Yokogawa EJX930A User Manual

Page 69

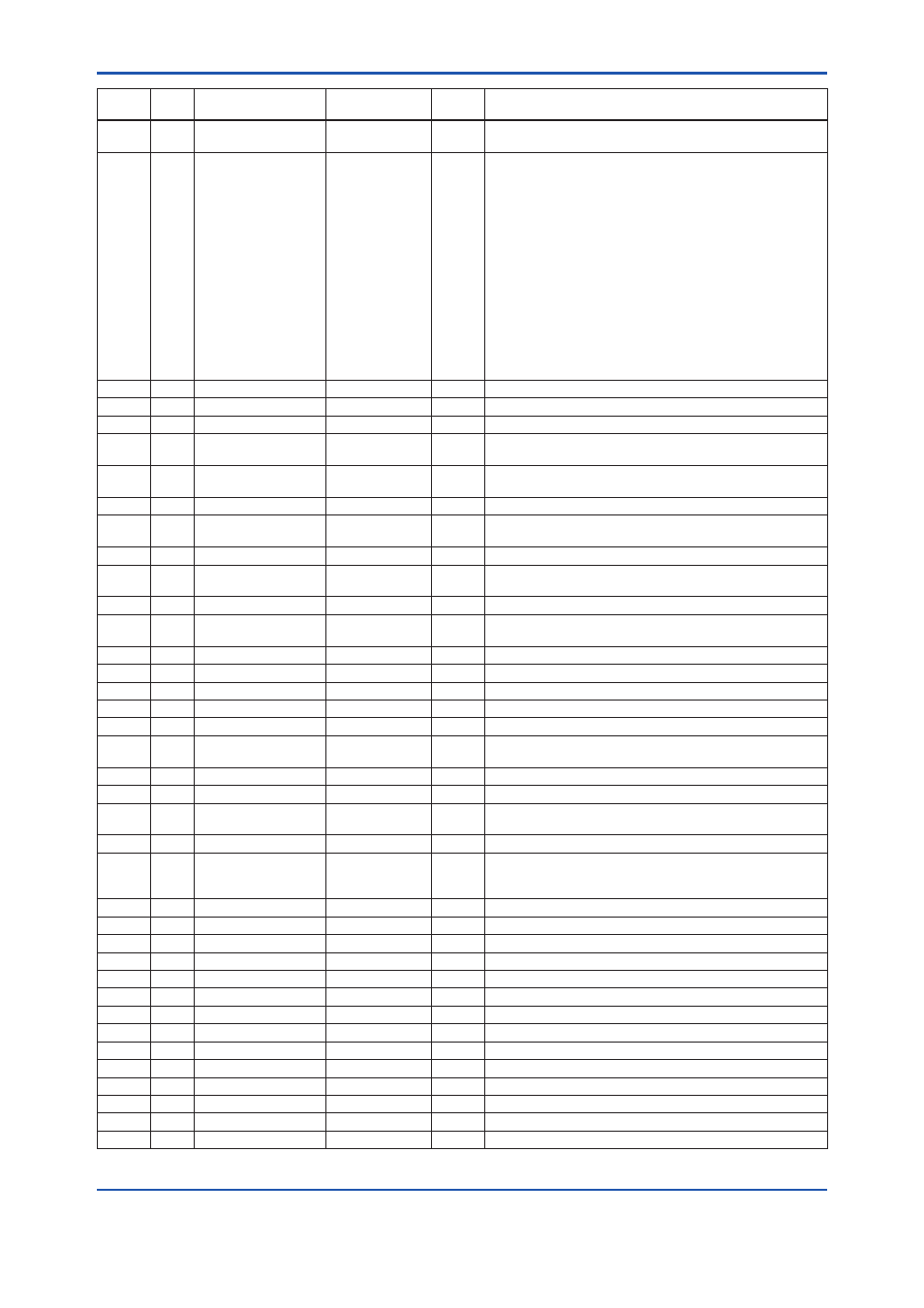

<9. Parameter Lists>

9-5

IM 01C25R03-01E

Relative

Index Index

Parameter Name

Factory Default

Write

Mode

Explanation

57

2057 FIXED_EXT_TEMP_

VALUE

20.0

O/S

Sets the external temperature fixed value.

58

2058 SIMULATE_MODE

0

AUTO

This is the switch for enabling simulation.

