Plumbing – GF Signet 4150 Turbidimeter User Manual

Page 4

4

Signet 4150 Turbidimeter

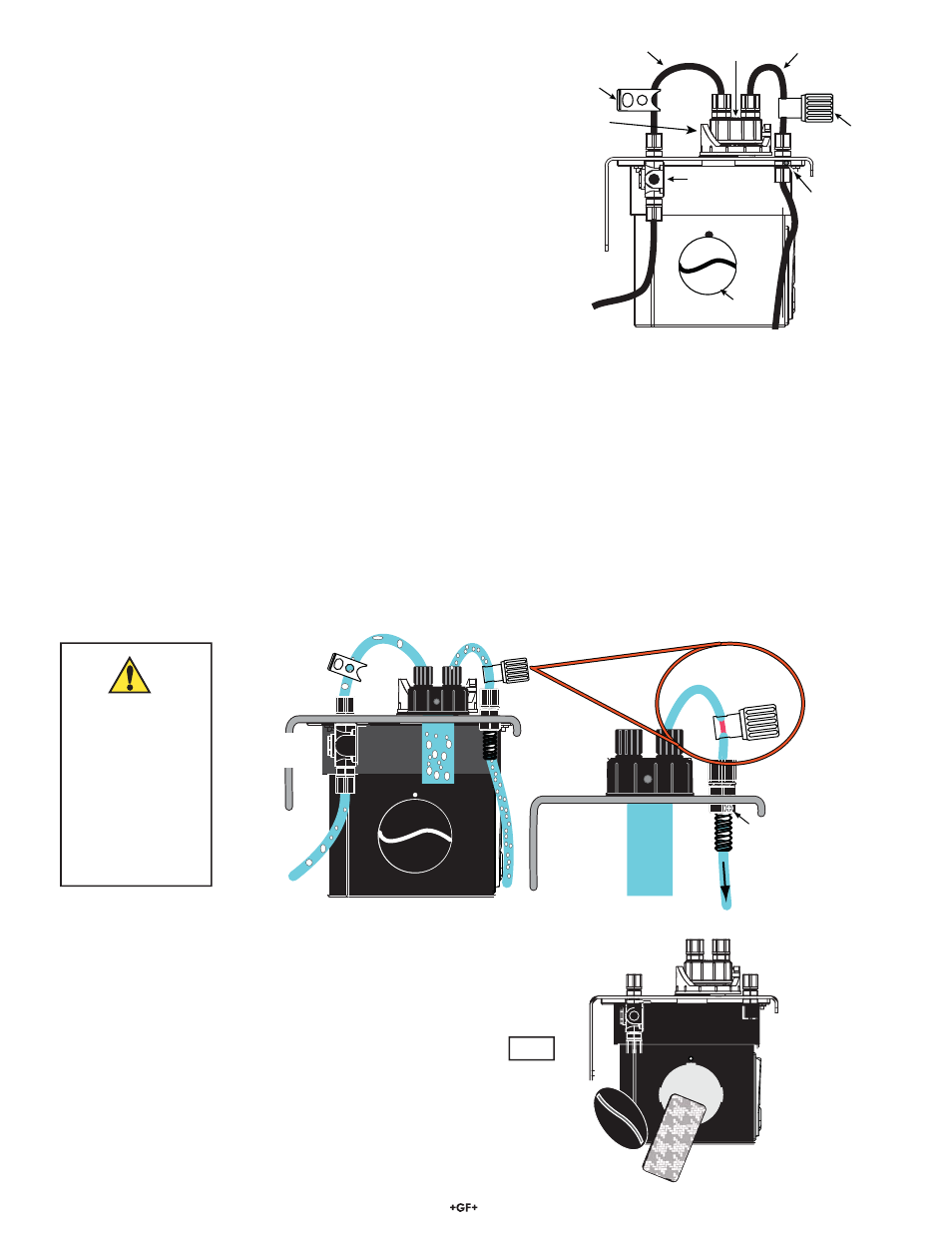

Adjust the Flow to Eliminate Bubbles

The cuvette must be free of air bubbles to provide accurate measurement. The 4150 provides two tools to make this adjustment.

Open the SHUTOFF CLAMP to allow water to À ow through the cuvette.

1. If the À ow is gravity-fed, remove the screw that is blocking the DRAIN VENT. This allows for atmospheric equalization and helps to

eliminate bubbles. The vent may leak for a few seconds, until the À ow is well established.

2. Adjust the BACKPRESSURE VALVE to prevent air from coming out of solution, which may be observed as tiny air bubbles in

the cuvette.

• Remove the measuring cuvette from the measuring cell and place it in the cuvette holder so it is visible while making these adjustments.

• If bubbles are visible inside the cuvette, turn the BACKPRESSURE VALVE until the bubbles disappear.

If bubbles are still visible inside the cuvette, a Stilling/Bubble Chamber, Signet part number 4150-0003 (159 001 587), can be ordered.

DESICCANT COMPARTMENT

OPEN ONLY FOR MAINTENANCE

Backpressure

Valve

Shutoff

Clamp

Backpressure

Valve

Drain vent

To Drain

Pressure

Regulator

The Inlet pressure

regulator is factory

set. Do not adjust!

Contact the factory

if inlet pressure

will exceed 50 psi!

A modi¿ ed tubing

connection may be

required.

Plumbing

• Use 8 mm (5/16 in.) OD, 5 mm (3/16 in.) ID À exible tubing for the water

supply connections.

• Opaque tubing (not supplied) should be used to prevent algae growth if the

tubing will be exposed to sunlight.

• The 4150 requires only 1 psi head pressure to operate.

• The À ow through cuvette is rated for a À ow of 100 mL/m to 1 L/m

(0.026 - 0.26 GPM).

• Inlet water pressure should not exceed 50 psi to avoid damage to the

tubing connection to the regulator.

• The integral pressure regulator is factory adjusted. Do not tamper

with the regulator.

• Fluid temperature must not exceed 50 °C (122 °F).

• The shutoff clamp is used to interrupt the À ow during cuvette maintenance.

• Route the sensor drain tubing to a suitable drain. Do not reintroduce the

drain sample to the process stream.

DESICCANT COMPARTMENT

OPEN ONLY FOR MAINTENANCE

Water

IN

from source

Measuring

Cuvette Assy

Desiccant access

Water

OUT

to Drain

Shutoff

Clamp

Pressure

Regulator

Backpressure

Valve

Drain Vent

Measuring

Cell

Install the Desiccant Pack: (See Fig. 4)

1. Locate the 3-4150.380 desiccant pack.

2. Remove the desiccant pack from its vacuum-sealed package.

3. Open the desiccant access door by turning it counterclockwise.

It is located on the left side of the Turbidimeter.

4. Place the desiccant pack into the instrument's body.

5. Reinstall the access door and rotate clockwise.

DESSICANT COMPARTMENT

OPEN ONLY FOR MAINTENANCE

Desiccant Pouch

3-4150.380

Fig. 4

NOTE: In regions where moisture or high humidity is prevalent, more

than one desiccant pouch may be needed, and desiccant may need

to be monitored more often.