Installation and commissioning, Preassembly – GF Signet 4150 Turbidimeter User Manual

Page 3

3

Signet 4150 Turbidimeter

CAUTION!

Do not touch the glass surface of the cuvette!

Substances on the surface of the glass will cause errors

in the measurement.

Do not remove the glass cuvette from the cap while

holding the assembly over the measuring cell.

Do not allow any debris to fall into the measuring cell.

Do not leave the measuring cell open longer than

necessary. Extended exposure to the atmosphere may

shorten the effective life of the desiccant.

Installation and Commissioning

Mounting & Site Selection

The 4150 is designed to be wall mounted. All the necessary hardware is included.

• Mount the 4150 within 2 - 3 meters (6 - 10 ft) of the sampling point to ensure a quick

response time.

• It is recommended an isolation valve (NOT provided) be used to interrupt the inlet À ow

to the Turbidimeter.

• For ease of service there should be about 20 cm (8 in.) free area above the instrument

for calibration and cuvette maintenance.

• Choose a location that is easily accessible for operation and service.

• The display should be positioned at eye level.

• Four pan head screws and four wall anchors are provided to mount the wall bracket.

• The overall mounting dimensions of the instrument are shown on page 2. A mounting template is provided.

• Mount the Turbidimeter according to local electrical, building, and plumbing codes and seismic requirements.

Preassembly

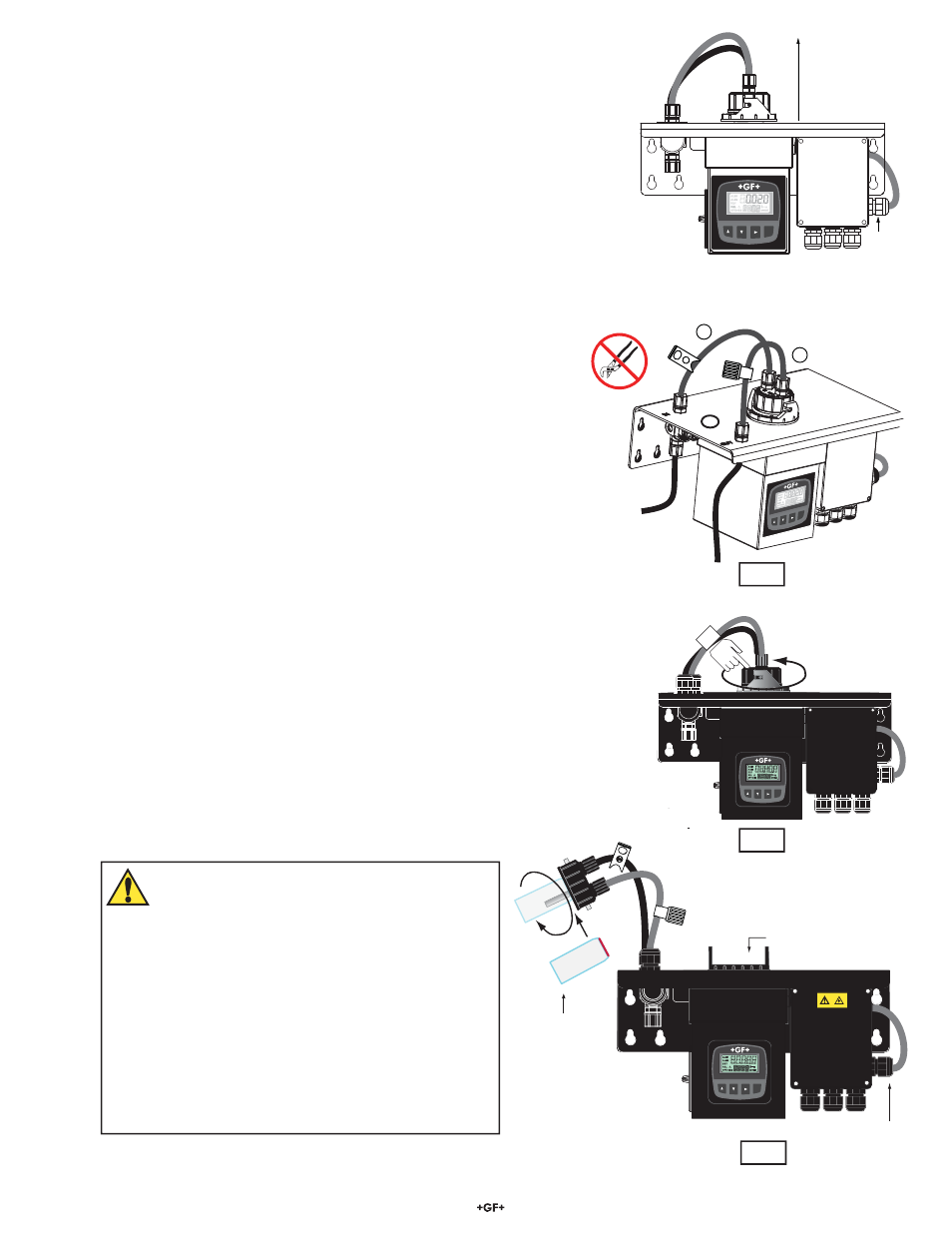

Install Connection Tubes To The Measuring Cell:

1. Locate Tubing Kit 4150-0005 and install the tube kit with the shutoff clamp

(labeled “IN”) to the nipple assembly marked “IN” on the Turbidimeter and to the

measuring cell nipple marked "IN". See Fig. 1.

2. Install the tube kit with the small back pressure valve to the nipple assembly

marked “OUT” on the top right front corner of the turbidimeter and to the

measuring cell nipple marked “OUT”. See Fig. 1.

Note: Hand tighten only. Do not use any tools.

Install the Glass Cuvette: (See Fig. 2 and 3)

The Calibration Kit should be available for this procedure.

1. Locate and have ready the special cleaning cloth that comes with the Calibration

Kit.

2. Locate the glass measuring cuvette. Remove it from its shipping package. Do not

touch the glass. Take caution when handling the cuvette, being careful not to

scratch or mark the glass surface.

3. Unlock the measuring cell by holding the measuring cell with one hand and

twisting the measuring cell lock ring counter-clockwise.

4. Inspect the red gasket in the measuring cell for any defects, tears or dirt. Clean or

replace if necessary.

5. Carefully thread the glass cuvette on the measuring cell. Hand tighten, being

careful not to over tighten the cuvette. Over-tightening may cause the cuvette to

crack or break.

6. Clean the glass cuvette with the special cleaning cloth that comes in the

Calibration Kit. Do not use any other cloth.

7. Insert the measuring cell assembly back into the instrument and rotate the locking

ring clockwise to secure the assembly.

Signet Turbidimeter

ENTER

Measuring Cell

Sensor Interconnect cable

Cuvette

Fig. 3

Signet Turbidimeter

ENTER

Sensor

Interconnect

Cable

Provide 8 in. clearance

for maintenance.

Fig. 1

Signet T

urbidimeter

ENTER

1

2

Signet Turbidimeter

ENTER

Fig. 2