Calibration standards – GF Signet 4150 Turbidimeter User Manual

Page 8

8

Signet 4150 Turbidimeter

The Calibration Standards Kit includes three cuvettes and three pre-mixed calibration standards which are certi¿ ed to be within the

stated accuracy tolerances.

• For 3-4150-3 and -4 (range 0-100 NTU): P/N 3822-4001 (code 159 001 585) Calibration Kit, Turbidity, 100, 10 & 0.02 NTU.

• For 3-4150-1, -2, -5 and -6 (range 0-1000 NTU): P/N 3822-4003 (code 159 001 586) Calibration Kit, Turbidity, 1000, 10 & 0.02 NTU.

• A Formazin stock solution kit is also available (P/N 3822-4002). Formazin is very unstable, so it is important to ensure that a fresh

stock suspension of Formazin is used to achieve the accuracy quoted for the instrument. The non-Formazin calibration standards are

much more stable than Formazin and have a shelf life of 12 months.

• If the application is limited to measurements below 10 NTU, such as potable water, a 2-point calibration may be performed using only

a 10 NTU and a 0.02 NTU standard.

• If the Signet 4150 Turbidimeter will be used over the entire range, a 3-point calibration is required.

• For best results, index new calibration standard cuvettes to the speci¿ c instrument before ¿ rst use.

• Calibration standards with values of 0.02 NTU and 1000 NTU are supplied in sealed glass cuvettes and are ready to use.

• Calibration standards with values of 10 NTU and 100 NTU are supplied in a 125 ml bottle and must be poured into the empty glass

cuvettes included in the Calibration Standards Kit. The 125 ml plastic bottle contains suf¿ cient calibration standard to perform the

calibration four times.

Calibration Standards

Calibration Tips

• Keep the measurement cell covered as much as possible during the calibration period.

• Replace the cuvette immediately after the calibration to prevent accelerated saturation of the desiccant.

