IAI America SSPA User Manual

Page 24

2. Specification

16

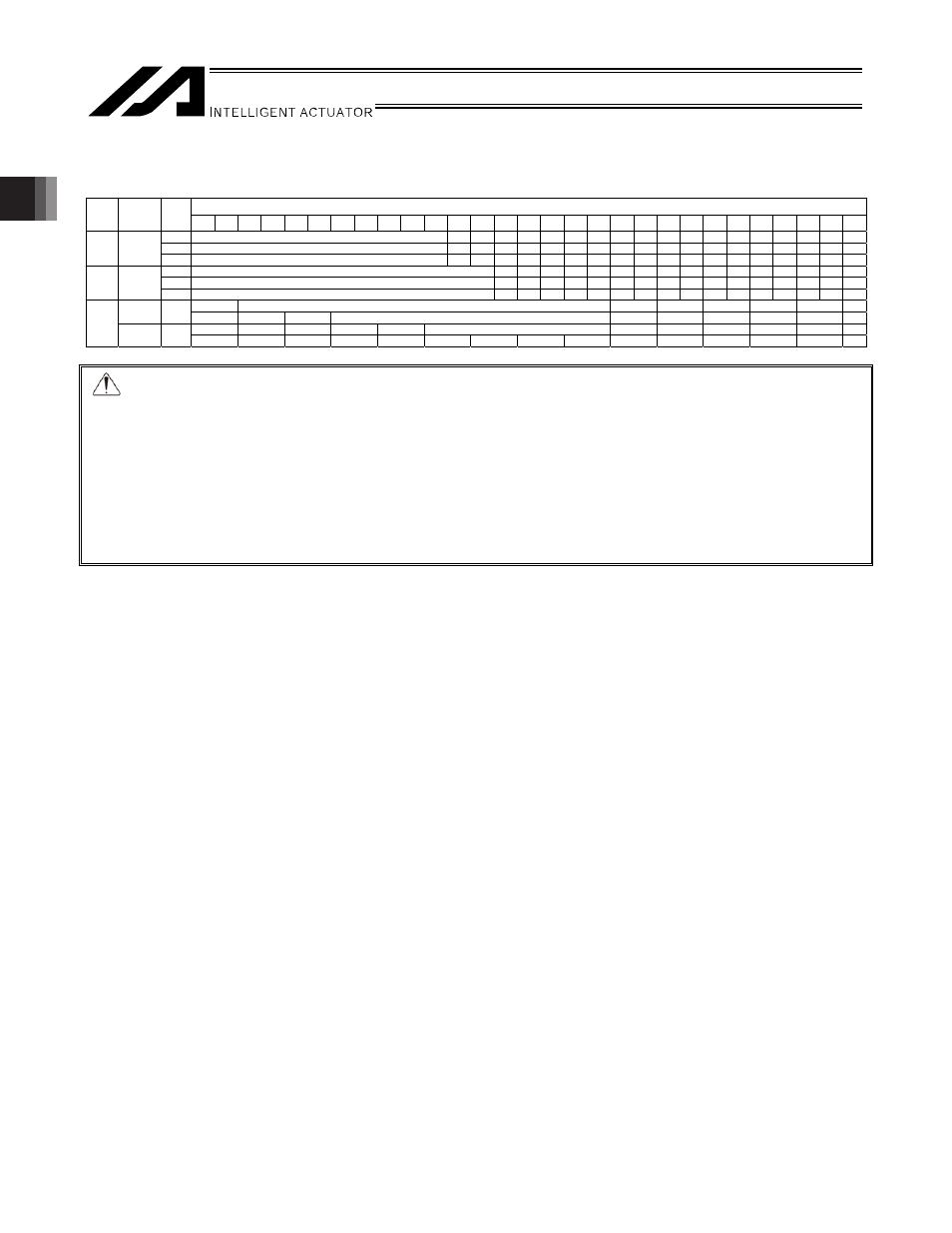

(2) SSPA

Stroke and maximum speed (or speed to reach) limits (Unit: mm/s)

Stroke [mm]

Size

Motor

capacity

[W]

Lead

[mm] 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

10

600

560 490 440 390 350 320 290 260 240 220 -

-

-

-

-

-

-

-

20

1200

1120 990 880 780 710 640 580 530 480 440 -

-

-

-

-

-

-

-

SXM

200

30

1800

1680 1480 1320 1180 1060 960 870 790 730 670 -

-

-

-

-

-

-

-

10

600

530 480 430 390 360 330 300 280 250 240 220 200

-

-

-

-

20

1200

1070 960 870 790 720 660 600 560 510 480 440 410

-

-

-

-

MXM

400

40

2400

2150 1930 1740 1580 1440 1320 1210 1120 1030 960 890 830

-

-

-

-

1080

1250

1160

970

830

720

620

550

750

25

620

880

1080

1250

1160

970

830

720

620

550

1080

1530

1870

2160

2420

2500

2320

1950

1660

1440

1250 1100

LXM

750

50

620

880

1080

1250

1400

1530

1650

1770

1870

1970

1950

1660

1440

1250 1100

Caution: (1) Do not set speeds and accelerations/decelerations equal to or greater than the respective

ratings. Doing so may result in vibration, failure or shorter life.

(2) In the case of interpolated operation of two or more orthogonal axes, make sure the command

values (settings) of speed and acceleration/deceleration do not exceed the smallest values of

all speeds and accelerations/decelerations of the applicable axes.

Even if any speed or acceleration/deceleration is set that exceeds the smallest speed or

acceleration/deceleration among all applicable axes, the actual speed or

acceleration/deceleration will be clamped to the smallest speed or acceleration/deceleration.

(3) If any acceleration/deceleration equal to or greater than the rated acceleration/deceleration is

set, a creep phenomenon or slipped coupling may occur.