Veris Technologies MSP3 - Operating Instructions User Manual

Page 18

Pub. #OM17-MSP3

3-3

Flow control settings:

Open center hydraulic systems

1)

Set poppet valve in “up” raised position, this allows flow back to tank

2) Set engine at field rpm

3)

Set pH controller to “Manual” and run sampling shoe up and down, timing the cycle time.

4) If sampler raises in approximately 1.5 -2 seconds, leave flow control as is, if not, adjust control

arm upward or downward to achieve desired speed.

Closed center hydraulic systems

1) Set poppet valve in down position. Push down and rotate so that rolled pin locks into closed

position. This blocks flow and allows the pump to de-stroke when the directional valve is in

the neutral position.

2) Adjust flow control valve to full open position.

3) Set engine at field rpm.

4) Run sampling shoe upward and adjust raise time to approximately 1.5-2 seconds using

throttling valve

on tractor’s remote coupler

Note: Excessive sampling shoe speed can

damage electrodes.

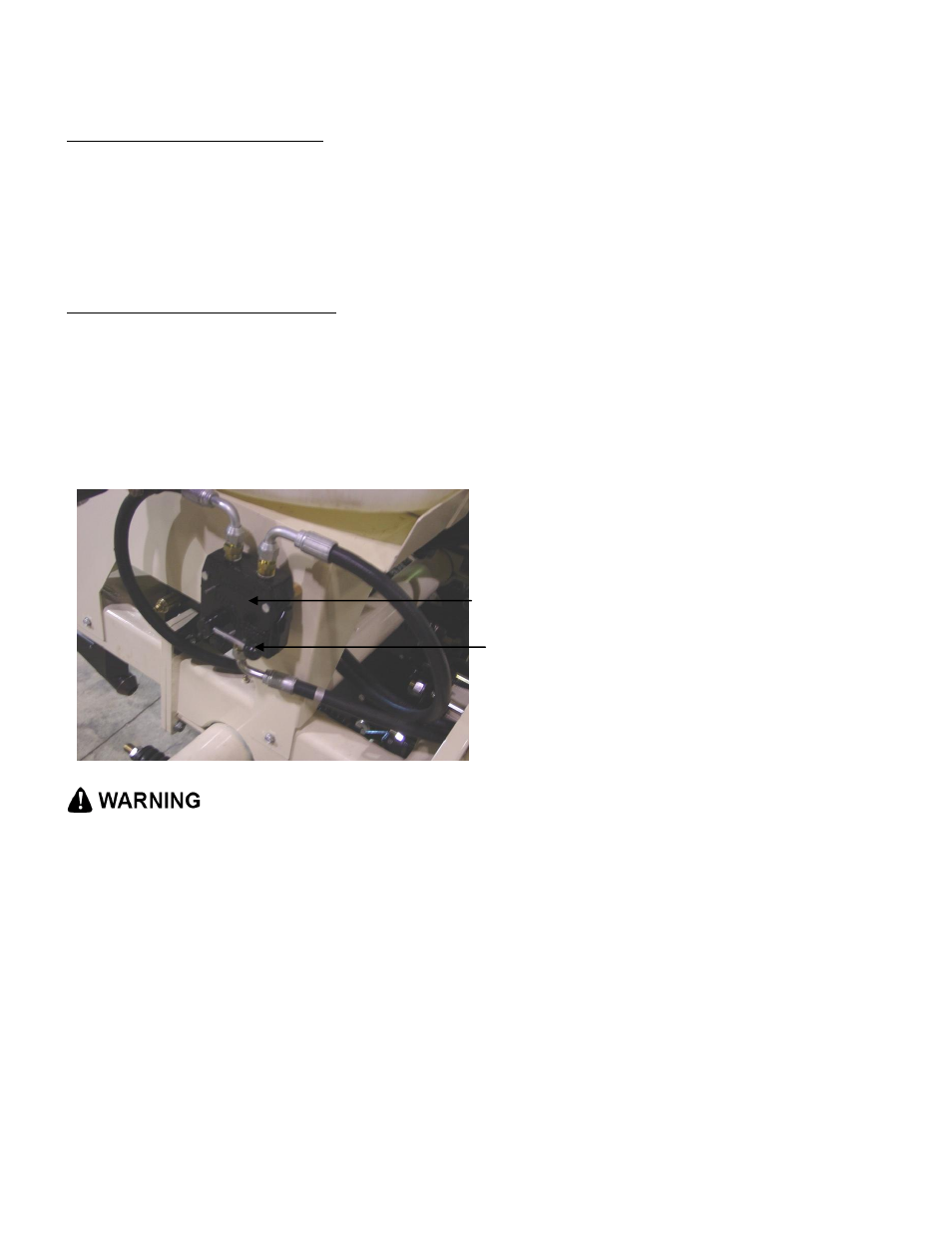

Flow control valve

Adjustment control arm

Figure 4

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard

by relieving pressure before disconnecting hydraulic lines. Use a piece of paper or card-board,

NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and high-

pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

Flush and fill tanks with tap water; clean any foreign matter out of tank using ball valve clean-out.

Set ball valve to open position, allowing water to flow to pumps.