Caution – Yokogawa EJX930A User Manual

Page 72

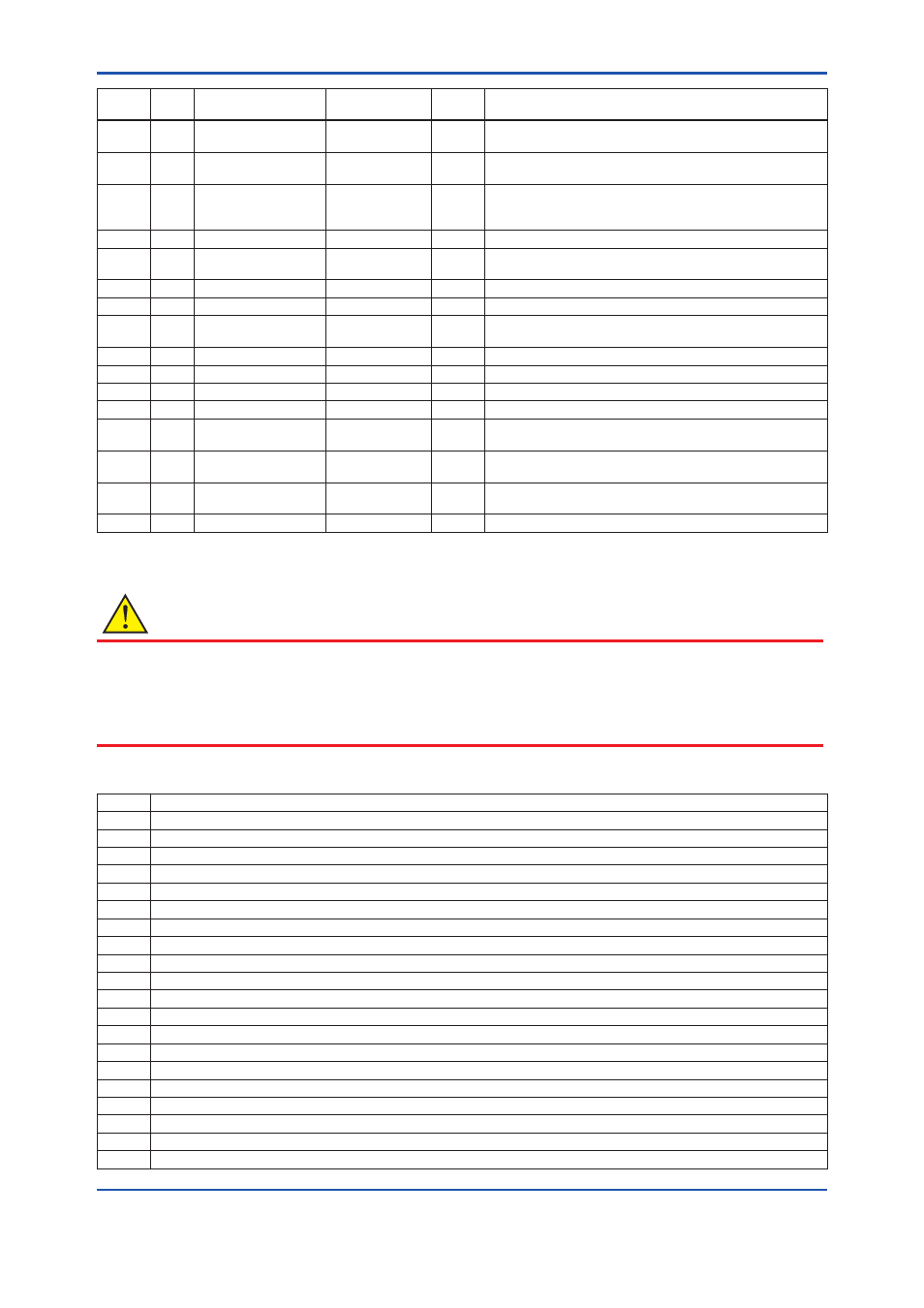

<9. Parameter Lists>

9-8

IM 01C25R03-01E

Relative

Index Index

Parameter Name

Factory Default

Write

Mode

Explanation

38

2338 PIPE_EXPANSION_

COEF

*1

0.00001148

O/S

Indicates the pipe linear expansion coefficient value.