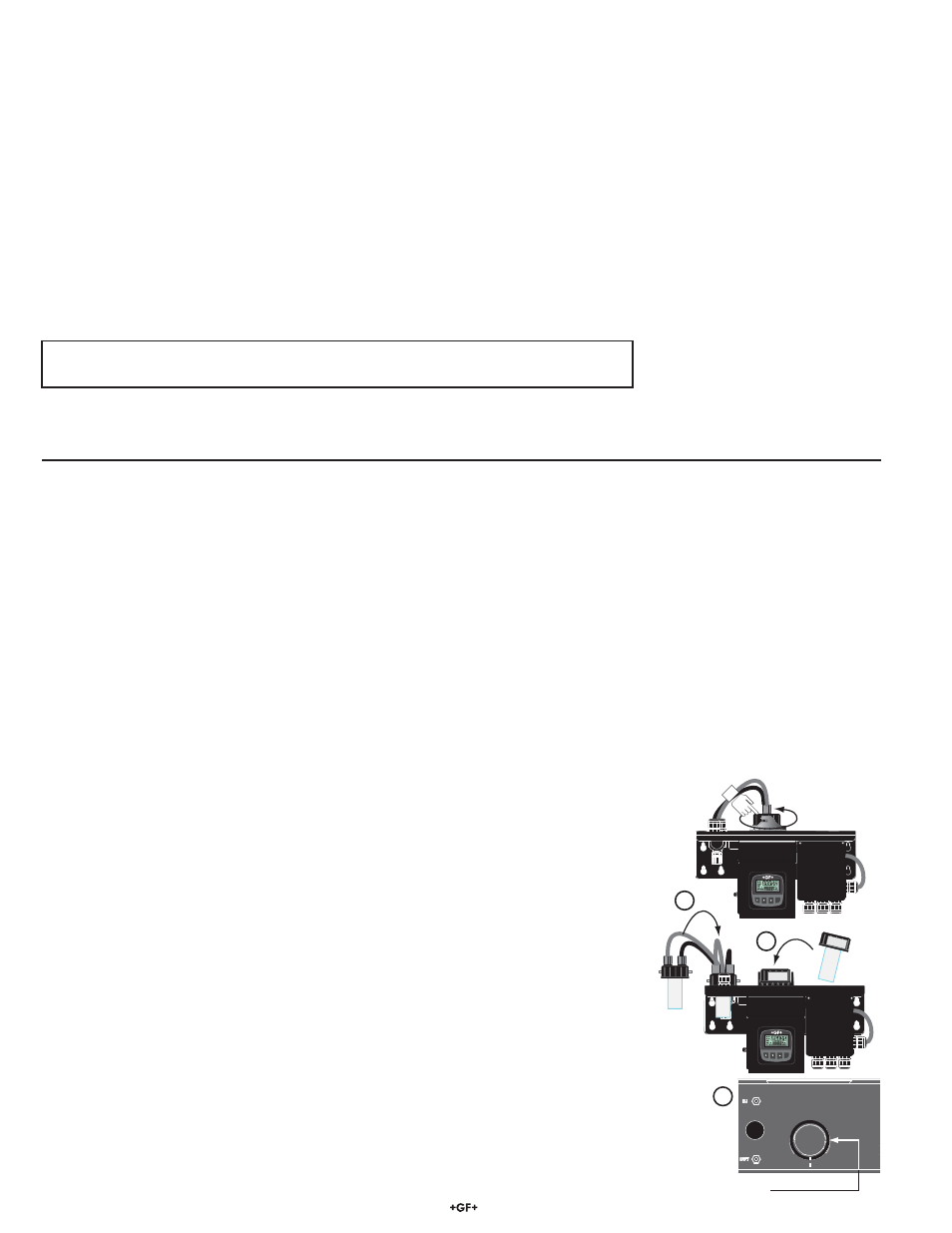

Indexing Calibration Standard Cuvettes

To achieve the greatest accuracy, and compensate for normal scratches and aberrations in cuvette

glass when calibrating, index new calibration standard cuvettes to the speci¿ c instrument before using

the ¿ rst time. For best results, use the indexing rings supplied with the calibration standard kits.

The following steps allow repeatable indexing of calibration standard cuvettes:

1. With the instrument in normal display mode, remove the measuring cuvette and place it in the

cuvette holder.

2. Insert the calibration standard cuvette into the measurement chamber of the 4150 Turbidimeter.

Allow a few minutes for the NTU/FNU reading to stabilize.

3. While slowly rotating the calibration standard cuvette inside the optical well one complete (360º)

revolution, observe the measured turbidity and locate the position of the cuvette having the

lowest reading.

4. With the calibration standard cuvette positioned at the location having the lowest turbidity

reading, install an indexing ring over the cuvette cap so that the pointer of the indexing ring

aligns with the white reference line on the 4150 Turbidimeter.

The calibration standard cuvette is now indexed and ready for use.

Perform this procedure with each calibration standard cuvette.

Cuvette Indexing Ring

Preparing 10 and 100 NTU Calibration Standards

The 10 and 100 NTU solution is supplied in a 125 ml bottle and must be poured into the empty cuvettes supplied. Prepare the 10 and

100 NTU solution using the same method outlined below.

1. Pour 5 ml of the 10 or 100 NTU calibration standard into the empty cuvette included in the Calibration Standards Kit.

2. Swirl the calibration standard to cover the entire internal surface of the cuvette and discard.

3. Fill the cuvette with 20 ml of the calibration standard and tighten cap to prevent contamination. Save the 125 ml plastic bottle with

the remaining calibration standard for future use.

4. Mark the cap of the cuvette with the initial pour date of the calibration standard.

5. Use the soft lint-free cloth supplied with the Calibration Standard Kit to clean the outside of the cuvette.

6. Index the calibration standard cuvette as described below.

The solution is now ready to perform a "Primary calibration". Once the "primary" calibration is performed the calibration kit can also

be used to verify that the 4150 is still accurate. Use either the 10 or 100 NTU cuvette to perform spot checks on the 4150 in between

primary calibrations.

NOTE: The 10 and 100 NTU solution degrades and becomes inaccurate after three months. It is important to discard the solution and

rinse the cuvettes with mild detergent and DI water prior to replacing the solution.

DO NOT USE a bottle brush to clean the cuvette, scratches to the internal surface will alter the optical quality of the glass.

IMPORTANT! Calibration does NOT remove OFFSET values.

ALWAYS turn the OFFSET function OFF (Options menu) before performing a full calibration

10 NTU

10 NTU

Signet Turbidimeter

ENTER

Signet Turbidimeter

ENTER

NOTE: When using the calibration standard cuvette in future or for multiple systems, always insert the cuvette

so that the pointer of the indexing ring aligns with the white reference line on the 4150 Turbidimeter. Slowly

rotate the calibration standard cuvette back and forth about 5° to locate the position of the cuvette having the

lowest reading.

4

2

1