Configure backflushing – M&C TechGroup CSS-VC2 Operator's manual User Manual

Page 34

34

Gas sampling and gas conditioning technology

14.1a-ME

16.3

CONFIGURE BACKFLUSHING

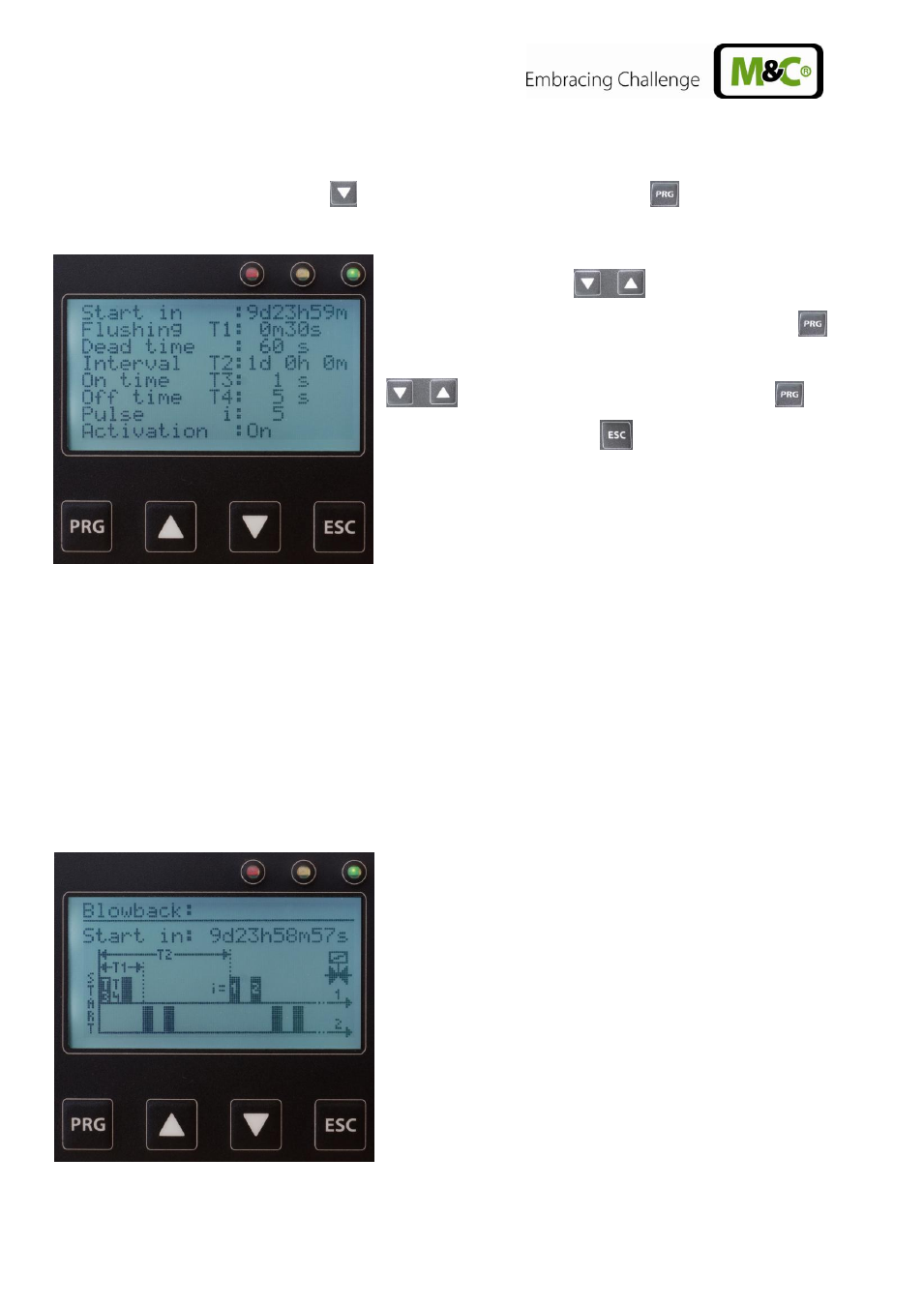

By 3 x pressing of the arrow key,

then 1 x pressing of the PRG key,

the following view

appears when the backflush module is connected:

Using the arrow keys,

the parameters to be

changed can be selected. By pressing the PRG key,

the parameter can now be changed with the arrow keys

and then confirmed with the PRG key

or

discarded with the ESC key

.

Here the backflushing of gas sampling probes is determined:

Start in

= specifies the time of the first backflushing.

Flushing time T1 = Duration of backflushing in a channel

Deadtime

= Delay after the end of backflushing in channel 2 until the indication

shows "Measure" (changeover switch on the backflush module is switched)

Interval T2

= Period until the next backflush

On time T3

= Duration of a backflush pulse

Off time

= Duration between backflush pulses

Pulse number i = Number of resulting backflush pulses (cannot be entered)

Activation

= Backflush programme is to run (on) or not (off). When deactivating, "Start in" = 0

is set.

A programmed backflush runs always automatically after

a delay of T1 on two channels. Thus, for example 2 gas

sampling probes directly following one another or first the

internal probe (/ BB/F), and then the pre-filter (/ BB) are

backflushed. The dead time for channel 1 is therefore

always extended to T1.

If only one gas sampling probe is backflushed, T1 must

be added to the dead time or already represents sufficient

dead time, so that the value for the dead time can be set

to 0.

This menu appears only when the communication module is connected in conjunction with the

backflush module (automatic detection).