IAI America RCS2-A6R User Manual

Page 35

2. Installation

29

2.3.2 Installation of Main Unit

The surface to mount the main unit should be a machined surface or a plane that possesses an

equivalent accuracy and the flatness should be within 0.05mm/m.

Install the main body as follows:

About Tightening Screws

�

Use a hex socket head cap bolt for the attachment to the base.

�

It is recommended to use high-tensile bolts with ISO-10.9 or more.

�

Make sure to have the effective length of bolt engagement described below or more for the

tightening of a bolt and a female screw.

When female screw is on steel � Thread length same as nominal diameter

When female screw is on aluminum � Thread length 2 times longer them nominal diameter

Caution: Pay special attention when selecting the bolt length. In case that an inappropriate

length of a bolt is applied, it may cause a drop in the operation accuracy or an

unexpected accident due to a damage, insufficient strength of actuator attachment

or an interference with the operating area.

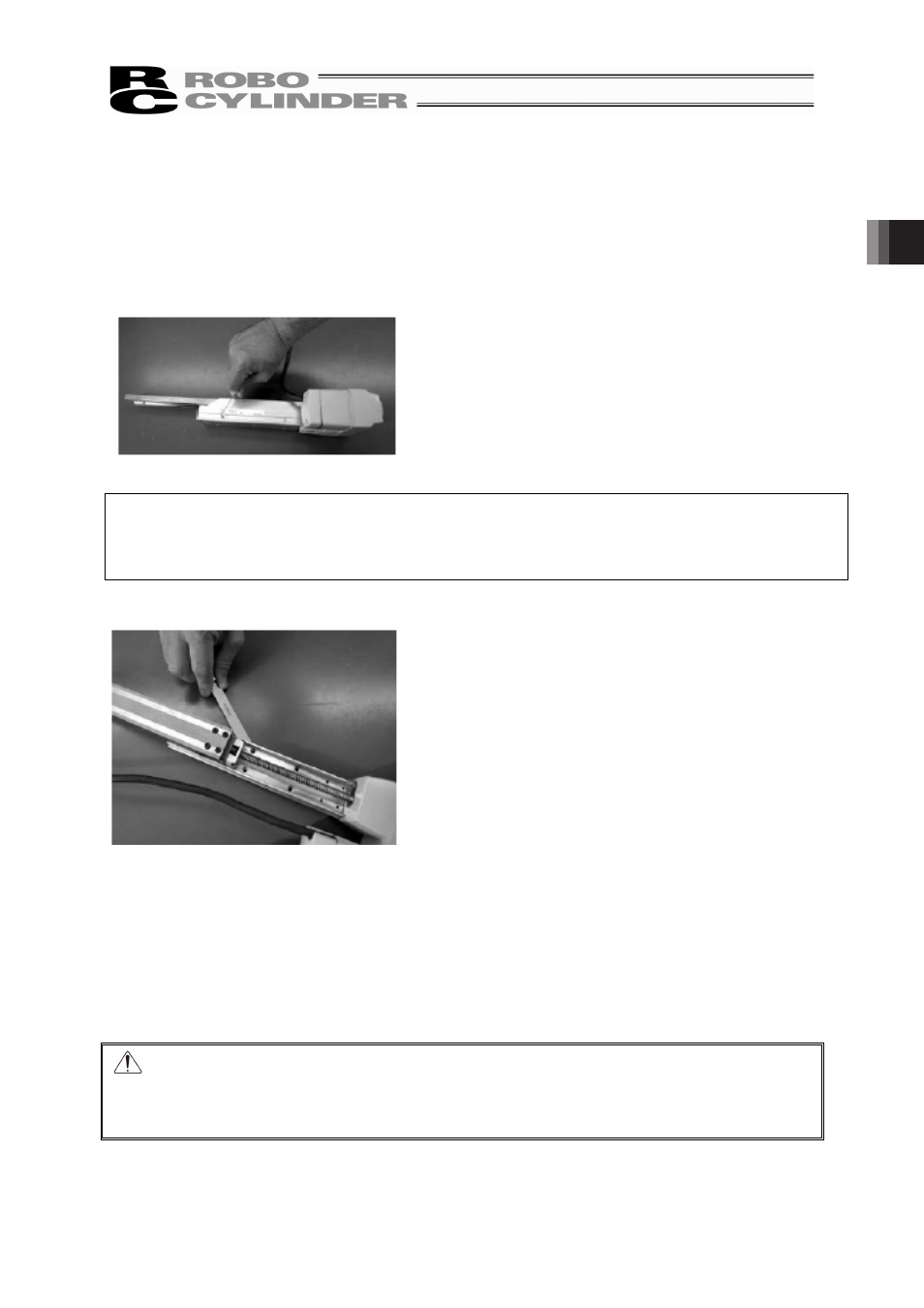

Pull out the slider to the stroke end. Remove four screw

cover mounting screws with an Allen wrench of 1.5mm

across flats to remove the screw cover.

If the actuator has a brake, connect this machine to the controller and pull out the slider to the stroke

end after the brake has been released with the brake release switch. Then, turn OFF the controller

power for safety.

Check to see that a 0.1mm thick gauge cannot be inserted

at the mounting holes while this machine is left standing

on the mounting surface.