IAI America LSA-S10SS User Manual

Page 55

6. Maintenance and Inspection

49

6.6 Procedures for Replacement and Adjustment of Stainless Steel

Sheet

Described below explains how to replace and adjust the stainless steel sheet.

Those parts such as screws taken off for replacement work are necessary when assembling the

product back. It is recommended to prepare a storage box in advance to starting the work, so the

taken off parts can be kept in it.

[Required Items]

• Replacement stainless sheet

• Hex wrench set

• Scale

• Box-end wrench (7mm)

• Adhesive tape

• Oil-based marker

• Tension gauge (having two forked hooks)

[Notes]

(1) Stainless sheet tension

Improper tension of the stainless sheet can promote deterioration and wear of the sheet.

If the stainless sheet is too taut and the clearance from the slider cover becomes exceeds

1mm, the stainless sheet may undergo fatigue failure.

On the other hand, excessive slacks cause the stainless sheet to contact the back of the slider

cover.

(2) Checking the clearance between the stainless sheet and the back of the slider cover

The stainless sheet is replaced without removing the slider cover.

Therefore, the clearance between the stainless sheet and the back of the slider cover cannot

be measured or checked directly.

The stainless sheet must be tensioned so that this clearance becomes 1mm.

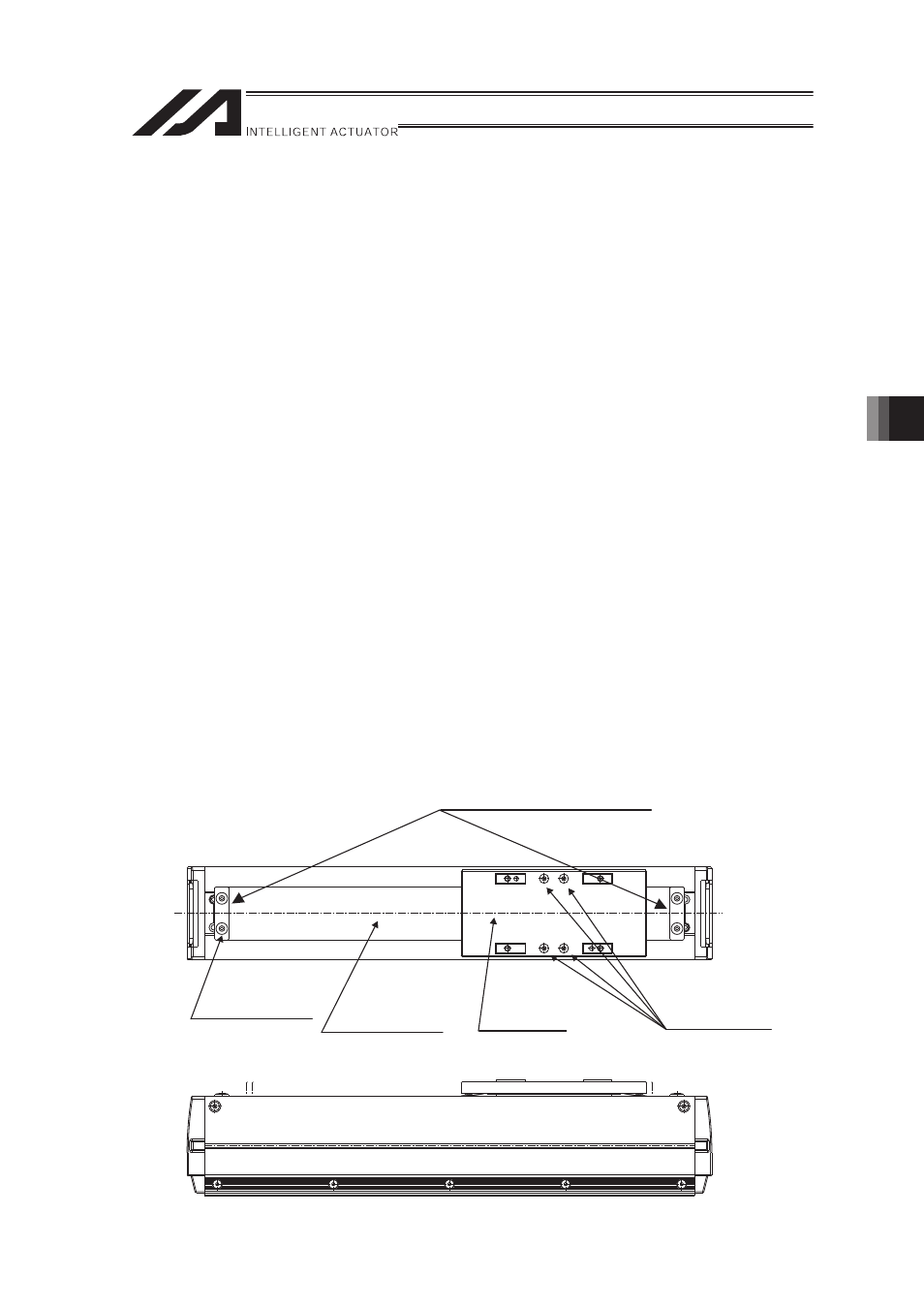

[Name of each part]

The figure below shows the actuator with its right and left covers removed to expose the stainless�

sheet retainer plates.

Stainless sheet retainer plates

Stainless sheet

retainer screws

Stainless sheet

Slider cover

Slider cover

affixing screws