2 common specifications – MITSUBISHI ELECTRIC FR-S520 User Manual

Page 174

165

4

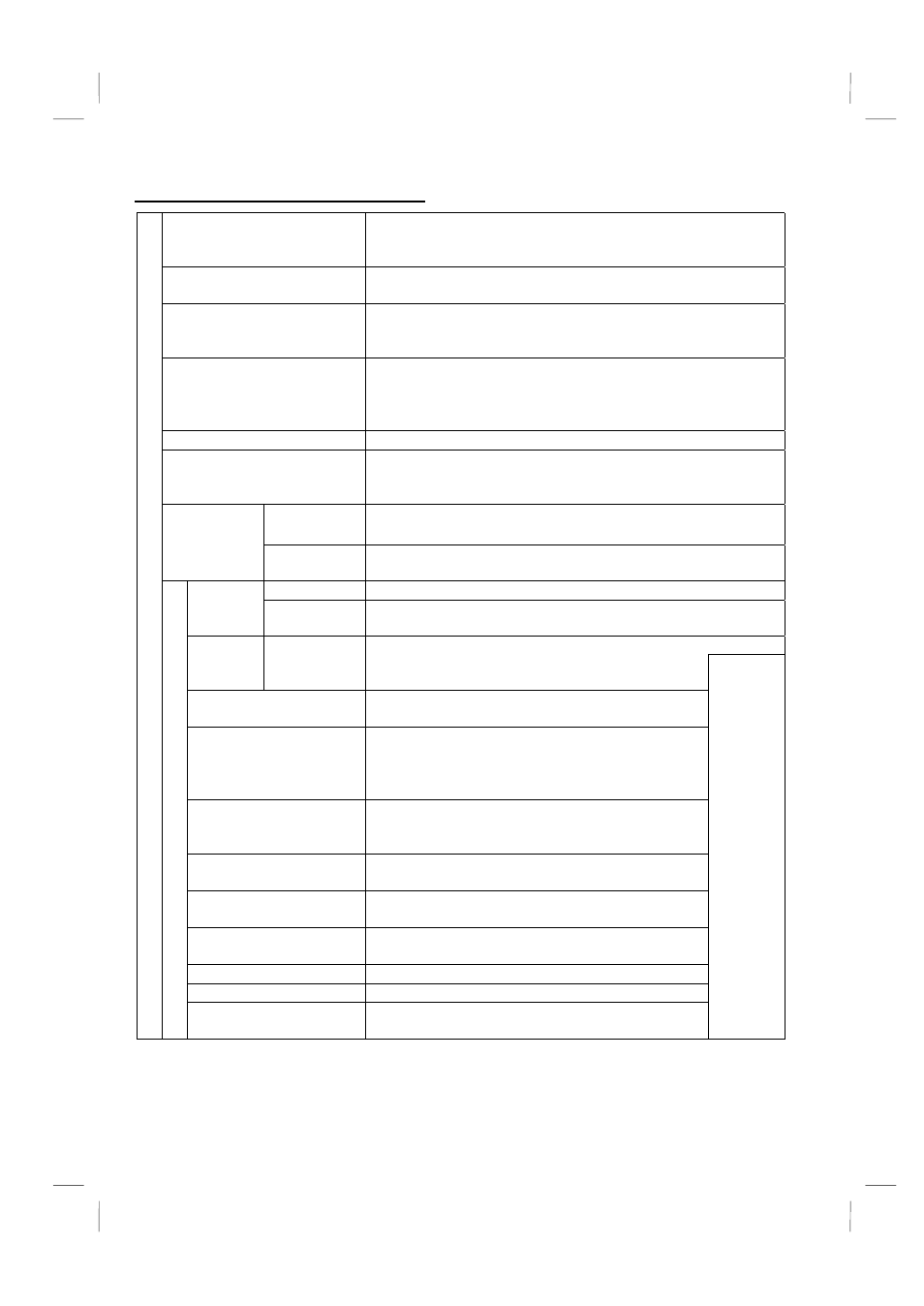

.1.2 Common specifications

Control method

Selectable between Soft-PWM control and high carrier

frequency PWM control, V/F control or automatic torque

boost control selectable.

Output frequency range

0.5 to 120Hz (starting frequency variable between 0 and

60Hz)

Frequency setting resolution

5VDC input: 1/500 of max. set frequency, 10V, 4 to

20mADC input: 1/1000 of max. set frequency. Digital input:

0.1Hz (less than 100Hz), 1Hz (100Hz or higher)

Frequency accuracy

Analog input: Within

±

1% of max. output frequency

(25ºC

±

10ºC (77ºF±18ºF))

Digital input: Within

±

0.5% of set output frequency (when

setting dial is used)

Starting torque

150% (at 6Hz) during automatic torque boost control

Acceleration/deceleration

time setting

0, 0.1 to 999s (may be set individually for acceleration and

deceleration), linear or S-pattern acceleration/deceleration

mode selectable.

Regenerative

0.1K, 0.2K ... 150%, 0.4K, 0.75K ... 100%, 1.5K ... 50%,

2.2K, 3.7K ... 20%,

Braking

torque (*2)

DC braking

Operation frequency (0 to 120Hz), operation time (0 to 10s),

operation voltage (0 to 15%)

Analog input

0 to 5VDC, 0 to 10VDC, 4 to 20mA

Frequency

setting

signal

Digital input

Entered from control panel.

Start

signal

STF, STR

Forward and reverse rotation, start signal

automatic self-holding input (3-wire input) can

be selected.

Alarm reset

Used to reset alarm output provided when

protective function is activated.

Multi-speed selection

Up to 15 speeds can be selected. (Each speed

can be set between 0 and 120Hz, running

speed can be changed during operation from

the control panel.)

Second function selection

Used to select second functions (acceleration

time, deceleration time, torque boost, base

frequency, electronic overcurrent protection).

Output stop

Instantaneous shut-off of inverter output

(frequency, voltage).

Current input selection

Used to select input of frequency setting signal

4 to 20mADC (terminal 4).

External thermal relay

input

Thermal relay contact input for use when the

inverter is stopped by the external thermal relay.

Jog signal

Jog operation mode selection

PID control valid

Selection for exercising PID control

Cont

ro

l s

pec

if

ic

at

ions

Input

s

ignal

s

PU operation-external

operation switching

Used to switch between PU operation and

external operation from outside the inverter.

Use

Pr. 60 to

Pr. 63 for

selection.