KROHNE CORIMASS G-MFM 4085 EN User Manual

Page 9

9

The following values are a guideline to a good installation:

With the meter filled with water, the values should be less than the figure indicated.

Meter Size

Installation factor

Non Ex

•

Installation factor

Ex

10 G +

20

200

100 G +

10

150

300 G +

20

400

800 G +

20

300

1500 G +

30

300

3000 G +

40

400

•

The higher installation factor for Ex instruments is due to the power limiting of the Zener

barriers in the Exciter circuit, and does not mean bad installation.

•

Product with higher density or entrained gas will exhibit higher installation factors.

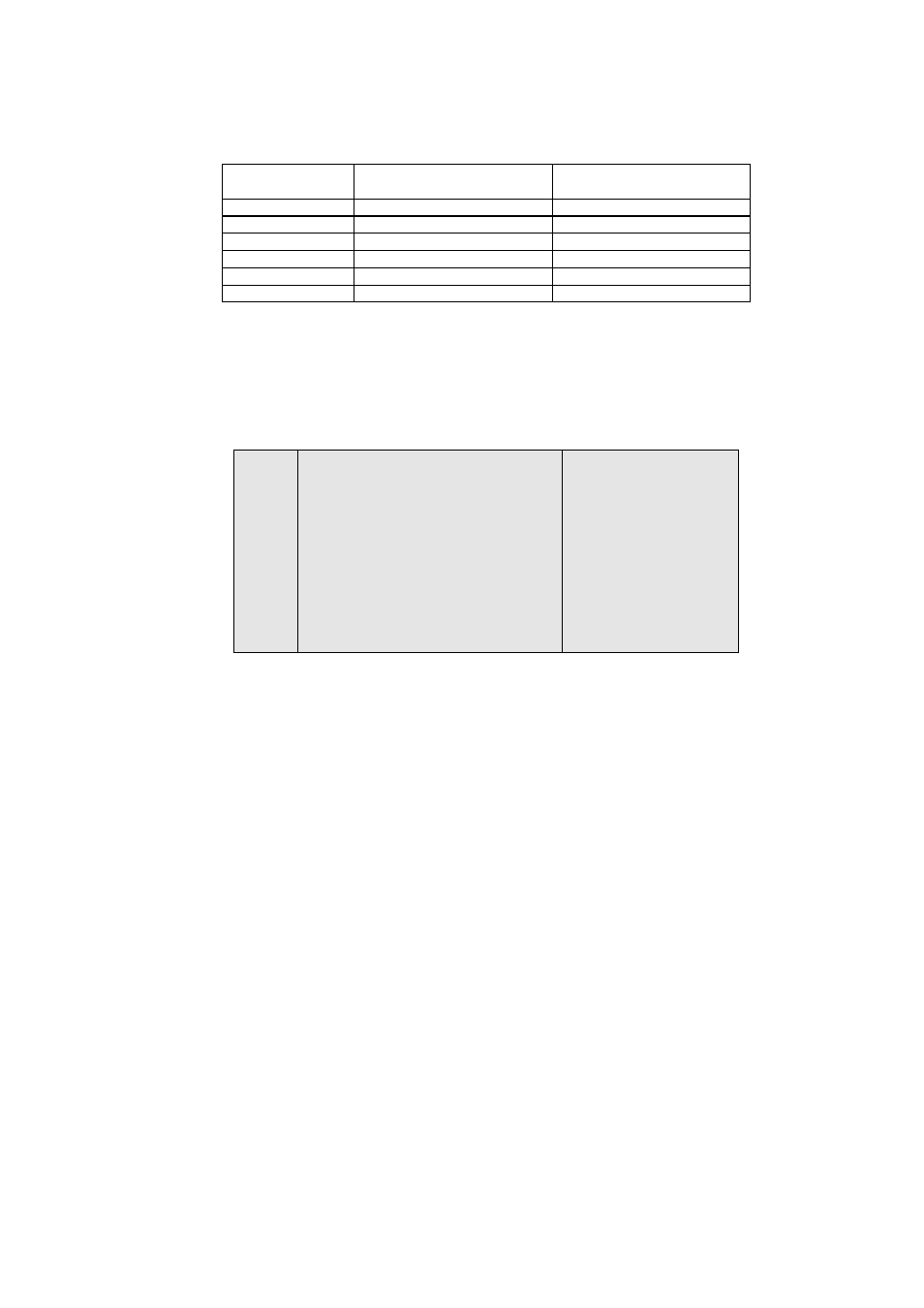

Use the following procedure to check the installation factor. Warm up the electronics for at least

30 minutes. Flush the meter with water or product to ensure that all trapped air has been

removed.

Key

Display

Line 2

Display

Line 2

→

Fct. (1).0

OPERATOR

↑

Fct. (2).0

TEST

→

Fct. 2.(1)

TEST DISP:

6

×

↑

Fct. 2.(7).0

TEST: TRANSD:

→

Fct. 2.7.(1)

SENSOR A

3

×

↑

Fct. 2.7.(4)

INSTAL:FACT:

→

Fct. xxx

Display of installation factor

LEVEL

3

×

↵

Fct. 2.7.(4)

INSTAL:FACT

↵

Display

Note: Terms in brackets are flashing on the display.

1.2.5 Standard flange sizes

The following is a list of flanges for the meters, which are supplied as standard.

10 G+

100 G+

300 G+

800 G+

1500 G+

3000 G+

DN 10 PN 40 / ½” ANSI 150

DN 15 PN 40 / ¾” ANSI 150

DN 25 PN 40 / 1” ANSI 150

DN 40 PN 40 / 1½” ANSI 150

DN 50 PN 40 / 2” ANSI 150

DN 80 PN 40 / 3” ANSI 150