0=Simulation OFF

1=Differential pressure signal simulation ON

2=Static pressure signal simulation ON

3=Differential pressure signal + static pressure signal

simulation ON

4=External temperature signal simulation ON

5=Differential pressure signal + external temperature signal

simulation ON

6=Static pressure signal + external temperature signal

simulation ON

7=Differential pressure signal + static pressure signal +

external temperature signal simulation ON

15=Differential pressure signal + static pressure signal +

external temperature signal (without damping processing)

simulation ON

59

2059 SIMULATE_DPRESS 0

AUTO

Sets the differential pressure value and status for simulation.

60

2060 SIMULATE_SPRESS 0

AUTO

Sets the static pressure value and status for simulation.

61

2061 SIMULATE_ETEMP

0

AUTO

Sets the external temperature value and status for simulation.

62

2062 EXT_TEMP_

SENSOR_SN

space

AUTO

This parameter is for recording the serial No. of the external

temperature sensor.

63

2063 CLEAR_CAL

0

O/S

Reset zero and span adjustment to factory calibrated values for

pressure, static pressure, external temperature and or all.

64

2064 CAP_TEMP_VAL

—

Measured capsule temperature value and status.

65

2065 CAP_TEMP_RANGE -50.0 to 130.0°C

—

High and low range limit values, engineering units, decimal

point place for capsule temperature.

66

2066 AMP_TEMP_VAL

—

Measured Amplifier temperature value and status.

67

2067 AMP_TEMP_RANGE -50.0 to 95.0°C

—

High and low range limit values, engineering units, decimal

point place for Amplifier temperature.

68

2068 MODEL

Model code

—

The model code.

69

2069 SPECIAL_ORDER_ID Special order

number

—

Identification number of special order.

70

2070 MANUFAC_DATE

0

O/S

Date of production

71

2071 CAP_GASKET_MTL

Depend on Specify O/S

Material of capsule gasket

72

2072 FLANGE_MTL

Depend on Specify O/S

Material of flange

73

2073 D_VENT_PLUG

Depend on Specify O/S

Material of drain or vent plug

74

2074 FLANGE_TYPE

Depend on Specify O/S

Flange type

75

2075 REM_SEAL_ISOL_

MTL

Depend on Specify O/S

Material of isolating diaphragms for remote seal

76

2076 FLANGE_SIZE

Depend on Specify O/S

Flange size

77

2077 REM_SEAL_NUM

Depend on Specify O/S

Number of remote seal

78

2078 REM_SEAL_FILL_

FLUID

Depend on Specify O/S

Types of fill fluid in remote seals.

79

2079 REM_SEAL_TYPE

Depend on Specify O/S

Types of remote seals

80

2080 ALARM_SUM

Alarm Enable

—

The current alert status, unacknowledged states, unreported

states, and disabled states of the alarms associated with the

function block.

81

2081 AUTO_RECOVERY

1 (ON)

O/S

Permission of auto recovery from sensor errors.

82

2082 MS_CODE

Null

—

Model suffix and codes.

83

2083 DIAG_MODE

0 (stop)

AUTO

Used for ILBD. Refer to A8.2.12

84

2084 DIAG_PERIOD

180

AUTO

Used for ILBD. Refer to A8.2.12

85

2085 DIAG_PRI

1

AUTO

Used for ILBD and Heat Trace Monitoring. Refer to A8.2.12

86

2086 DIAG_ERR

—

Used for ILBD and Heat Trace Monitoring. Refer to A8.2.12

87

2087 DIAG_H_ALM

—

Used for ILBD and Heat Trace Monitoring. Refer to A8.2.12

88

2088 DIAG_L_ALM

—

Used for ILBD and Heat Trace Monitoring. Refer to A8.2.12

89

2089 DIAG_OPTION

0

AUTO

Used for ILBD and Heat Trace Monitoring. Refer to A8.2.12

90

2090 REF_LIM_ FDPMIN

7.00E-10

AUTO

Used for ILBD. Refer to A8.2.12

91

2091 REF_LIM_ FSPMIN

1.00E-10

AUTO

Used for ILBD. Refer to A8.2.12

92

2092 REF_LIM_BLKFMAX

0.5

AUTO

Used for ILBD. Refer to A8.2.12

93

2093 COMP_FLAG

0 (Compensation) AUTO

Used for ILBD. Refer to A8.2.12

94

2094 DIAG_LIM

(Note)

AUTO

Used for ILBD. Refer to A8.2.12