System components, Operator’s manual, Virtual terminal (vt) – Great Plains DICKEY-john MVT Monitor Operator User Manual

Page 12

OPERATOR’S MANUAL

IntelliAg MVT

11001-1643-201401

SYSTEM COMPONENTS

/

3

SYSTEM COMPONENTS

The DICKEY-john IntelliAg MVT is a 2 channel control system for row crop

planters that allows for application of 2 separate products or section of the

planter while simultaneously monitoring up to 84 seed sensors for individual

row performance and population. In addition, the system offers optional

manual individual 24-row section control. The system is capable of

monitoring up to 84 rows, ground speed, 3 hopper level, 3 air pressure, 2

RPM sensors, and 1 lift switch.

NOTE:

The IntelliAg system is

designed to ISO11783 CAN

communication standards

providing the capability of

communicating with other

manufacturer’s ISO

11783-compatible equipment.

The IntelliAg system includes the following required components:

•

Virtual terminal

•

Planter Control Module (PCM)

•

Two CAN Terminators

•

Cab and implement harnessing

Optional components include:

•

Working Set Member Modules (WSMB) Up to 5 Working Set Member

Modules (monitors up to a total of 84 rows of seed input)

•

Implement Lift

•

Clutch/Switch Module and Planter Output Module

•

Remote Test Switch (required for Continuous Test and 5 Rev Test)

IntelliAg is compatible with all DICKEY-john sensors.

Terminal Mounts in the cab using:

•

RAM Mount

•

Terminal Mounting Plate

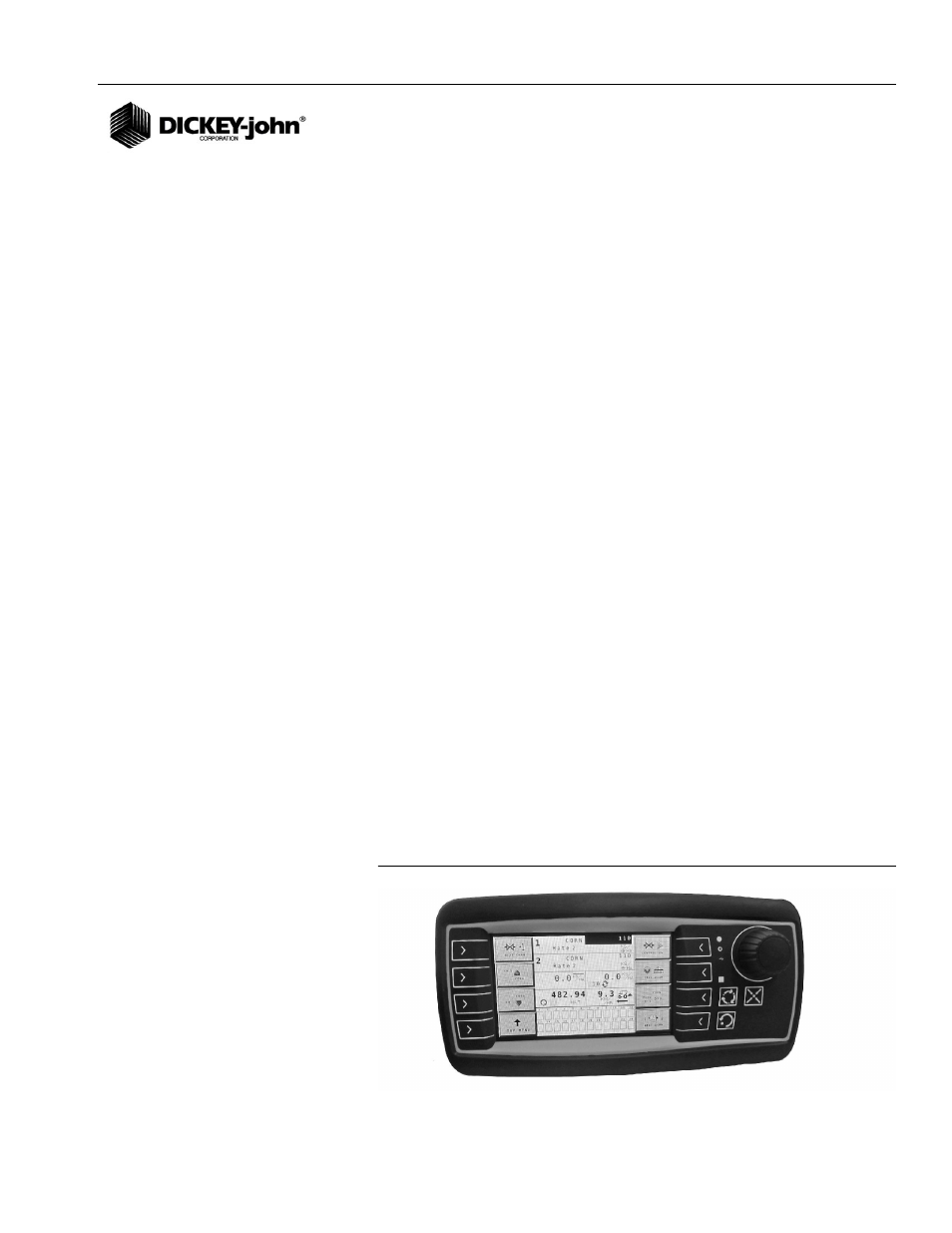

VIRTUAL TERMINAL (VT)

A virtual terminal with 4.3” color display is the main user interface with the

IntelliAg system components to monitor and control product application.

A rotary dial and 8 softkeys are used to navigate the Operate and Setup

screens.

Figure 1

IntelliAg MVT Virtual Terminal