2 installing the actuator – IAI America SSPA User Manual

Page 39

6. Installation

31

6.2 Installing the Actuator

6.2.1

Installation Method

x

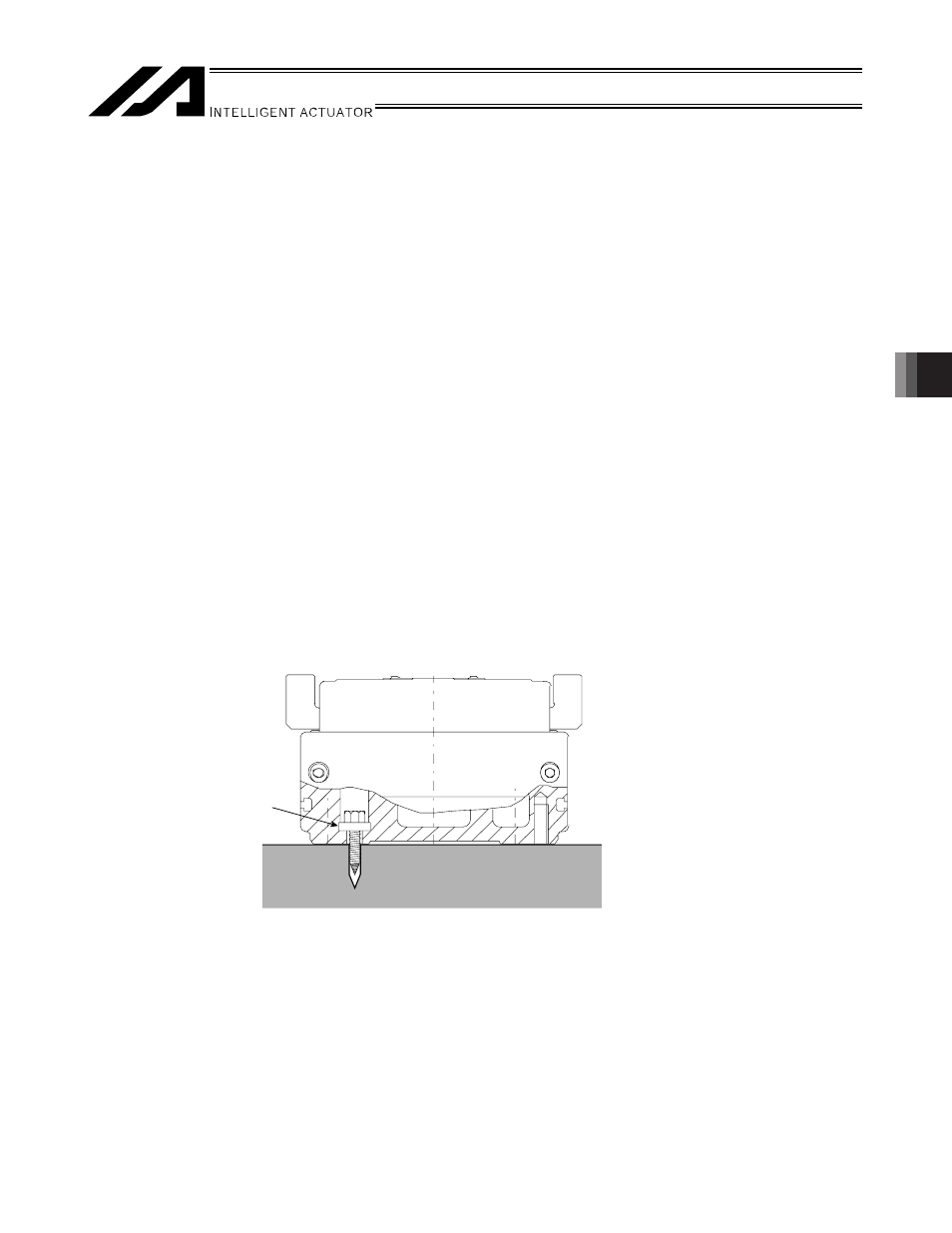

Use the threaded holes on the back of the base to install the actuator. Actuators of intermediate support type

(MXMX/LXMX/LXUWX) don’t have threaded holes. Actuators have through holes, in addition to the

aforementioned threaded holes, so that the actuator can be installed using hexagonal socket-head bolts that

are guided through from the actuator side. If the throw holes are used, remove the screw cover and install

them from the top surface.

x

Actuators of intermediate support type (MXMX/LXMX/LXUWX) are installed in the same way as the

corresponding actuators without intermediate support. However, be careful not to remove or get caught by the

wire rope for the intermediate support during installation.

x

When positioning pins are used, use pins with an engagement tolerance of h7 or equivalent.

x

Positioning can be performed by pushing the reference surface on the side of the base. [Refer to 6.2.2,

"Precision of the Installation Surface."]

x

Use high-tension bolts conforming to ISO 10.9 or higher.

x

When the threaded holes are used, determine the required thread length as specified below:

x

ISB, ISPB

Depth of threaded hole > Thread engagement length > Nominal thread size x 1.8

x

SSPA

Depth of threaded hole > Thread engagement length > Nominal thread size

x

If the through holes are used for installation, provide the following effective engagement length, whichever is

applicable, for the female thread:

x

If the female thread is made of steel, same as the nominal diameter

x

If the female thread is made of aluminum, 1.8 times of nominal diameter

x

If the bolt seating surface is aluminum, or the through holes are used, also use high-tension bolts with

dedicated washers. Failure to do so may cause the seating surface to buckle.

Dedicated washer for

high-tension bolt (supplied)