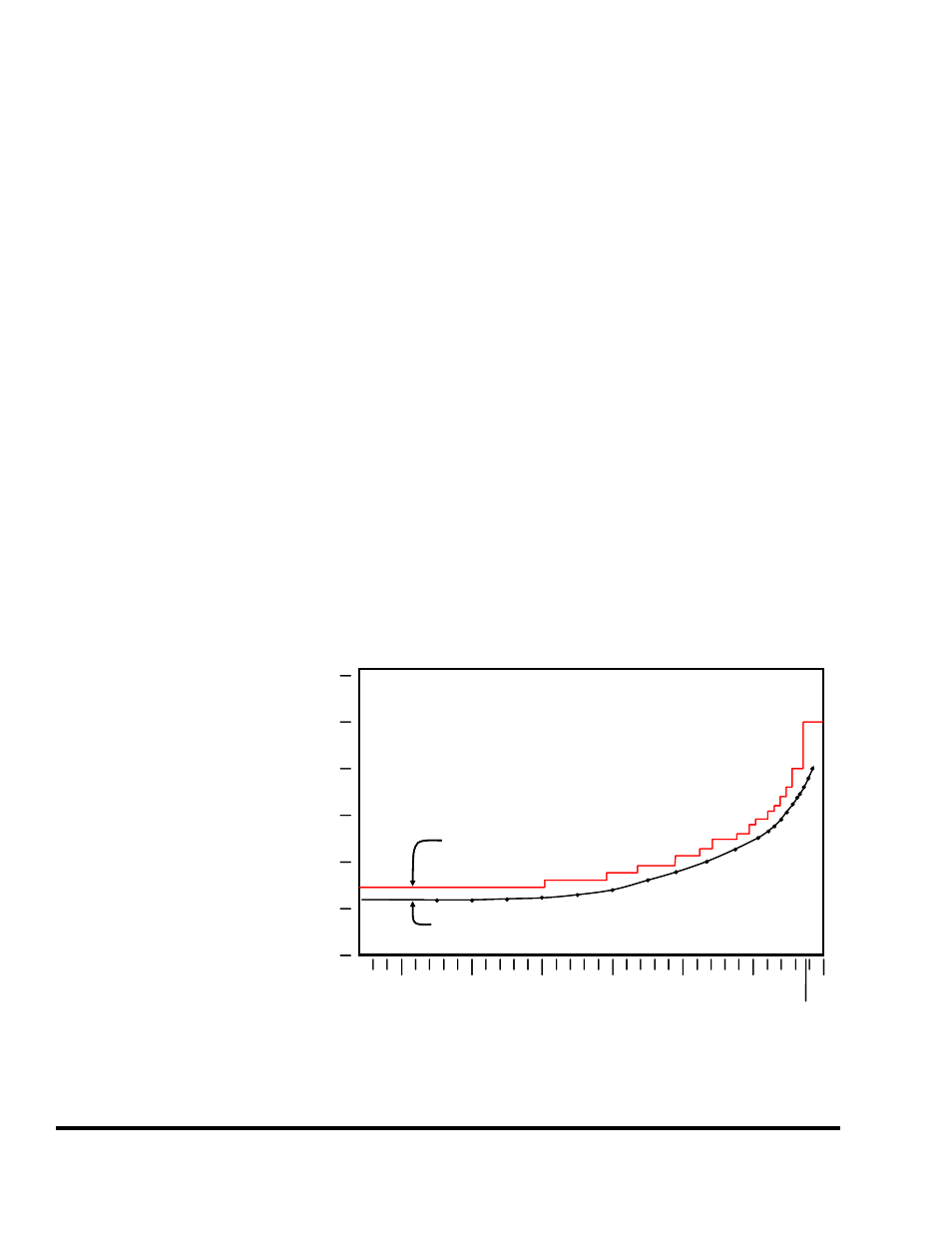

6 the machine rating de-rate table screen, Figure 19: example tonnage de-rate curve – LINK Systems 5100-8 Tonnage & Analog Signal Monitor User Manual

Page 50

Doc

#:

L-802-1110 Page

48 Rev.

02

4.6 The Machine Rating De-rate Table Screen

Press the SELECT key to the right of the “Tonnage Monitor Calibration” in the Tonnage Monitor

Configuration screen as shown in Figure 16 to display the screen shown in Figure 20.

A mechanical power press is typically specified by its manufacturer with a tonnage capacity rating and a

height off of the bottom of the stroke at which this rating applies. One reason for this is that the

mechanical advantage created in the translation of the rotary motion of the crankshaft to the linear

motion of the slide changes depending upon crankshaft angle. The constant torque of the clutch

develops more downward force as the crankshaft angle travels from 90 degrees (mid stroke) to 180

degrees (bottom).

If torque were the only limiting factor, the press could deliver infinite tonnage at the bottom of the

stroke. However, the elastic limits of the press frame place an additional limitation on tonnage near the

bottom. Below the point where the machine is rated, a Machine Rating limit of no more than 125% of

rated capacity is placed on each strain gage mounted to the machine frame in order to stop the machine

before permanent damage is done to the structural members (see section 4.4.3 on page 45 for how this

limit is set).

Above the point where the press is rated, an additional limit can be set so that the torque available from

the clutch is not exceeded. This torque is delivered to the entire machine frame and is measured by

examining only the total tonnage (combined tonnage on all frame members). Since the limit is placed

on the tonnage (and not directly measuring torque), it must decrease as crankshaft angle moves from 180

to 90 degrees (de-rates the machine rating). Tonnage curves are available from the press manufacturer

that describes the amount of total tonnage that can be developed at different points in the stroke.

If desired, the total tonnage

can be de-rated by

examining the press

manufacturers' tonnage

rating curve for a particular

type machine and entering

this information into the

tonnage monitor. The entry

process requires that the

machine curve be divided

into 16 discrete regions

with a single tonnage limit

that applies for each region.

Height off the bottom of

the stroke must be

converted to crankshaft

angle in order to position

each region. Figure 19

shows an example tonnage

de-rate curve for a 12 inch stroke press with a 30 inch connecting rod. Rated tonnage is specified at 0.25

inches off the bottom. In the example, the limits are placed approximately 5% beyond the rating.

150%

125%

100%

75%

50%

25%

0%

30%

35%

6.0

(95°)

5.0

(105°)

4.0

(115°)

3.0

(125°)

2.0

(135°)

1.0

(149°)

0.5

(158°)

0.0

(180°)

0.25

(164°)

Height Off Bottom in Inches

(Crankshaft Angle in Degrees)

%

M

achi

n

e

Ra

ti

ng

Piecewise Approximation For

Total Machine Rating Alarm

Press Rating As Supplied By Manufacturer

150%

125%

100%

75%

50%

25%

0%

30%

35%

6.0

(95°)

5.0

(105°)

4.0

(115°)

3.0

(125°)

2.0

(135°)

1.0

(149°)

0.5

(158°)

0.0

(180°)

0.25

(164°)

Height Off Bottom in Inches

(Crankshaft Angle in Degrees)

%

M

achi

n

e

Ra

ti

ng

Piecewise Approximation For

Total Machine Rating Alarm

Press Rating As Supplied By Manufacturer

Figure 19: Example Tonnage De-rate Curve