High altitude conversion - natural gas, Lp / propane gas conversion, Figure 6 – Reznor R8HE Unit Installation Manual User Manual

Page 16: Hookup is shown in, Warning

16

applied on each joint or union using a small paintbrush.

If any bubbling is observed, the connection is not sealed

adequately and must be retightened. Repeat the tightening

and soap check process until bubbling ceases.

• If pressure testing the gas supply lines at pressures

greater than 1/2 psig (14 inches WC), the unit must

be disconnected from the gas supply piping system

to prevent damage to the gas valve.

• If the test pressure is less than or equal to 1/2 psig

(14 inches WC), the unit must be isolated from the

gas supply line by closing the manual shut-off valve.

High Altitude Conversion - Natural Gas

Conversion of this unit must be performed by qualified

service personnel, using only approved parts. All

installations must be made in accordance with the National

Fuel Gas Code and/or local jurisdiction codes.

WARNING:

The reduction of input rating necessary for high

altitude installation may only be accomplished

with factory supplied orifices. Do not attempt to

drill out orifices in the field. Improperly drilled

orifices may cause fire, explosion, carbon

monoxide poisoning, personal injury or death.

High altitude conversion can be field performed by a simple

adjustment of manifold pressure or a change of the orifices

(if necessary) as described in the Measuring & Adusting

the Manifold section (

). The changes required

depend on the installation altitude and the heating value

of the gas (based on sea level) which can be obtained

from your local gas utility. The heating value of gas at

high altitude is always lower than the sea level heating

value. Natural Gas heating values listed in

are based on sea level values.

All factory shipped furnaces are ready to operate using

Natural Gas between zero and 2,000 ft. above sea level.

For altitudes between 2,000 and 10,000 feet above sea

level, the unit can be converted by adjusting the unit’s

manifold pressure and/or changing the orifices. See

for the correct manifold pressure settings.

NOTE: If installing this unit above 2,000 feet, the input rate

must be reduced 4% per 1,000 feet of altitude (Example:

12% at 3,000 feet, 16% at 4,000 feet, etc). Deration is

necessary to compensate for low atmospheric pressure

at high altitudes.

LP / Propane Gas Conversion

WARNING:

This unit was equipped at the factory for use

with natural gas only. A special kit, supplied by

the manufacturer, is required to convert the unit

to operate on LP/propane gas. Failure to use the

proper conversion kit can cause fire, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

Conversion of this equipment to LP/Propane gas must

be made by qualified service personnel, using approved

factory parts. Conversion to LP can be accomplished by

replacing the natural gas orifices with the appropriate LP/

Propane orifices and then adjusting the manifold pressure

(

). Conversion to LP/Propane (sea level and

high altitude) is detailed in the installation instructions

provided with the conversion kit.

Please follow the

instructions provided in each kit. Approved conversion

kits are listed below:

• The United States LP/Propane Gas Sea Level and High

Altitude Conversion Kit (P/N 922311) is for LP/propane

conversion in the United States at altitudes between

zero and 10,000 ft. above sea level.

• The Canadian LP/Propane Gas Sea Level and High

Altitude Conversion Kit (P/N 922312) is for LP/propane

conversions in Canada at altitudes between zero and

4,500 ft. above sea level.

For installations between zero and 4,999 ft. above sea

level, a #55 drill size orifice should be used. Installations

5,000 ft. above sea level require a # 56 drill size orifice.

lists the correct orifice sizes and

manifold pressures for operation at different altitudes.

After changing the orifices, it is required that you measure

the gas input rate by clocking the gas meter and using

the local gas heating value. See Verifying the Firing Rate

of the Appliance section on

.

