2 faceplate connections and indicators, 3 wiring power for the module, Faceplate connections and indicators – LINK Systems 5100-8 Tonnage & Analog Signal Monitor User Manual

Page 53: Wiring power for the module, Figure 22: tonnage monitor faceplate, 6 installation, 1 mounting the module

Doc

#:

L-802-1110 Page

51 Rev.

02

6 INSTALLATION

The Tonnage and Analog Signal Monitor module can be used with the OmniLink II Press Automation

Control system or with the OmniLink 5000 Press Control system. In both cases, the unit is tied to the

control system with a high speed serial bus.

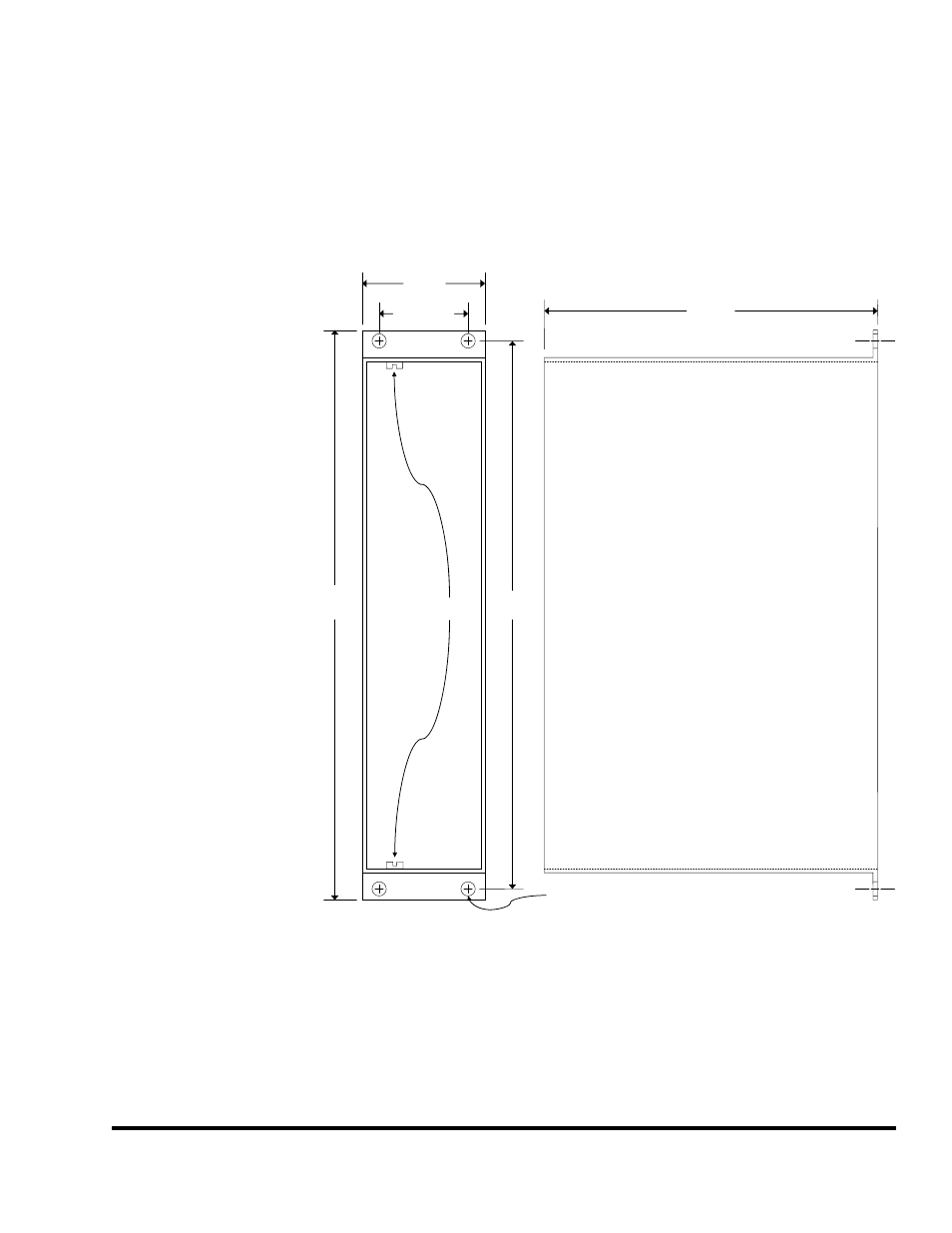

6.1 Mounting the Module

The Tonnage and

Analog Signal Monitor

module can be mounted

in the press control

enclosure or in its own

enclosure. If the unit is

to be mounted in a

location subject to

shock and vibration,

shock mounts are

required. Either the

card rack assembly can

be shock mounted or

the enclosure in which

it is installed can be

shock mounted.

In selecting the

mounting location, the

wiring connections for

the unit should be

considered as discussed

in section 6.4. After the

mounting location has

been determined, the

card rack assembly can

be secured with four

screws. Mounting

dimensions are shown

in Figure 21. Note that

even though the card

rack is 6.1 inches deep,

an additional 1.5 inches should be set aside for the connectors and wiring that connect to the faceplate of

the unit.

C

L

C

L

C

L

C

L

C

L

C

L

6.1in

(155mm)

10.0in

(254mm)

10.50in

(267mm)

1.625in

(41.3mm)

2.25in

(57mm)

0.267in dia. (4 places)

(6.78mm)

Card

Guides

Figure 21: Unit Mounting Dimensions

To assemble the module, simply slide the Tonnage Monitor module into the single slot card rack. The

module slides into two card guides in the rack, and is held in place with two knurled screws at the top

and bottom of the module.