3 installing the load on the slider – IAI America SSPA User Manual

Page 45

6. Installation

37

6.3 Installing the Load on the Slider

x

The slider has threaded holes, so affix the load using these holes. The affixing method shall conform to the

method for installing the actuator.

x

Similarly when the slider is affixed and actuator is moved, install the slider using these threaded holes on the

slider.

x

The slider has two reamed holes. If repeatability is required after removal/re-installation, use positioning pins.

If squareness is required, use one positioning pin and make installation adjustment.

x

After removal/re-installation, repeatability can also be ensured by pushing the reference surface on the side of

the base.

x

Use high-tension bolts conforming to ISO 10.9 or higher.

x

When the threaded holes are used, determine the required thread length as specified below:

x

ISB, ISPB

Depth of threaded hole > Thread engagement length > Nominal thread size x 1.8

x

SSPA

Depth of threaded hole > Thread engagement length > Nominal thread size

z

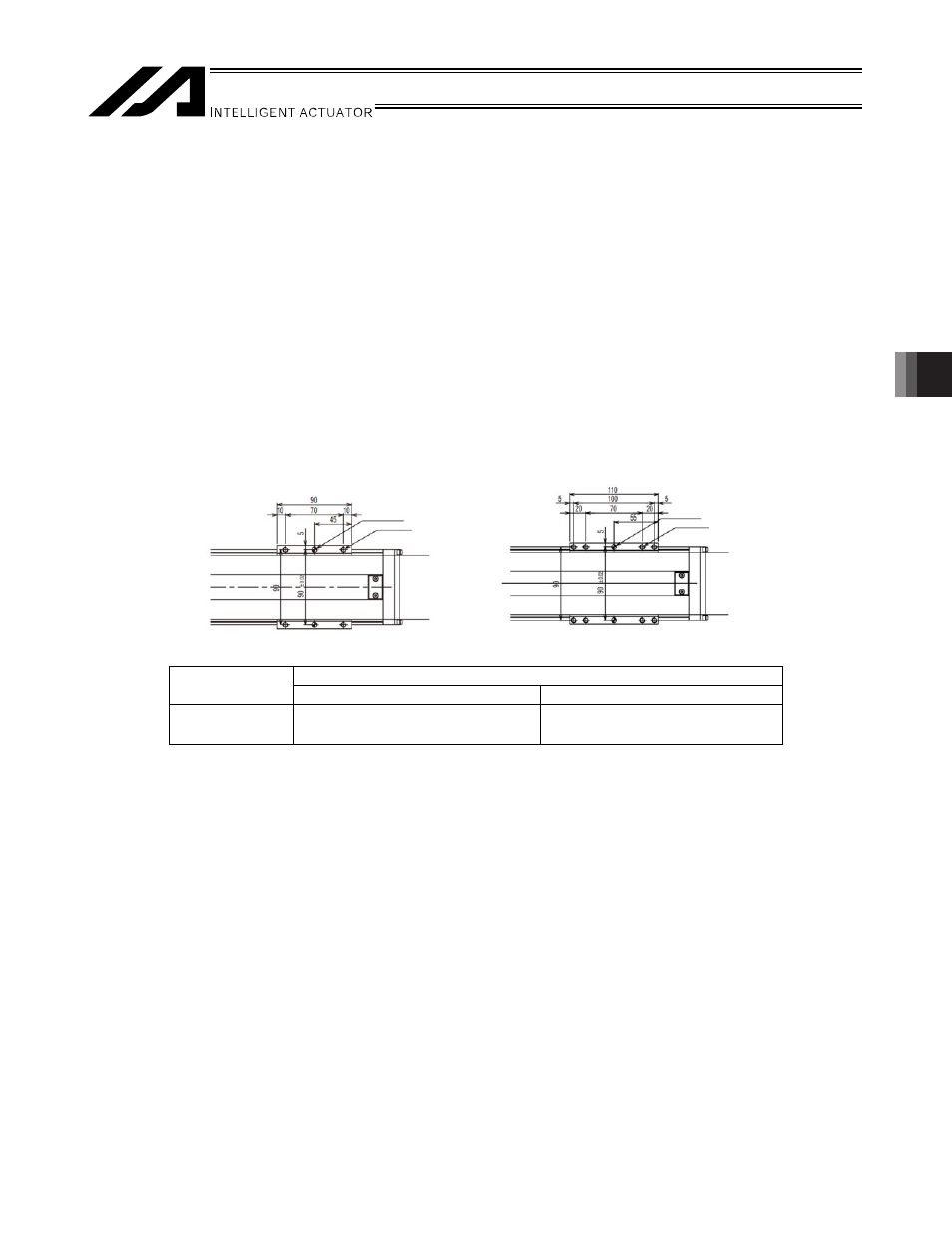

ISB, ISPB: Small type SXM/SXL

SXM slider

SXL slider

Tightening torque

Installation bolt

Bolt seating surface is steel

Bolt seating surface is aluminum

M6

12.3 Nxm

5.4 Nxm

(Note) When using positioning holes, use pins with an engagement tolerance of h7 or equivalent.

2-6H7, depth 10

4-M6 depth 18

2-6H7, depth 10

8-M6 depth 18