, the

display indicates in the range between

0 and 150 (non-dimensional). The value

for “FULL PIPE“ must be lower than that

for “EMPTY PIPE“.

Display

Switching point

Impedance

EMPTY

PIPE

FULL

PIPE

Process

liquid