4 wiring high speed serial bus cable, Figure 23: power connector – LINK Systems 5100-8 Tonnage & Analog Signal Monitor User Manual

Page 55

Doc

#:

L-802-1110 Page

53 Rev.

02

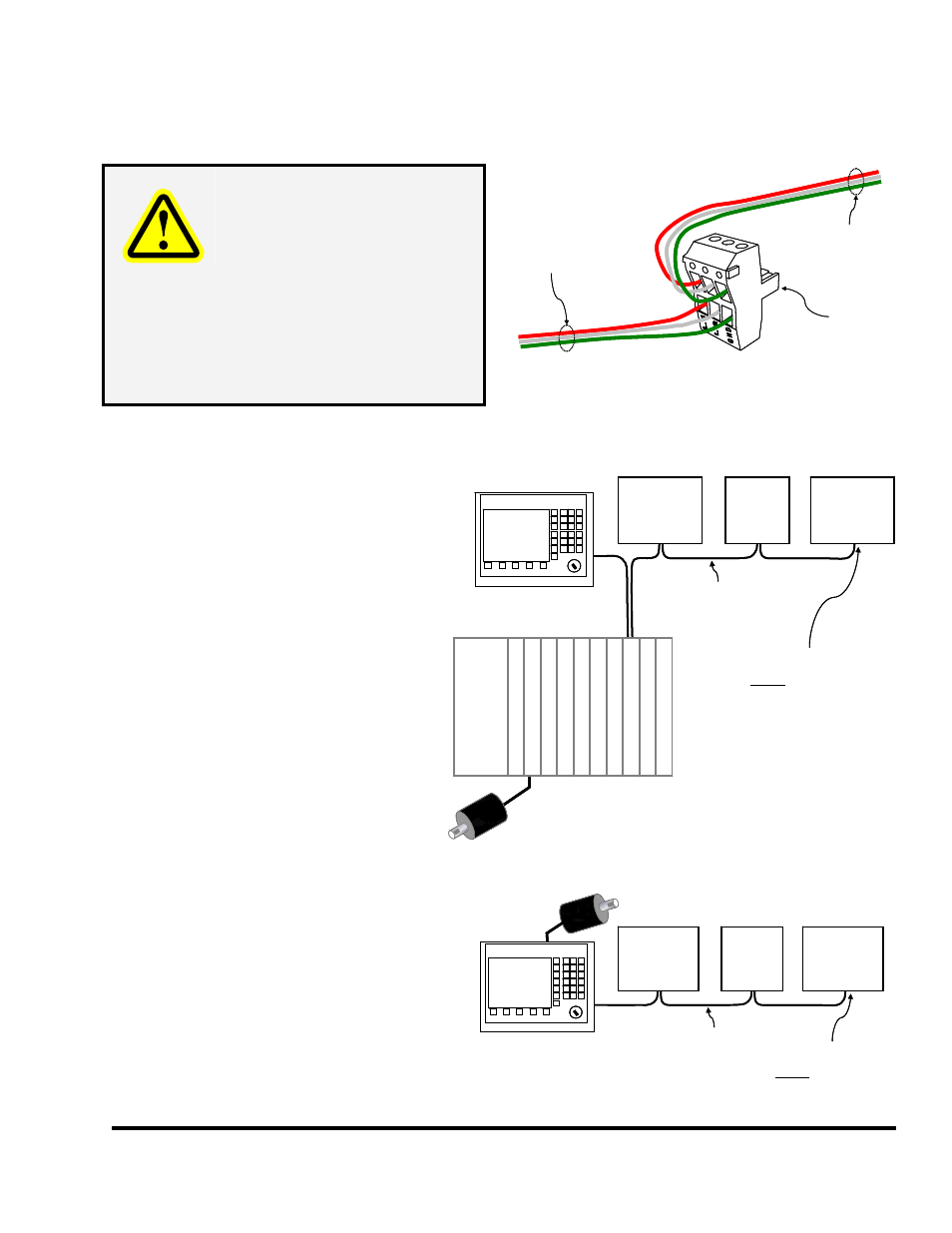

speed serial cable, the power cable does not have to be “daisy-chained”. Power can be taken from any

convenient source. The power wiring should be at least 16 GA.

