KROHNE CORIMASS G-MFM 4085 EN User Manual

Page 90

90

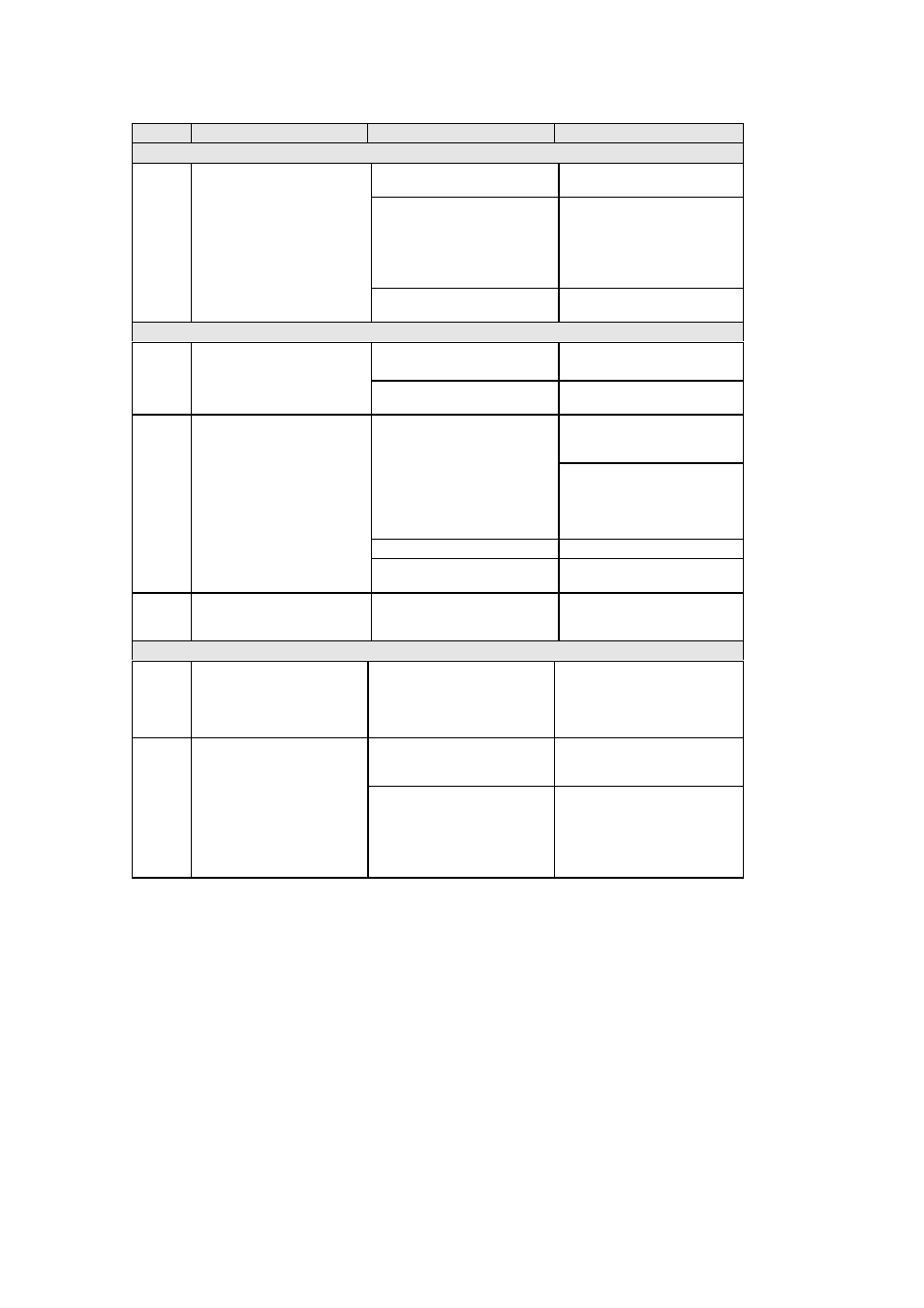

Group

Fault / Symptom

Cause

Remedy

Group E

E1

Control input does not

function

Connection / polarity

incorrect.

Correct as per Sect. 2.3

Programming incorrect

Correct the programming

as per Fct. 3.6.1 - 3.6.2. Test

as per Fct. 2.15. If test is

faulty, the output is faulty.

Replace converter or call

Krohne Service.

Control input switched off.

Switch on as per Fct.

3.6.1

Group ST

ST1

Display keeps returning

to ”test”. (during start-up)

Poor/intermittant power.

Supply to meter.

Check incoming supply

Hardware failure

Replace converter or call

Krohne Service.

ST2

Display returns to ”Start

up” and the status arrow is

illuminated.

Possible poor mechanical

installation.

Check install factor and

correct installation as per

Section. 1

Check the status list in

reset/quit menu as per

Section 4.5 and acknow-ledge

the error message.

Primary Sensor faulty

Check as per Sect. 8.8

Fuse F11 blown. (negative

analog voltage).

Call Krohne Service.

ST3

Display returns to Start-

up and the primary sensor is

noisy.

Sensor cannot vibrate

freely due to poor mechanical

installation.

Correct installation as per

Section 1 and try again.

Group OP

OP1

Installation factor

larger

than value given in Sect.

1.2.3

Mechanical installation not

correct or air bubbles in

process fluid. External

influences due to pumps,

motors, etc.

Check installation and

correct if necessary (see

Section 1). Flush process pipe

work to get rid of air.

OP2

Display indicates a flow-

rate during zero setting.

Valves closed.

Valves not shut tight or air

in process fluid.

Check valves for tight shut-

off. Flush lines with high

velocity.

Zero calibration not OK

Check that flow is zero and

pipe is full without air bubbles.

Do automatic calibration as per

Section 5.1 and ensure that a

”0” is programmed in the zero

set function.