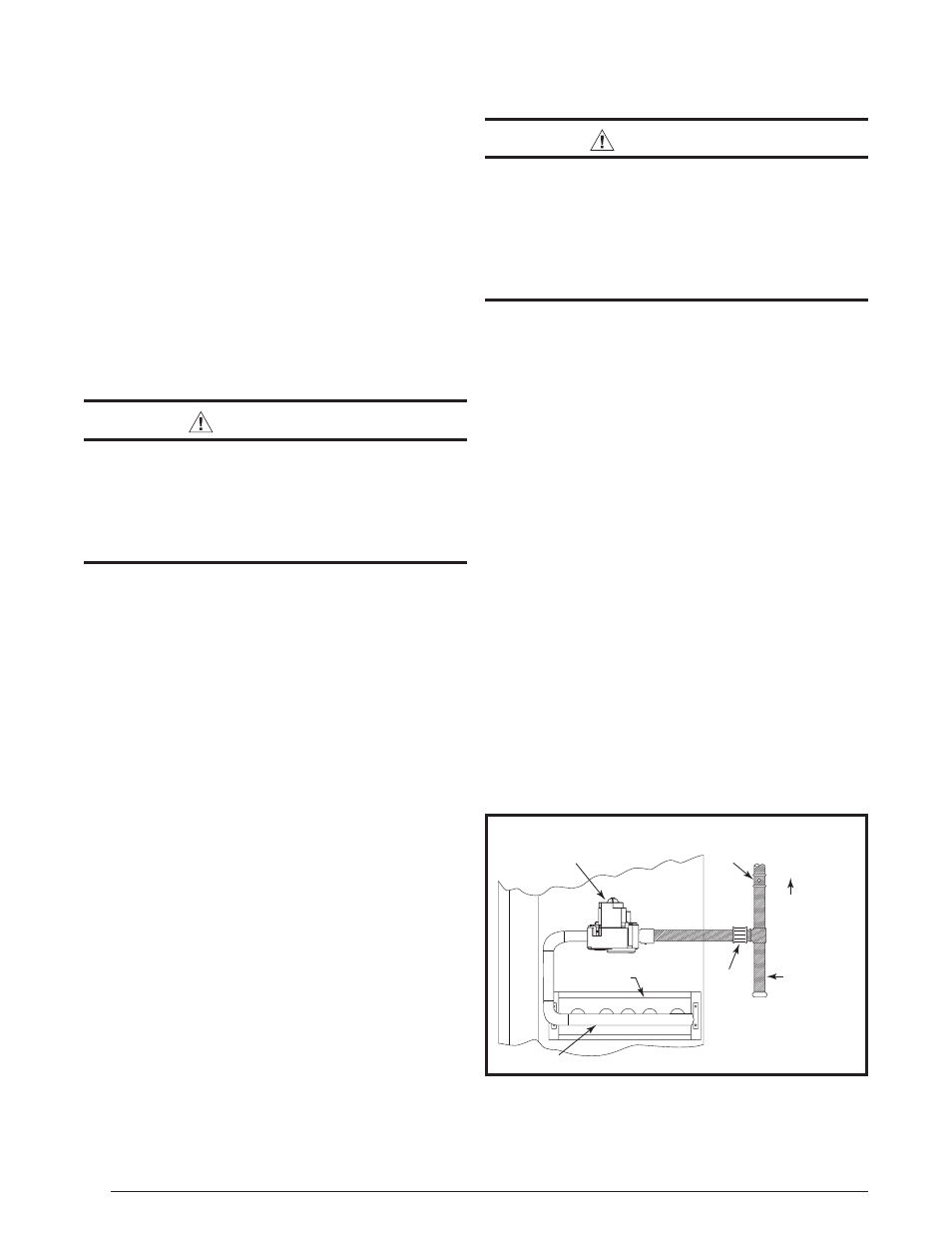

Ground

Joint

Union

Dripleg

Shut-Off Valve

with 1/8 NPT

plugged tap

Burner

Assembly

Manifold

Some utilities

require Shut-Off

Valve to be

4 to 5 feet

above floor

Automatic Gas Valve

(with manual shut-off)

Figure 6. Typical Gas Hookup - Right Side Entry