Heat & Glo Fireplace XLR-PLUS-PB-AU User Manual

Page 55

55

Heat & Glo • XLR-PLUS-N-AU, XLR-PLUS-PB-AU • 2264-900 Rev. o • 1/13

Note: The lower cover panel must be pushed all the way

down. The outer finishing flanges should line up. The

fireplace opening must be between 15-3/4 in. (400 mm)

and 16-1/8 in. (410 mm) for the decorative fronts to fit

correctly. See Figure 13.4.

Finish and Sealing Joints

All joints between the finished wall sheating and

the appliance must be sealed with non-combustible

materials. Sealants, such as caulk or mastic used to

seal the gap between the wall and the fireplace, should

be rated at a minimum continuous exposure to 149 °C

(300 °F). Wall board joints can be taped and sealed with

combustible drywall tape.

Finishing Around Opening with Gypsum Wallboard

Gypsum wallboard (drywall) joints adjacent to the

fireplace opening require special attention to minimize

potential development of cracking. Hearth and Home

Technologies recommends the following steps to

minimize potential cracks in the finished drywall around

the fireplace opening:

• When installing gypsum wallboard around the fireplace,

install the hole for the fireplace opening in a single

wallboard sheet, if possible. This will minimize the joints

adjacent to the fireplace opening.

• The factory-supplied non-combustible board and the

gypsum wallboard must join on the structural framing,

where applicable. Wallboard and non-combustible board

should be fastened to the framing with at least 1-1/4 in.

(32 mm) long screw fasteners, located within 1-1/2 in.

(38 mm) from each corner, and at no more than 12 in.

(305 mm) intervals along the joint length.

• The wall-board joints should be finished with a Taping

Coat, followed by at least two subsequent Finish Coats

of joint compound.

• For the initial Taping Coat, it is critical that a general-

purpose chemically hardening joint compound, such as

SHEETROCK™ Brand Durabond™ Setting-Type Joint

Compound, be used to fill the joint and embed the mesh

tape. Fiberglass-mesh tape is recommended because it

will provide a more crack-resistant joint than one finished

with paper tape. Let the Taping Coat properly cure before

applying subsequent Finish Coats.

• For the second and third finishing coats, it is acceptable

to use a light-weight joint compound and standard

application, curing and sanding methods.

• Do not operate the fireplace during the drywall finishing

process. Allow the finish coat to cure for at least 24 hours

prior to using the appliance.

Painting

If desired finishing includes a painted wall, 100% acrylic

latex with compatible primer is recommend around the

appliance. Oil-based or standard acrylic paints may

discolor due to heat exposure.

Wallboard Joint-Crack Prevention and Repair

Wallboard joints around the fireplace will be affected by

exposure to elevated temperatures, along with other en-

vironmental and structural factors. The specific methods

presented in the previous section will help prevent or

minimize development of cracks.

If a crack does emerge adjacent the fireplace, it can be

permanently repaired by filling it with spackling paste or

paintable latex caulk, followed by repainting.

