3 functions relating to differential pressure, Functions relating to differential pressure -3 – Yokogawa EJX930A User Manual

Page 42

<6. Explanation of Basic Items>

6-3

IM 01C25R03-01E

6.3.3 Functions Relating to Differential

Pressure

Reference to differential pressure value:

By accessing PRIMARY_VALUE, it is possible to

refer to the differential pressure value and status.

The update period of this value is 200 mseconds.

The pressure unit is selected by XD_SCALE.

unit of the AI block, in which PRIMARY_VALUE is

selected. The status is normally Good-Non Specific.

However, in the case of a sensor failure or out of

measurement range, it turns to Bad or Uncertain.

For details, refer to Table 8.9.

Setting of signal damping for differential

pressure:

When the differential pressure signal fluctuates

greatly, the fluctuation can be reduced by increasing

the time constant for signal damping. PRIMARY_

VALUE_FTIME is the parameter for setting the

signal damping for differential pressure. The unit of

signal damping is second.

Determination of the range limit of differential

pressure signal:

When the differential pressure signal deviates more

than 10% from the capsule measurement range

shown in PRIMARY_VALUE_RANGE, set the

status of PRIMARY_VALUE to Uncertain-Sensor

Conversion not Accurate.

Adjustment of pressure/differential pressure

signal:

EJX multivariable transmitter have been accurately

adjusted according to the specifications at factory

setting. Minimal errors can occur due to the

environment where the transmitter is installed and

the mounting position. To fine-tune any errors,

three zero/span adjustment functions can be used:

automatic and manual zero/span adjustment

by communication terminals, and zero-point

adjustment by means of the external adjustment

screw on the transmitter.

Automatic adjustment

The value of the pressure exerted on the point

where the adjustment is to be made is assigned

to parameters (CAL_POINT_LO, CAL_POINT_

HI). After this assignment is set, the amount of

adjustment is calculated by the transmitter and

automatically updated.

Manual adjustment

From the exerted pressure and the output of the

transmitter, calculate the amount of zero/span

adjustment manually, and assign the calculated

value to parameters (CAL_DEVIATION_LO,

CAL_DEVIATION_HI).

Zero-point adjustment by the external screw.

With pressure being exerted on the point where

the adjustment is to be made, zero adjustment

needs to be performed. To do this, adjust the

calculated value by turning the external Zero-point

adjustment screw, so that it agrees with the actual

input pressure (true value). The output value

increases when the screw is rotated to the right. It

decreases when the screw is rotated to the left. The

adjustment width is small when the rotation speed

is low and large when fast.

When performing zero-point adjustment by the

external screw, EXTERNAL_ZERO_TRIM needs to

be set to “Enable.”

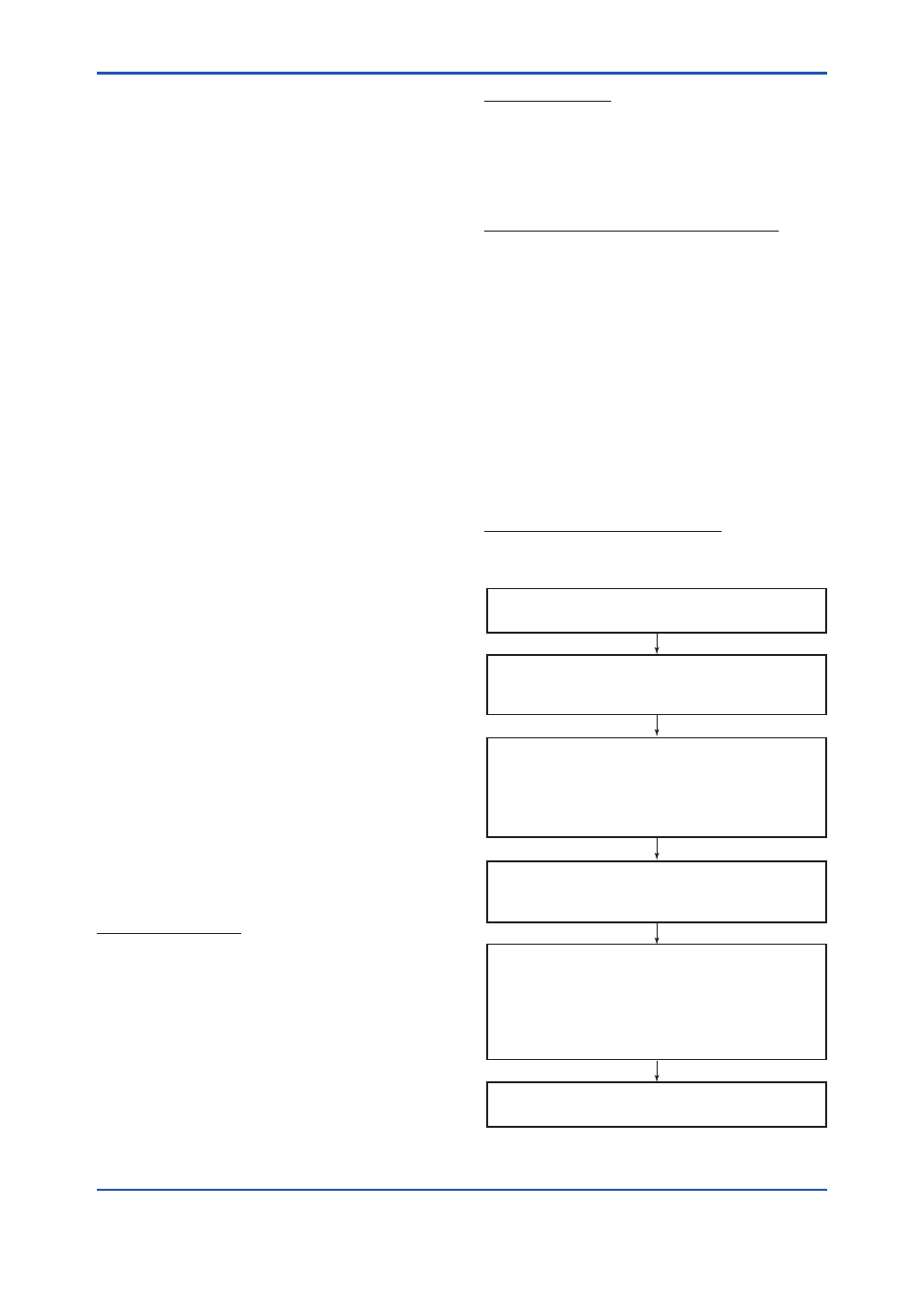

Procedure for automatic adjustment

The procedure for automatic adjustment is as

follows:

F0603.ai

(1) Change the Block mode

Set MODE_BLK to O/S.

(2) Enter zero% pressure

Apply the actual zero% pressure to EJX multivariable

transmitter.

(6) Change the operation mode

Set MODE_BLK to AUTO for normal operation.

(3) Perform zero adjustment

When the value of the applied pressure is written to

CAL_POINT_LO, EJX calculates the amount of

adjustment for zero adjustment. The calculated amount

of adjustment is incorporated into CAL_DEVIATION_LO.

(5) Performance of span adjustment

When the value of the applied pressure is written to

CAL_POINT_HI, EJX multivariable transmitter calculates

the amount of adjustment for span adjustment. The

calculated amount of adjustment is incorporated into

CAL_DEVIATION_HI.

(4) Input pressure for span adjustment

For span adjustment, apply the actual 100% pressure to

EJX multivariable transmitter.