Measuring the manifold pressure, Adjusting the manifold pressure, Removing the manometer/pressure gauge – Reznor R8HE Unit Installation Manual User Manual

Page 20: Verifying over-temperature limit control operation, The manifold section, Conversion to lp/propane (sea level and, Figure

20

unit data label. To determine the firing rate, follow the

steps below:

1. Obtain the gas heating value (HHV) from the gas supplier.

2. Shut off all other gas fired appliances.

3. Start the unit in LOW heating mode and allow it to run

for at least 3 minutes.

4. Measure the time (in seconds) required for the gas

meter to complete one revolution.

5. Convert the time per revolution to cubic feet of gas per

.

6.Multiply the gas flow rate in cubic feet per hour by the

heating value of the gas in Btu per cubic foot to obtain

the firing rate in Btu per hour. See

.

EXAMPLE

(INPUT --> HIGH = 100,000 / LOW = 65,000)

• Time for 1 revolution of a gas meter with a 1 cubic foot dial

= 58 seconds.

, read 62 cubic feet gas per hour.

• Local heating value of the gas (obtained from gas supplier)

= 1,040 Btu per cubic foot.

• Low Input rate = 1,040 x 62 = 64,480 Btuh = PASS

7. Record your findings and move unit operation to HIGH

heating mode and Repeat Steps 3-6.

8. Adjust the manifold pressure if necessary by following

the steps in the Measuring & Adusting the Manifold

sections. For additional information about elevations

above 2,000 feet, see High Altitude Conversion section

(

).

