Veris Technologies MSP3 - Operating Instructions User Manual

Page 68

Pub. #OM17-MSP3

5-4

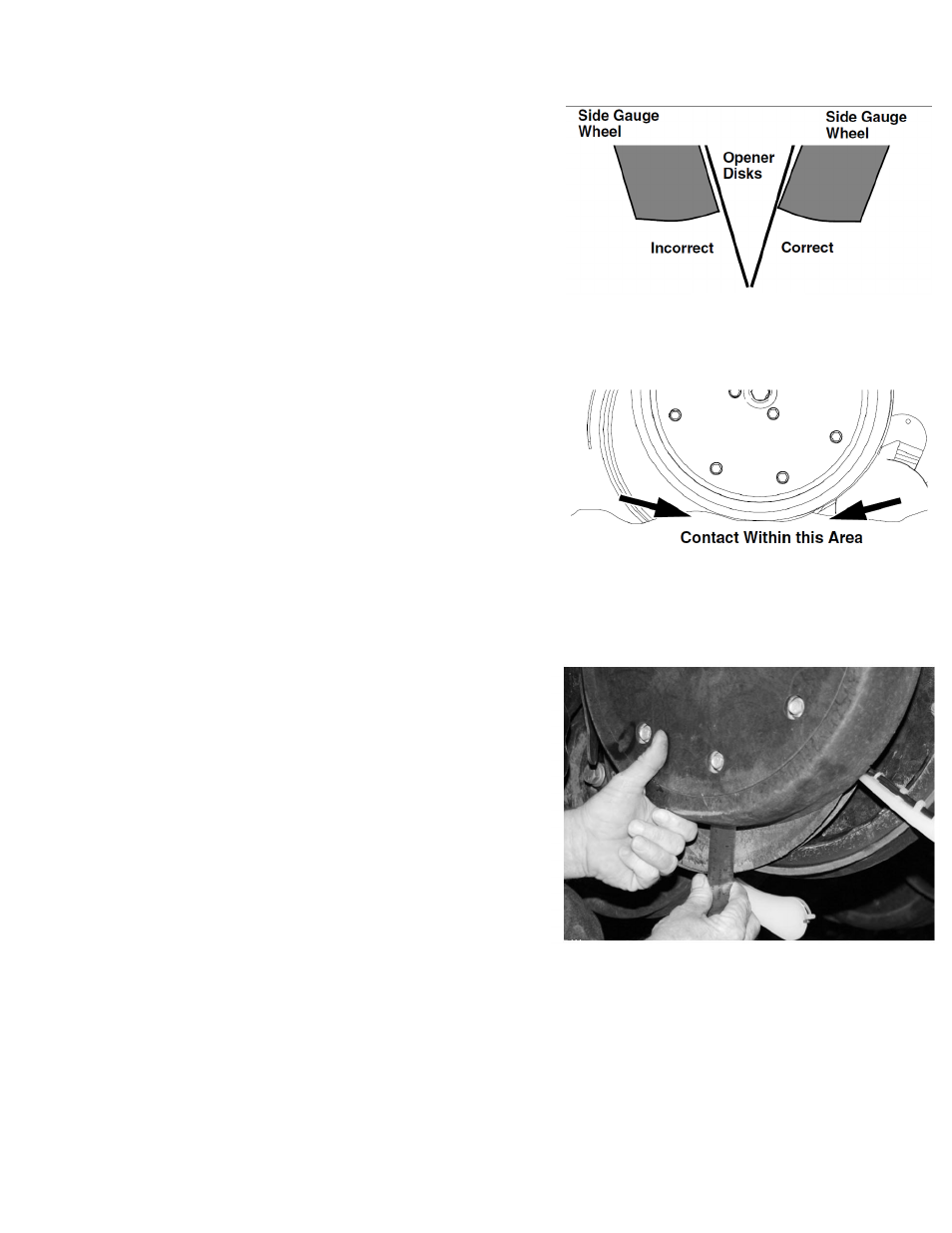

Side Gauge Wheel Adjustment

Refer to Figure 10 and Figure 11

Disc-to-wheel angle and clearance ideally has the wheel

just touching the disk when the wheel is raised to sensing

depth (is up against the stop set by t

he “T” handle.

The goal is to have both disks and wheels turn freely, but

keep soil and trash from getting between them.

These two adjustments interact with each other. Changing

one requires at least checking the other.

In addition to changing the disk angle due to changing

depth or new field conditions, these two settings may

need attention over time as the disk and wheels wear

from normal use. This adjustment will also need to be

made if any opener components are replaced.

Refer to Figure 11

For 2in (5.1cm) sensing depth, adjust side gauge wheel

angle so wheels contact row unit disks at the bottom of

wheel. Check with row units in soil so wheels are held

up.

At the same time, keep side gauge wheels close to

opener disks so openers do not plug with soil or trash.

Note: Wheels should be out far enough so disks and

wheels turn freely.

Refer to Figure 13 on page 5-5

To adjust side gauge wheels:

1. Raise the implement.

2. Loosen hex-head bolt (1) . Move wheel and arm out

on O-ring bushing.

3. Loosen pivot bolt (2) Turn hex adjuster (2) so

Indicator notch (4)

is at 5 o’clock to 7 o’clock.

Note: Use this as the starting point for adjustment.

4. Move wheel arm in so side gauge wheel contacts

row unit disk. Tighten hex-head bolt (1) to clamp arm

around bushing and shank.

Refer to Figure 12

5. Check wheel-to-disk contact at 2in (5.2cm) sensing

depth. Lift wheel 2in, check contact and release.

When let go, wheel should fall freely.

• If wheel does not contact disk at bottom to area where

blade leaves contact with soil, move hex adjuster until

wheel is angled for proper contact with disk.

Figure 10

Figure 11

Figure 12