Proportional, integral, and derivative, Pulse, width, modulation), Control – YSI 5200A User Manual

Page 70: E 139). th, E 138

YSI 5200A

139

YSI 5200A

138

PID

(Proportional, Integral, and Derivative

)

/

PWM

(Pulse, Width, Modulation)

Control

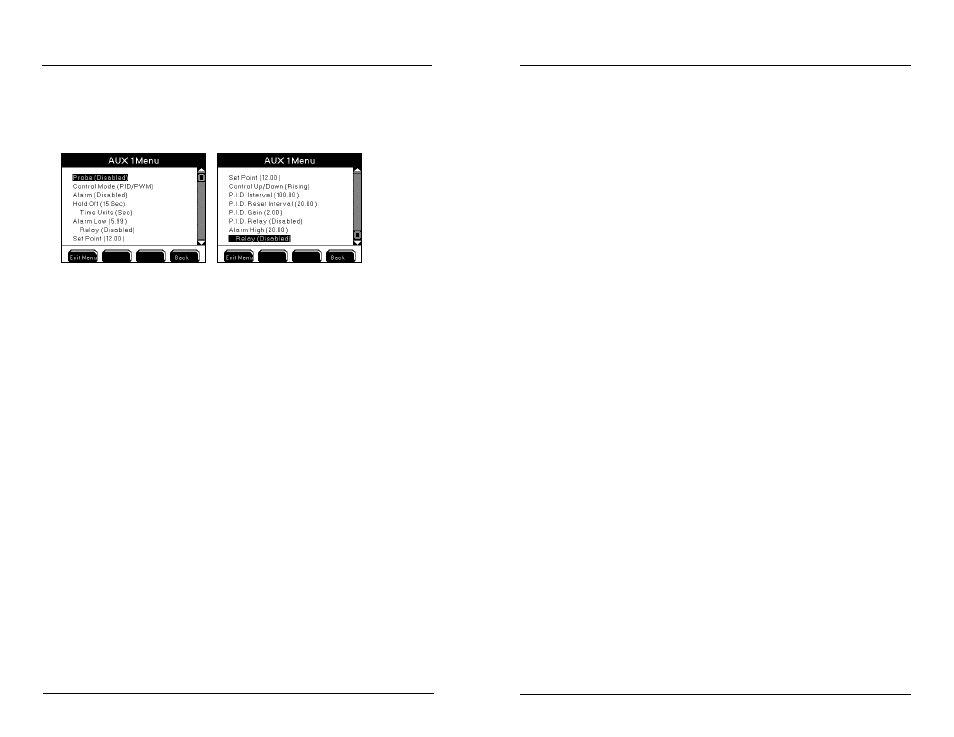

PID/PWM control menu options are shown below for an aux analog system.

PID/PWM Control uses a complex algothrium in determining the best way to sustain

water system value(s) around a set point. PID/PWM control is a feed back control

system. Three factors determine how PID/PWM control seeks to maintain water

system value(s) around a set point. The three factors are:

-the error (distance) from present measurement of input to set point (present time);:

-the duration of the error (accumulation of past errors)

-the speed at which the value is approaching the set point (predicts future errors) ;

The PID/PWM control system is considered active whenever error exists away from

the configured set point. (See PID/PWM up/down control configuration - page

139). The PID/PWM control system is flexible and can be tuned to keep water

systems around their set points even though the environment is exposed to distur-

bances that drive the input value away from set point. An example of a PID/PWM

control system that most readers will be familiar with is a cruise control system in

a car. Acceleration and deacceleration adjustments are continually being made to

maintain the car at a constant speed or set point.

Configure PID/PDW control systems at Sensor Setup menus.

PID/PWM control also allows configuration of high and low alarm systems to

activate peripheral devices and/or to provide alarm notification messages when

alarm condition(s) exist.

Notes:

- Changing control method between PID/PWM and Set Point may result

in invalid setp point, control and alarm value configurations. Always

reconfirm sensor setup system menu configuration when control mode

is changed.

- PID/PWM control is not available for aux digital systems.

Configuring the 5200A

- DO system(s) PID/PWM set point can be configured using either mg/L

or %Sat set point.

PID/PDW Tuning

Each and every water system responds very differently to peripheral control de-

vices due to many factors. Factors that can influence the ability of a control device

to maintain a certain set point include size of system, peripheral equipment such

as pumps, lighting, system location and the like. While PID/PWM tuning is an

important and necessary requirement to properly configure the control system

it is outside the scope of this document to describe the tuning process. There is a

wealth of information available on the www as well as in print. Please familiarize

yourself with additional information in order to further your understanding of the

PID/PWM control method.

Set Point

Configure the set point to be the value at which you’d like the system to ideally

operate at. DO set point can be configured in either mg/L or %Sat at the. Configure

at PID mode menu.

Control Up/Down

Configure the PID/PDW control system to either control up (Falling, to create a

control action to reduce down the system water parameter value) or control down

(Rising, to create a control action to increase up the system water parameter value).

A PID/PDW control can be used only to control the system by either driving the

system value up or down. A PID control cannot be used to drive the system value

both up and down.

PID/PWM Control Actions

Interval, Gain, Reset Interval

Configuration of three control actions allows for greater control and stablity of

a particular environment. The control actions are Gain (page 140), Reset/Inteval

(page 140) and Interval (page 140). These three controls actions are closely inter-

related in terms of how the PID/PWM algothrium works. The objective is to tune

and configure these control actions in order that the corrective action (output con-

trol on time) performed by the 5200A results in system stability. That is, the system

will hold the set point without oscillating wildly (overshooting or undershooting

by significant amounts) over and under the set point. A large amount of ocillation

could cause irreparable damage to the system by dosing too large an amount, or too

small an amount, of a control dosing additive to the system stream.

Configuring the 5200A