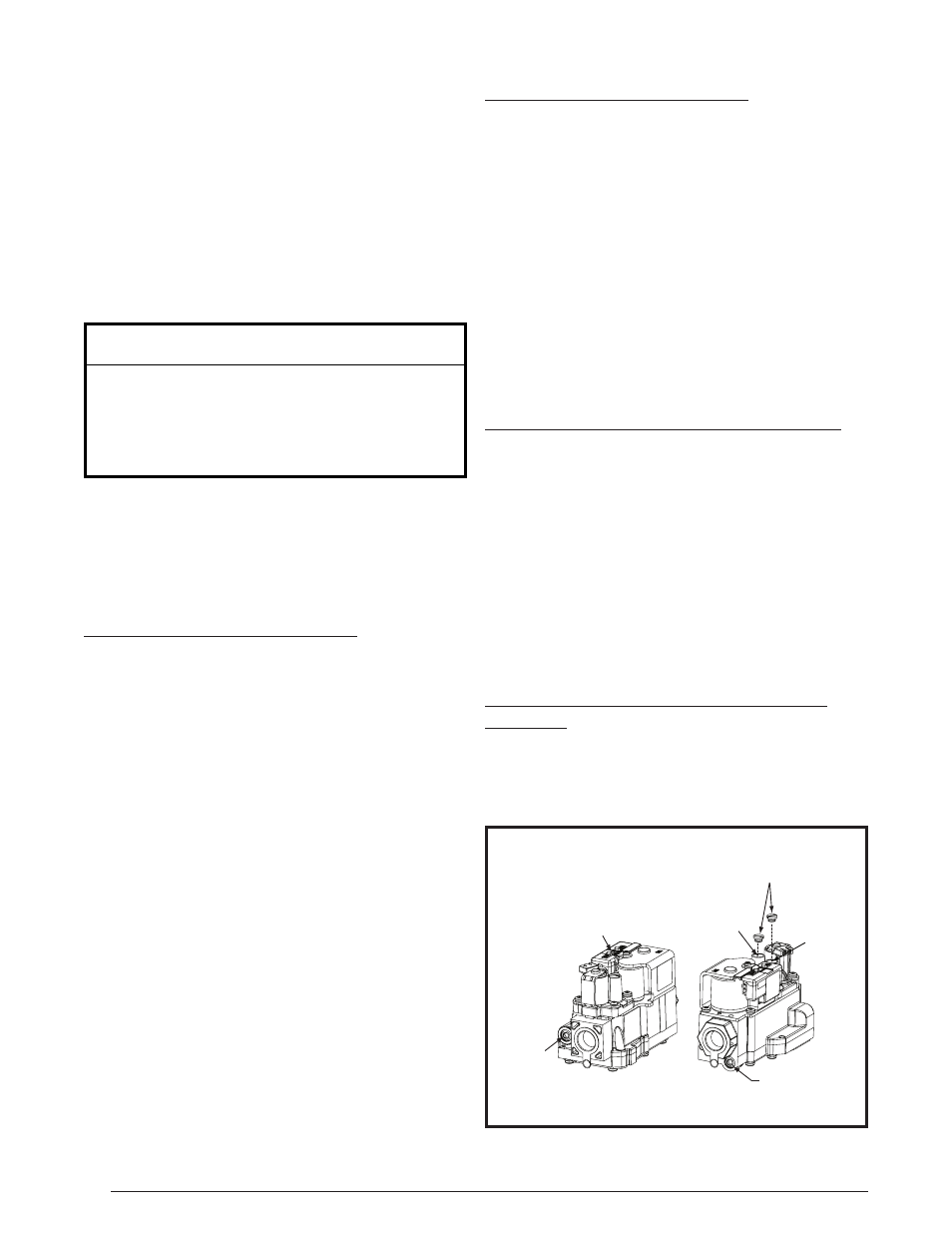

Measuring the Manifold Pressure

The manifold pressure must be measured for both LOW

and HIGH fire by installing a pressure gauge (Manometer,

Magnehelic Meter, etc.) to the outlet end of the gas valve

as follows:

1. Turn off all electrical power to the appliance.

2. Shut OFF the gas supply at the manual shutoff valve

located outside of the appliance.

3. Using a 3/16” Allen wrench, remove the manifold

pressure tap plug located on the outlet side of the gas

valve (

).

4. Install an 1/8” NPT pipe thread fitting, that is compatible

with a Manometer or similar pressure gauge.

5. Connect the Manometer or pressure gauge to the

manifold pressure tap.

6. Set the room thermostat 1 degree above room

temperature To start the furnace on LOW fire.

7. Allow the furnace to operate for 3 minutes and then

check the manifold pressure. Compare the measured

value with the value shown in

for

Natural Gas and

for LP/Propane

gas. If the manifold pressure is not set to the appropriate

pressure, then it must be adjusted.

8. Record your findings and move unit operation to HIGH

heating mode and Repeat Steps 3-6.

Adjusting the Manifold Pressure

NOTE: If adjustment must be made to either LOW or

HIGH fire settings perform the following steps:

1. Remove the cap screw from the top of the gas valve

regulator (

).

2. Using a screwdriver or Allen wrench (where appropriate),

slowly turn the adjustment screw till the appropriate

manifold pressure listed in

, or the

LOW and/or HIGH firing rate for your specific gas HHV

is achieved.

NOTE: Turning the screw clockwise increases the

pressure, turning the screw counter-clockwise

decreases the pressure. To prevent the screw from

backing all the way out from the valve, turn the screw

slowly.

3. Replace and tighten the cap screw or the plastic cap

over the adjustment screw.

Removing the Manometer/Pressure Gauge

After the LOW and HIGH manifold pressures are properly

adjusted, the Manometer or pressure gauge must be

removed from the gas valve.

1. Turn the thermostat to its lowest setting.

2. Turn OFF the main gas supply to the unit at the manual

shut-off valve, which is located outside of the unit.

3. Turn OFF all of the electrical power supplies to the unit.

4. Remove the pressure gauge adapter from the gas valve

and replace it with the 1/8” NPT manifold pressure plug

that had been removed earlier.

NOTE: Make sure the

plug is tight and not cross-threaded.

5. Turn ON the electrical power to the unit.

6. Turn ON the main gas supply to the unit at the manual

shut-off valve.

Verifying Over-Temperature Limit Control

Operation

1. Verify the louvered control access panel is in place and

that there is power to the unit.

2. Block the return airflow to the unit by installing a close-

off plate in place of or upstream of the filter.

Inlet

Pressure

Tap

Manifold

pressure

Tap

2-STAGE GAS VALVE

Model VR9205Q1127

ON / OFF

Switch

High Input

Adjusting

Screw

Lo Input

Adjusting

Screw

Cap

Screws

Figure 7. Regulator Capscrew & Tap Locations