GF Signet 4150 Turbidimeter User Manual

Page 21

21

Signet 4150 Turbidimeter

Troubleshooting

Signet 4150 Fault Detection

The Signet 4150 performs continuous diagnostic monitoring. There are three levels of fault detection: warnings, errors and failures.

Warning

A warning is simply a screen indication of a problem. The measurement is not interrupted and no alarms are activated.

• When the desiccant becomes saturated, a screen warning of DESC will appear.

Error

An error indicates a failure or a problem that usually can be corrected. These errors include:

• 4 to 20 mA loop open (MA)

• Bad calibration (CAL)

• Desiccant alarm activated and replacement required (DESC)

• Ultrasonic transducer is not making contact or the À ow through cuvette has been removed (CLN)

• Lamp out (LAMP)

The source lamps in the Signet 4150 are designed for long life. The IR lamp is rated for 10 years and the white light version is rated

for 7 years.

Replacing the lamp involves signi¿ cant disassembly and handling delicate components.

We recommend returning the unit to the factory for this service. If ¿ eld replacement is required, contact the factory for assistance.

If any of these conditions occurs, both relays will be set to the alarm state and the 4 to 20 mA output be held at the Error Level (ERLV)

selected in the Options Menu (if 4 to 20 mA is selected).

System FAIL Message

A failure is a system fault. This is NOT a problem that the operator can correct, and the unit must be returned to the factory for service.

If a failure occurs, the instrument will not function properly and will display the word FAIL on the lower row. Both alarm relays will be

activated and the 4 to 20 mA output will be held at the Error Level (ERLV) selected in the Options Menu (if 4 to 20 mA is selected).

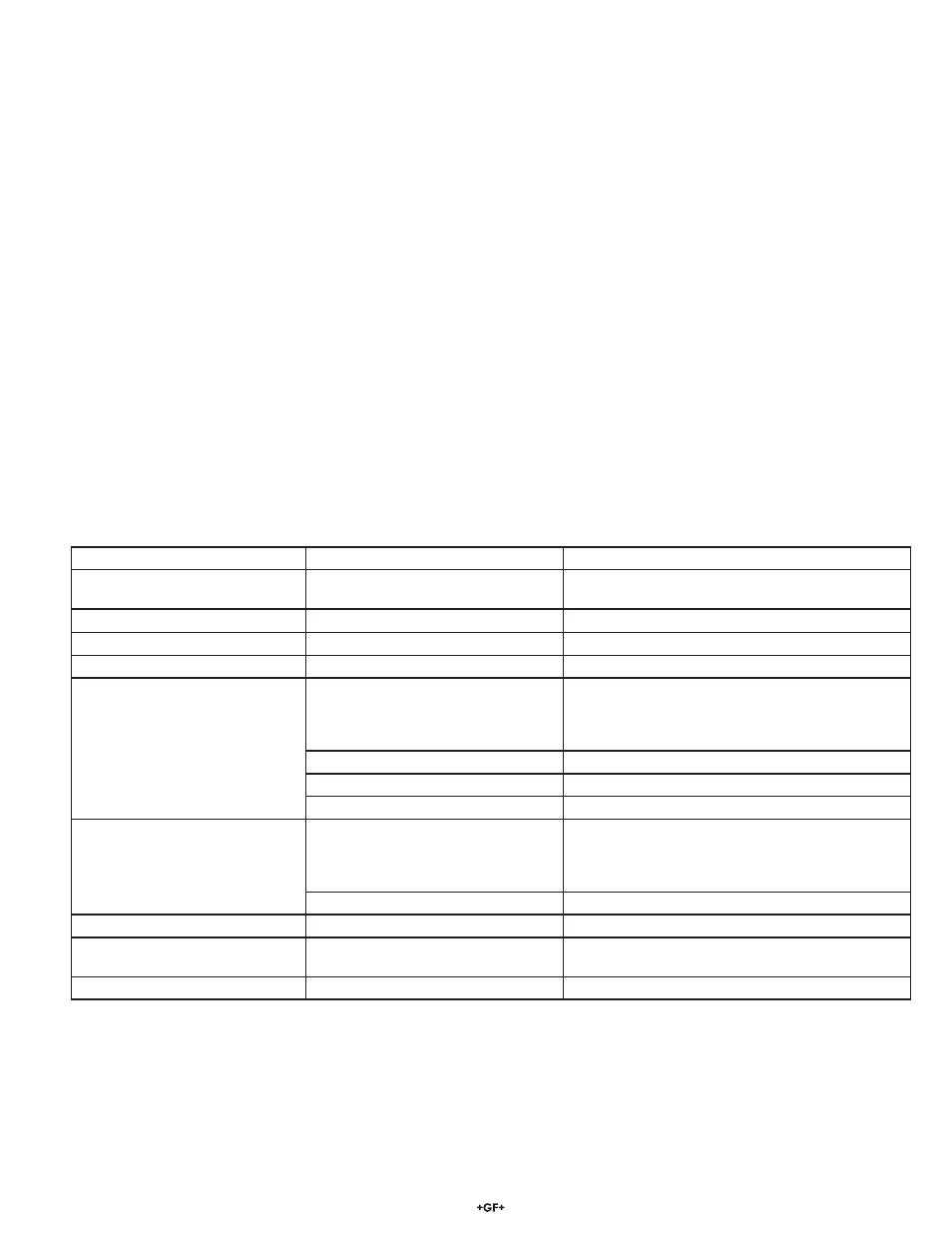

Symptom

Possible Cause

Solution

Lower display shows NoMA

4 to 20 mA open loop warning when

4 to 20 mA is enabled in Options Menu

Check Loop wiring or turn off in Options Menu

Lower display shows DESC

High condensation

Check for leaks or replace desiccant pouch

Lower display shows LAMP

Lamp failed

Contact factory for assistance

Lower display shows FAIL

Major system fault

Return to factory for service

Readings are higher than expected

Bubbles in solution

Ensure that the drain vent is open and is not obstructed.

Apply back pressure.

Install an optional Stilling/Bubble Chamber

(4150-0003, 159 001 587).

Condensate or leaky cuvette

Check À ow through cuvette for condensate or leaks.

Flow-through cuvette dirty

Clean cuvette.

Instrument out of calibration

Recalibrate

Readings are erratic

Bubbles in solution

Ensure that the drain vent is open and is not obstructed.

Apply back pressure.

Install an optional Stilling/Bubble Chamber

(4150-0003, 159 001 587).

Debris in À ow-through cuvette

Clean debris from cuvette

Readings are lower than expected

Instrument out of calibration

Recalibrate.

Display shows "Err CAL"

Calibration error or bad standard used

Press the up key to recalibrate (see calibration) or

replace the standard.

Upper display À ashes

Sample Over-Range

Check sample. Sample may be too high to read.

Troubleshooting