HP 220 User Manual

Page 157

8Ć9

Troubleshooting

C3187Ć90000

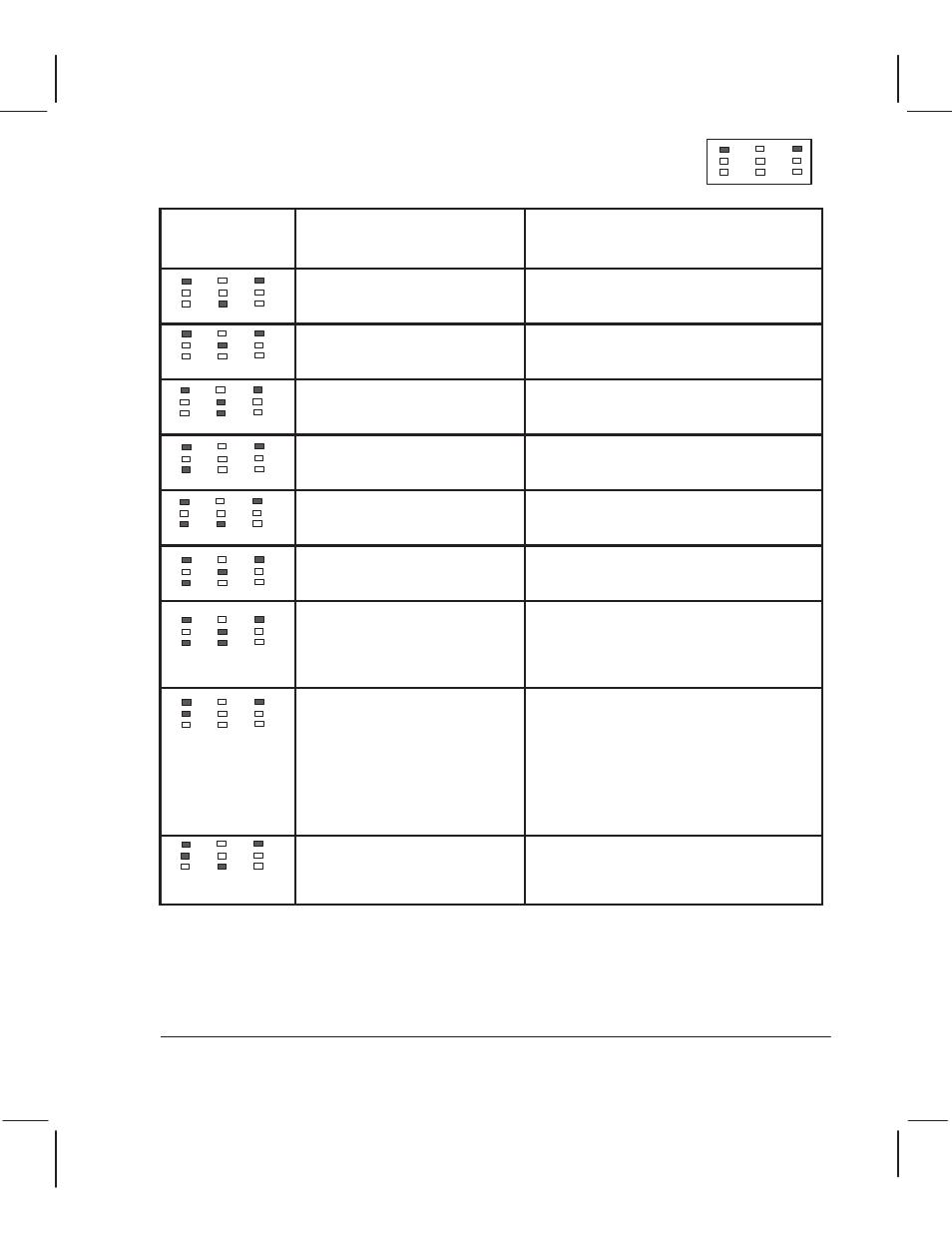

Error

and

Load Media

LEDs lit and steady:

MediaĆpath/servo errors.

LEDs lit

and

steady

Error Number and

Description

Corrective Options

82. Shutdown of media axis

(XĆaxis)

See D later in this chapter, w ServoĆControl

System Failures.

22. Shutdown of carriage axis

(YĆaxis)

See D later in this chapter, w ServoĆControl

System Failures.

86. CarriageĆaxis failure

Check encoder strip, carriage assembly,

trailing cable, main PCA.

50. CartridgeĆcap failure

See D later in this chapter, w Frequent

Cartridge Failure. / Check the service

station, encoder strip and media motor.

114. Error detected in mediaĆaxis

servo feedback loop.

Check media motor, mediaĆmotor encoder

cable, main PCA.

54. Error detected in

carriageĆaxis servo feedback loop.

Check encoder strip, carriage assembly,

trailing cable, main PCA.

118. Bail sensor indicates the bail

is up when it should be down or

vice versa, or the bail drops

suddenly (missing the notch on

the auto cam).

See D later in this chapter, w BailĆLiftĆ

Mechanism Failure. / Use the bailĆsensor

test to help troubleshoot. / Check for

mechanical problems. / Perform the bail

calibration.

146. AccuracyĆcalibration error

Did you load the media in the correct

orientation? / Ensure that the marks are

visible on the plot. If not, check cartridges. /

Ensure that the sheet is cut correctly. /

Perform a cartridge alignment: if alignment

is correct, the problem may be in the main

PCA, media motor or media motor gear; if

alignment is incorrect, the problem may be

in the carriage.

210. MediaĆsensorĆcalibration

error. One of the flags on the

media sensor may be positioned

too far forward or too far back.

Replace the media sensor. If the error

persists, there may be a problem with the

LED on the cartridge carriage: Perform a

cartridge alignment / Replace LED.