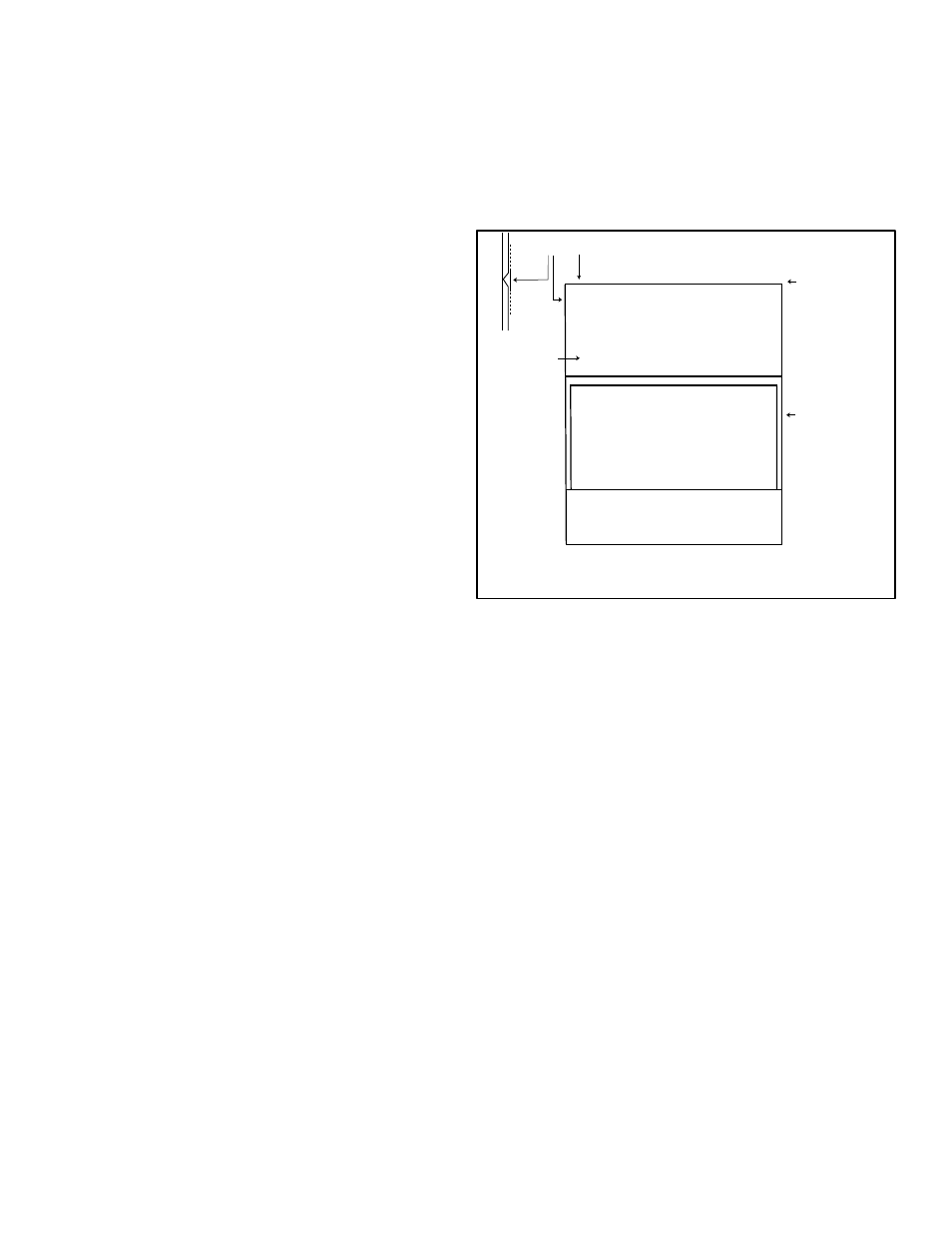

V-JOINT TO PLATERBOARD & WHITE INSULATION BOARD, BUTT JOIN EACH AND BACK FILL WITH

CORNICE CEMENT. OVERLAY JOIN WITH FIBERGLASS TAPE AND TROWEL TOP COAT OVER.

SIDE

ELEVATION

ENTIRE INSULATION

BOARD TO BE

TOP COATED

WHITE INSULATION BOARD

FIBERGLASS TAPE

ONLY ON JOINT

12 mm CLEARANCE

TO COMBUSTIBLES

Plasterboard to be adhered to lower panel using silicone

(no screws to be used).

Figure 13.5 White Insulation Board

• Retain 12 mm clearance between plasterboard

and vertical sides of unit. Butt join plasterboard

and white insulation board at top of heater. USING

ONLY FIBERGLASS TAPE finish insulation board to

plasterboard as per normal plasterbaord procedures.

Ensure that top coat finish extends down to top of heater,

as indicated in diagram below. Insulation board will

remain exposed as part of the finished plaster face.

Gas Pipe Requirements

1. If polyethylene composite gas pipe is to be used, a

clearance of 150 mm must be maintained from all flues.

2. Polyethylene composite gas pipe must not be used as

the final connection onto the heater.

3. Leave a 1 m. tail of 1/2 in. (13 mm) copper pipe.