Troubleshooting guide (cont.) – Ransburg Evolver 303 Dual Purge Solvent Robotic Applicator A12374-XXX User Manual

Page 56

51

Evolver 303 Dual Purge Robotic Atomizers - Maintenance

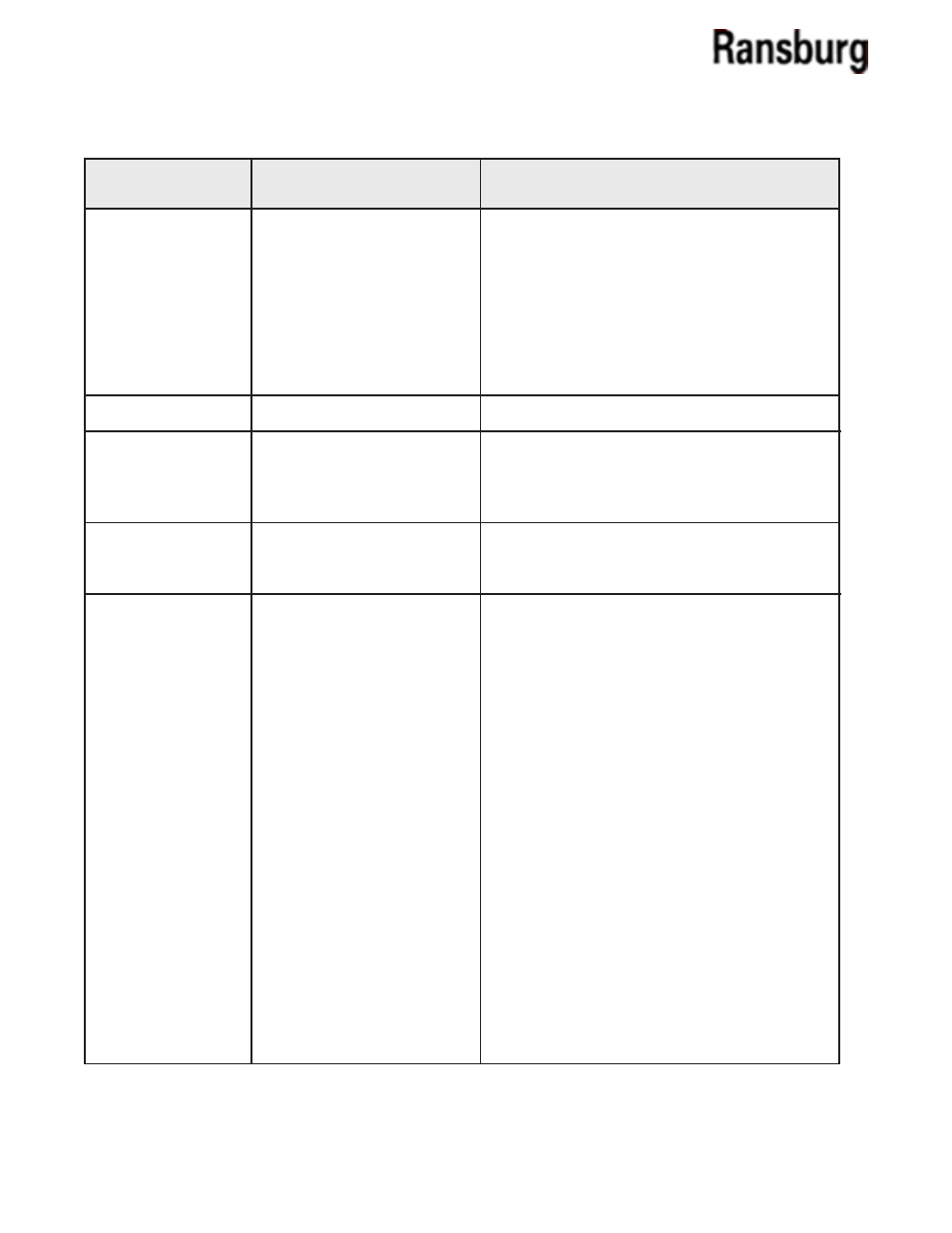

TROUBLESHOOTING GUIDE (Cont.)

General Problem

Possible Causes

Corrective Action

1. Insufficient back pressure

to fluid regulator

2. Fluid regulator does not

control flow (system)

3. Diaphragm stretched from

excessive air pressure

4. Ruptured diaphragm

5. Inconsistent air pilot supply

1. Ruptured Diaphragm

1. Damaged o-ring(s) on outer

diameter of valve body

2. Damaged or worn needle

seals inside valve assembly

1. Diaphragm (screws) loose

2. Ruptured diaphragm

1. High current draw

2. Loss of low voltage cable

connection between robot

and mounting plates.

3. Improper limiting current

and voltage settings.

4. Applicator grounding out

(usually indicated by high

current draw or by MicroPak

over-current fault light)

1. Replace fluid tube with the next smaller inner

diameter size.

2. Disassemble fluid regulator and inspect for

failed components (system).

3. Rebuild regulator.

4. Rebuild regulator.

5. Check air source.

1. Replace regulator diaphragm.

1. Replace o-ring.

2. Inspect tubing coil for scratches and replace if

damaged.

1. Replace o-ring(s).

2. Replace valve assembly.

1. a. Paint resistivity to be .1M

Ω to ∞.

b. Replace coiled fluid line.

2. Remove applicator and inspect low voltage

connections on both plates. Verify alignment

marks between connectors and plates and

verify that connector face is flush with plate.

Verify that set screws are secur, but not too

tight, as this will prevent the spring loaded pins

on the robot plate from extending and making

contact.

3. To readjust settings, refer to "MicroPak"

operating manual.

4 a. Clean atomizer externally with non-polar sol-

vent.

b. Check the atomizer for internal fluid leaks.

c. Check for fluid leaks at quick disconnect

mounting (between bell plate and robot

plate).

d. Check for internal arcing (usually indicated

by internal sparking sounds).

e. Make sure cascade low voltage connection

is properly shielded.

Uncontrollable Fluid

Flow

Paint Sputtering

Fluid Leakage

Around Fluid Valve

Paint Leakage

(Regulator)

Low or No High Volt-

age

(Continued On Next Page)

AA-08-01.1