5 adding grease – IAI America SSPA User Manual

Page 75

12. Maintenance/Inspection

67

12.5 Adding Grease

12.5.1

Applicable Grease

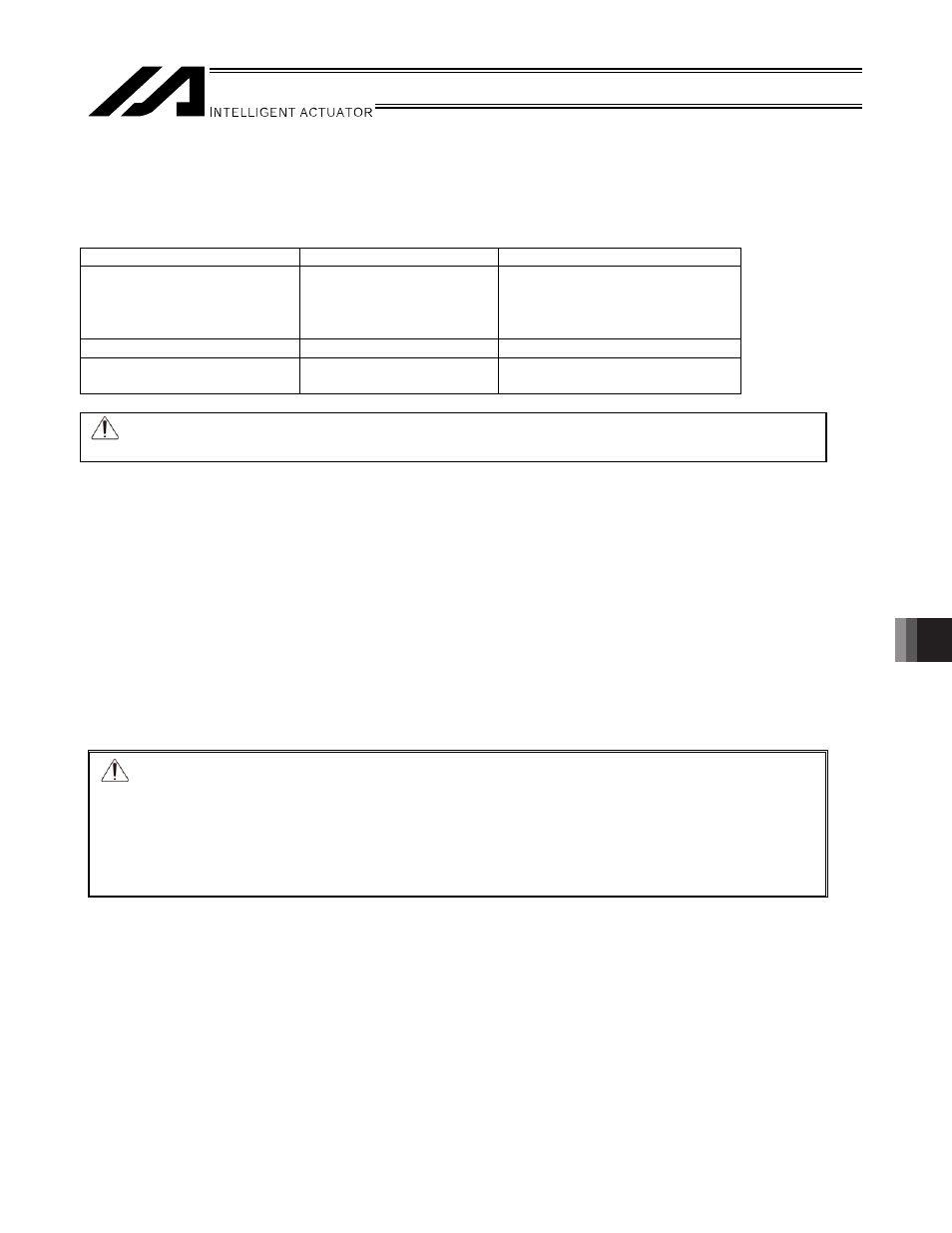

The following blends of grease are charged before shipment from IAI.

Type

Parts

Factor-set grease

ISB, ISPB

SXM/SXL

MXM/MXL/MXMX

LXM/LXL/LXMX/LXUWX

Guide, ball screw

Daphne Eponex Grease No. 2

SSPA

Guide, ball screw

Daphne Eponex Grease No. 2

ISB, ISPB

LXM/LXMX/LXUWX

Intermediate support

Multemp LRL No. 3

Warning: Never use fluorine grease. Fluorine grease will chemically react with lithium grease and

damage the machine.

12.5.2

Grease Application Method

(1) Adding grease to the guide and ball screw

A grease nipple is provided on the side of the slider. Add grease to the guide and ball screw through here.

The grease nipple on the right facing from the motor is to add grease to the guide and ball screw on the right

side.

The grease nipple on the left facing from the motor is to add grease to the guide and ball screw on the left.

(Grease can be added to the ball screw from either side of the grease nipples.)

[1] Apply grease from the left or right grease nipple three to four times using a grease gun.

[2] Move the slider several times by hand.

[3] Wipe off any excess grease.

Caution: y Charging too much grease may increase the agitation resistance and cause the ball

screw to generate heat easily or allow excess grease on the ball screw to scatter

around and dirty the surroundings as the screw turns. Be sure to wipe off excess

grease.

y

It is difficult to move actuators of short leads by hand. With these actuators, do not try to

move the actuator by force, but connect a controller and move the actuator by jog

operation.