Power To

Next Module

(16 GA red, white,

And green wires)

Power From

Last Module

(16 GA red, white,

and green wires)

Power

Connector

For Module

Power To

Next Module

(16 GA red, white,

And green wires)

Power From

Last Module

(16 GA red, white,

and green wires)

Power

Connector

For Module

WARNING!

While the Tonnage & Analog

Signal Monitor (and most newer

Link products) has a “universal

power supply” and can operate

from 88-264VAC, some older

modules operate on 110VAC

only. Verify the power

requirements of all modules in

the system before “daisy-

chaining” the power from a

higher voltage source!

Figure 23: Power Connector

6.4 Wiring High Speed Serial

Bus Cable

OmniLink II LCD

Operator Terminal

OTHER

OMNILINK II

OPTIONS

(If Present)

High Speed

Serial Bus

Cable

OMINLINK 5000

PRESS CONTROL

Tonnage

& Analog

Signal

Monitor

OTHER

OMNILINK II

OPTIONS

(If Present)

Pow

e

r

C

o

nn

ec

ti

o

n

Mod

u

le

L

ogi

c Mo

dul

e

R/D Mo

dul

e

1st Inpu

t

Mo

d

u

le

2

n

d I

n

p

u

t

Mo

du

le

Ou

tp

u

t Dri

v

e

Hi Sp

eed

In

ter

fa

c

e

Resolver/Encoder

NOTE: Last Option on

High Speed Serial Bus

MUST be terminated

(see text for details)

OmniLink II LCD

Operator Terminal

OmniLink II LCD

Operator Terminal

OTHER

OMNILINK II

OPTIONS

(If Present)

High Speed

Serial Bus

Cable

OMINLINK 5000

PRESS CONTROL

Tonnage

& Analog

Signal

Monitor

OTHER

OMNILINK II

OPTIONS

(If Present)

Pow

e

r

C

o

nn

ec

ti

o

n

Mod

u

le

L

ogi

c Mo

dul

e

R/D Mo

dul

e

1st Inpu

t

Mo

d

u

le

2

n

d I

n

p

u

t

Mo

du

le

Ou

tp

u

t Dri

v

e

Hi Sp

eed

In

ter

fa

c

e

Resolver/Encoder

NOTE: Last Option on

High Speed Serial Bus

MUST be terminated

(see text for details)

The high speed serial bus cable is a critical

part of the system. Communications with

the operator terminal for settings and

status, crank angle and mode information

from the control, and stop signals to the

control are all sent through this

communications link.

As mentioned earlier, the Tonnage &

Analog Signal Monitor can be used with

both the System 5000 Press Control as

well as the OmniLink II Automation

Control.

When used with the System 5000 Press

control, the high speed serial wiring

should be run in a fashion similar to

Figure 24.

Figure 24: System 5000 High Speed Bus Wiring

OmniLink II Press Automation Control

OmniLink II LCD

Operator Terminal

Resolver or

Resolver/Encoder

OTHER

OMNILINK II

OPTIONS

(If Present)

High Speed

Serial Bus

Cable

OMINLINK II PRESS

AUTOMATION CONTROL

Tonnage

& Analog

Signal

Monitor

OTHER

OMNILINK II

OPTIONS

(If Present)

NOTE: Last Option on

High Speed Serial Bus

MUST be terminated

(see text for details)

OmniLink II Press Automation Control

OmniLink II LCD

Operator Terminal

OmniLink II Press Automation Control

OmniLink II LCD

Operator Terminal

OmniLink II LCD

Operator Terminal

Resolver or

Resolver/Encoder

OTHER

OMNILINK II

OPTIONS

(If Present)

High Speed

Serial Bus

Cable

OMINLINK II PRESS

AUTOMATION CONTROL

Tonnage

& Analog

Signal

Monitor

OTHER

OMNILINK II

OPTIONS

(If Present)

NOTE: Last Option on

High Speed Serial Bus

MUST be terminated

(see text for details)

Figure 25 shows a similar setup using the

OmniLink II Press Automation Control.

While the tonnage monitor module is

shown in the middle of the “string” of

options in both of these examples, it could

also be the last unit in the line.

Figure 25: Automation Control High Speed Bus Wiring