Low voltage cable installations, See figures 6, 7, and 8), Table 1 - spacer plates – Ransburg Evolver 303 Dual Purge Solvent Robotic Applicator A12374-XXX User Manual

Page 22

17

Evolver 303 Dual Purge Robotic Atomizers - Installation

Robot Spacer Plate

The robot spacer plate is included with the robot

manifold assembly to increase life of the tubing

bundle. The extra spacing it provides increases the

bend radius of the tubes and decreases the hose or

cable stress at the connector.

There is only one way the spacer plate may be as-

sembled to the mounting plate. The spacer plate has

an alignment pin that may only engage in one hole

position in the robot mount plate. This provides the

final position to top dead center of the robot.

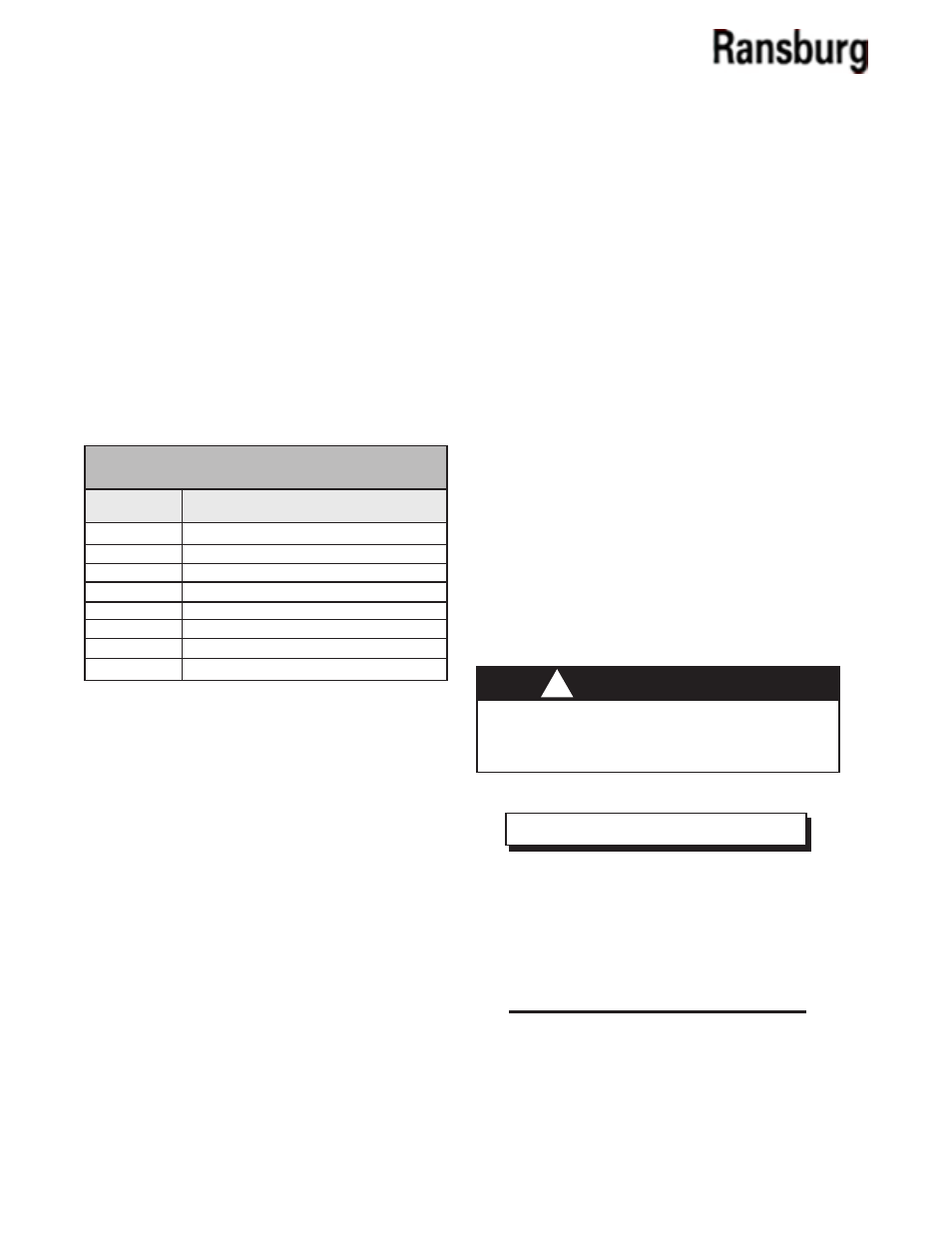

Six (6) robot spacer plates shown in Table 1 are avail-

able for this product.

LOW VOLTAGE CABLE

INSTALLATIONS

(See Figures 6, 7, and 8)

A low voltage cable is provided to send power to

the high voltage cascade in the applicator as well

as sending important information during operation

back to the MicroPak controls. One piece of the cable

is a permanent length of approximately

72-inches (1.8 meters) from the robot plate end. The

connecting cable can be ordered in various lengths

depending on the distance required to reach from

the robot arm to the MicroPak controller. The ends of

the cables have a male and female quick disconnect

end. This provides for a quick and easy removal of

the cable at the robot plate if servicing or replace-

ment is required.

It is important that the quick disconnect fitting be

secured to a good ground source. The A12241-XX

cable is supplied with a ground cable which can be

secured to the bulkhead connector and the other

end to a known ground source. The cable can also

be grounded by attaching the bulkhead connector

to a grounded bulkhead plate. The bulkhead plate

can be no more than 1/8-inch (3.18mm) in thickness.

The bracket should be made as in Figure 7 to hold

the connector from turning. To mate the connec-

tors, align the raised key section of the cable on the

applicator end with the key groove of the cable that

goes to the MicroPak. Push the male end into the

mating connector until an audible click is heard. Tug

on cable to ensure that it is locked in place. To remove

or disconnect the cable, pull back on the male con-

nector shell and pull cable back at the same time. To

remove this section from the robot plate, remove the

applicator. Locate the set screw holding the flanged

plastic 9 pin connector. Loosen with a 3/32" hex key

wrench. Pull the cable out from the robot plate end.

Install new cable in reverse direction, align the 9 pin

connector with the alignment mark on the robot

plate face and tighten set screw. Torque 5-10 lbs•in

(0.56-1.13 Nm).

>

Cable connector shell must be electrically

grounded. Electrical noise or other interference

may result.

W A R N I N G

!

>

With the exception of fluid, dump, and

bearing air/paint trigger, all other pilot and

air supply lines should be bulkheaded and

their diameters increased one nominal size.

For example: atomization air should be in-

creased to an 1/2" ID (8mm) from bulkhead

plate to the volume booster.

NOTE

79107-00

ABB 5400, 5002 Robots

78983-00

Fanuc P155, 145 Robots

79131-00

Fanuc P200/P-250 Robots

A10847-00

Adapter (Kawasaki-KE610L)

A10848-00

Adapter (Motoman-PX2850)

A10849-00

Adapter (Motoman-PX2900)

A10851-00

Adapter (B & M LZ2000)

A12036-00

Adapter (ABB 5400 Enhanced Wrist)

Part #

Description

TABLE 1 - SPACER PLATES

AA-08-01.1