8 optional components, 1 the 5100-8a channel expansion option, 8 optional – LINK Systems 5100-8 Tonnage & Analog Signal Monitor User Manual

Page 70: Components, The 5100-8a channel expansion option, Figure 39: 5100-8 circuit board option connectors, 69 for inform, Figure 37: load cell hit with bad tie-rod tension, Figure 38: load cell hit with good tie-rod tension

Doc

#:

L-802-1110 Page

68 Rev.

02

equal loads are on the load cells. If the channels with much higher calibration numbers now give

tonnage readings much larger than the channels with lower calibration numbers improper tie rod tension

is indicated.

Channel 1

Tonnage

EXIT

NEXT

CHANNEL

SELECT

PEAK/DATA

WINDOW

Use the

and keys to move the graph cursor

Use the and keys to move the parameter cursor

OVERLAY

GRAPHS

Angle: 180.0°

Tonnage: 92.8 Tons

Cursor Readout

CHANNEL 1 TONS - PEAK SETPOINTS

DW 1

DW 2

DW 3

DW 4

PEAK

INFO

Start

End

100.0

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

-10.0

-20.0

-30.0

-40.0

-50.0

160.0°

180.0°

200.0°

160°

200°

View Pts: 1085

ENTER PAN

ZOOM MODE

SEND

GRAPH

SHOW REF

GRAPH

HI LIM

LO LIM

RV LIM

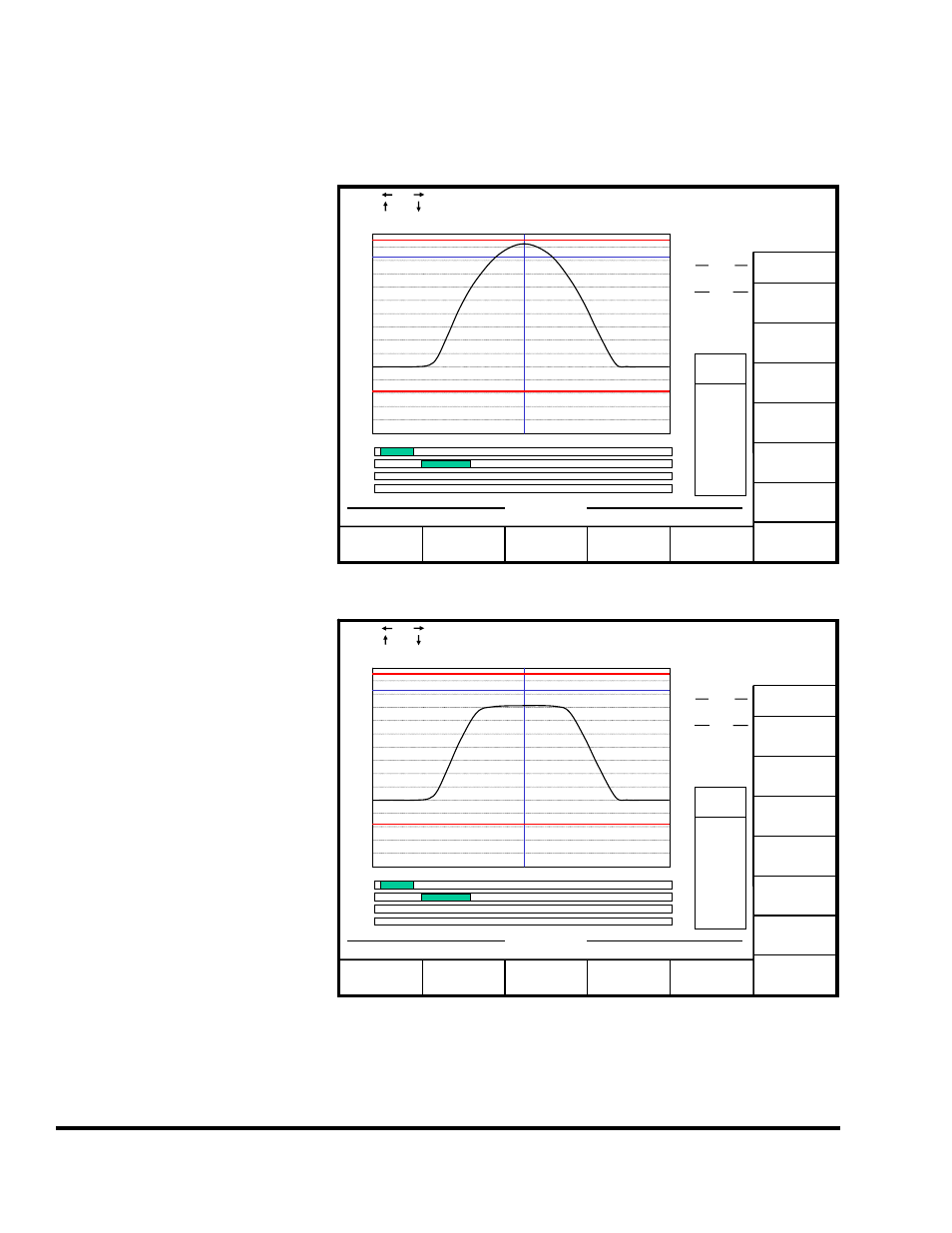

Another way to check for loose tie

rods is to check the tonnage graph

when hitting load cells at near

machine rating. Figure 38 shows a

tonnage graph of a typical load cell

hit on a machine with tie rods that

are in proper tension. There is a

characteristic “hump” shape with a

rounded top. Actual hits may not

be quite as smooth but should have

the same general shape. Figure 37

shows the characteristic shape for a

channel on an upright with a loose

tie rod. The “hump” flattens out at

around 70 tons. This means that

instead of the 150 tons of preload

the tie rod should have, it had only

70 tons of preload. Not only does

this result in the inability of the

tonnage monitor to read the proper

tonnage on that channel, but this

can cause all kinds of machine,

tooling, and quality problems

because whenever the channel

exceeds 70 tons, the upright is

actually separating from the bed

and crown of the press. This can

cause hit to hit variation in the

alignment of the press itself. Note

that the flattening of the “hump”

can occur at almost any level

depending on how loose tie rods

are.

Channel 1

Tonnage

EXIT

NEXT

CHANNEL

SELECT

PEAK/DATA

WINDOW

Use the

and keys to move the graph cursor

Use the and keys to move the parameter cursor

OVERLAY

GRAPHS

Angle: 180.0°

Tonnage: 72.1 Tons

Cursor Readout

CHANNEL 1 TONS - PEAK SETPOINTS

DW 1

DW 2

DW 3

DW 4

PEAK

INFO

Start

End

100.0

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

-10.0

-20.0

-30.0

-40.0

-50.0

160.0°

180.0°

200.0°

160°

200°

View Pts: 1085

ENTER PAN

ZOOM MODE

SEND

GRAPH

SHOW REF

GRAPH

HI LIM

LO LIM

RV LIM

L

95.0

82.3

18.2

CHANGE

NUMBER

GRAPH

SETTINGS

SHOW BY

TIME

Cap Pts: 3143

Figure 37: Load Cell Hit with Bad Tie-Rod Tension

L

95.0

82.3

18.2

CHANGE

NUMBER

GRAPH

SETTINGS

SHOW BY

TIME

Cap Pts: 3143

Figure 38: Load Cell Hit with Good Tie-Rod Tension