IAI America RCS2-A6R User Manual

Page 57

4. Maintenance Inspection

51

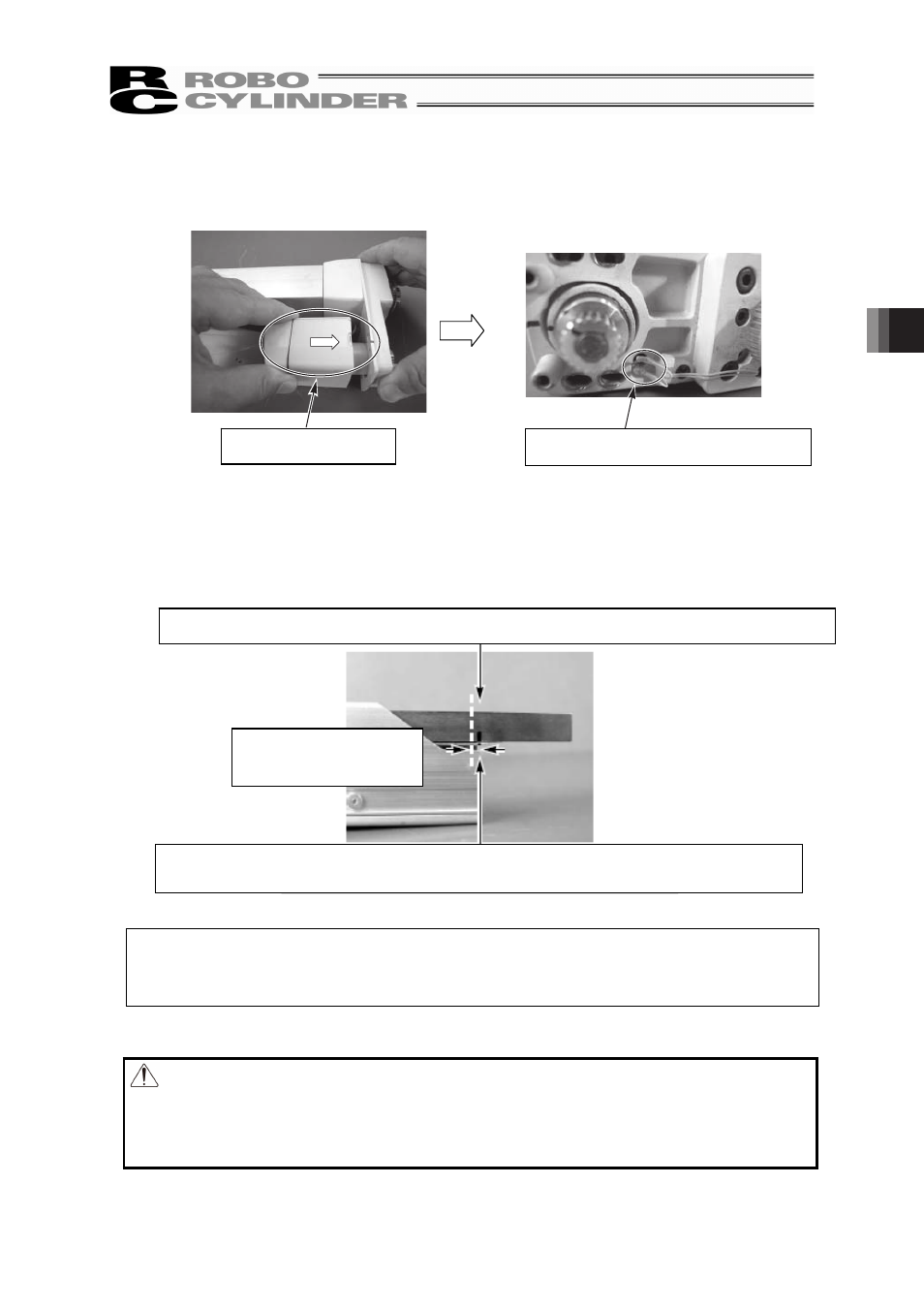

(4) Install the replacement motor unit. If the actuator has a brake, solder and connect the brake

cable. Cover the soldered portion of the cable with a vinyl tube and then temporarily secure it

with the motor-unit affixing bolts.

�

�

�

�

�

�

�

�

(5) Move the slider to a position where Z phase turns ON.

This corresponds to a position where the rod projects A4R is 0.6mm, A5R and A6R is 0.7mm

from the mechanical end.

Apply countermarks in this position.

�

�

�

If the actuator has a brake, connect this machine to the controller and pull out the slider to the

stroke end after the brake has been released with the brake release switch. Then, turn OFF

the controller power for safety.

�

�

�

Warning: If the actuator is installed vertically, move it after turning on the controller

power and forcibly releasing the brake. At this time, beware of danger as the

actuator may drop suddenly.

Always provide a support to brace the actuator hand to prevent sudden drop,

so as not to pinch fingers or damage the load.

�

Cause the

slider to project A4R is 0.6mm, A5R and A6R is 0.7mm from the mechanical end.

Apply countermarks once the

slider has projected A4R is 0.6mm, A5R and A6R is 0.7mm

from the mechanical end.

A4R

:

0.6mm

A5R and A6R

:

0.7mm

Solder and connect the brake cable.

Replacement motor