39

2339 PIPE_REF_

TEMPERATURE

*1

20

O/S

Indicates the temperature during pipe inner diameter

measurement.

40

2340 BASE_DENSITY_

FOR_VOLUME_

FLOW

*1

1.250380253

O/S

Indicates the density for conversion of the volume flow unit.

41

2341 FLOW_CONFIG1

*1

—

O/S

Indicates the compensation coefficient of the flow coefficient.

42

2342 FLOW_CONFIG2

*1

—

O/S

Indicates the compensation coefficient of the expansion

compensation coefficient.

43

2343 FLOW_CONFIG3

*1

—

O/S

Indicates the precision compensation coefficient.

44

2344 FLOW_CONFIG4

*1

—

O/S

Indicates the viscosity compensation coefficient.

45

2345 CORRECTION_

VALUE

*1

—

—

Indicates the flow compensation value.

46

2346 CONFIG_SOFT_REV

*1

O/S

Space Used as a record of the setup tool software version.

47

2347 CONFIG_DATE

*1

O/S

Space Used as a record of the setting date.

48

2348 CONFIG_WHO

*1

O/S

Space Used as a record of the setter.

49

2349 CONFIG_STATUS

*1

O/S

Space Used as a memo.

50

2350 CONFIG_

VSTRING32

*1

O/S

Space Used as a memo.

51

2351 CONFIG_

VSTRING16

*1

O/S

Space Used as a memo.

52

2352 CONFIG_

OSTRING32

*1

O/S

Space Used as a memo.

53

2353 CONFIG_OSTRING2

*1

O/S

Sum value of precision flow setting data.

*1: These are the parameters which are allowed to be written only by EJXMVTool. Changes using other parameter setting tools or

handheld terminals may cause Check Sum Error (AL83).

CAUTION

Indexes 2331 to 2353 are parameters for precision volume calculation, and data calculated by the MV

setup tool must be written to these parameters. For this reason, these parameters must not be written with

data other than that from the MV setup tool.

When parameters marked by the “*1” symbol are written individually, a sum value error and an alarm

occurs.

Table 9.1

Primary Device Codes

Code

Primary Device

1

Fixed Mode

2

Orifice Corner Taps [ISO5167-1 1991]

3

Orifice Corner Taps [ISO5167-2 2003]

4

Orifice Corner Taps [ASME MFC-3M 1989]

5

Orifice Flange Taps [ISO5167-1 1991]

6

Orifice Flange Taps [ISO5167-2 2003]

7

Orifice Flange Taps [ASME MFC-3M 1989]

8

Orifice Flange Taps [AGA No.3 1992]

9

Orifice D and D/2 Taps [ISO5167-1 1991]

10

Orifice D and D/2 [ISO5167-2 2003]

11

Orifice D and D/2 [ASME MFC-3M 1989]

12

ISA1932 nozzle [ISO5167-1 1991/ ISO5167-3 2003]

13

Long radius nozzle [ISO5167-1 1991/ ISO5167-3 2003]

14

ASME FLOW NOZZLES [ASME MFC-3M 1989]

15

Venturi nozzle [ISO5167-1 1991/ ISO5167-3 2003]

16

Classical Venturi tube “as cast” convergent section [ISO5167-1 1991/ ISO5167-4 2003]

17

ASME Venturi Tubes With a rough Cast or Fabricated Convergent [ASME MFC-3M 1989]

18

Classical Venturi tube with a machined convergent section [ISO5167-1 1991/ ISO5167-4 2003]

19

ASME Venturi Tubes With a machined convergent section [ASME MFC-3M 1989]

20

Classical Venturi tube with a rough-welded sheet-iron convergent section [ISO5167-1 1991/ ISO5167-4 2003]