0 mechanical, 1 gas piping and pressures, 0 mounting (cont'd) – Reznor RPB Unit Installation Manual User Manual

Page 8: 3 mounting base and methods (cont'd), 3 mounting on a roof curb (cont'd)

Form I-RPB, P/N 131782 R11, Page 8

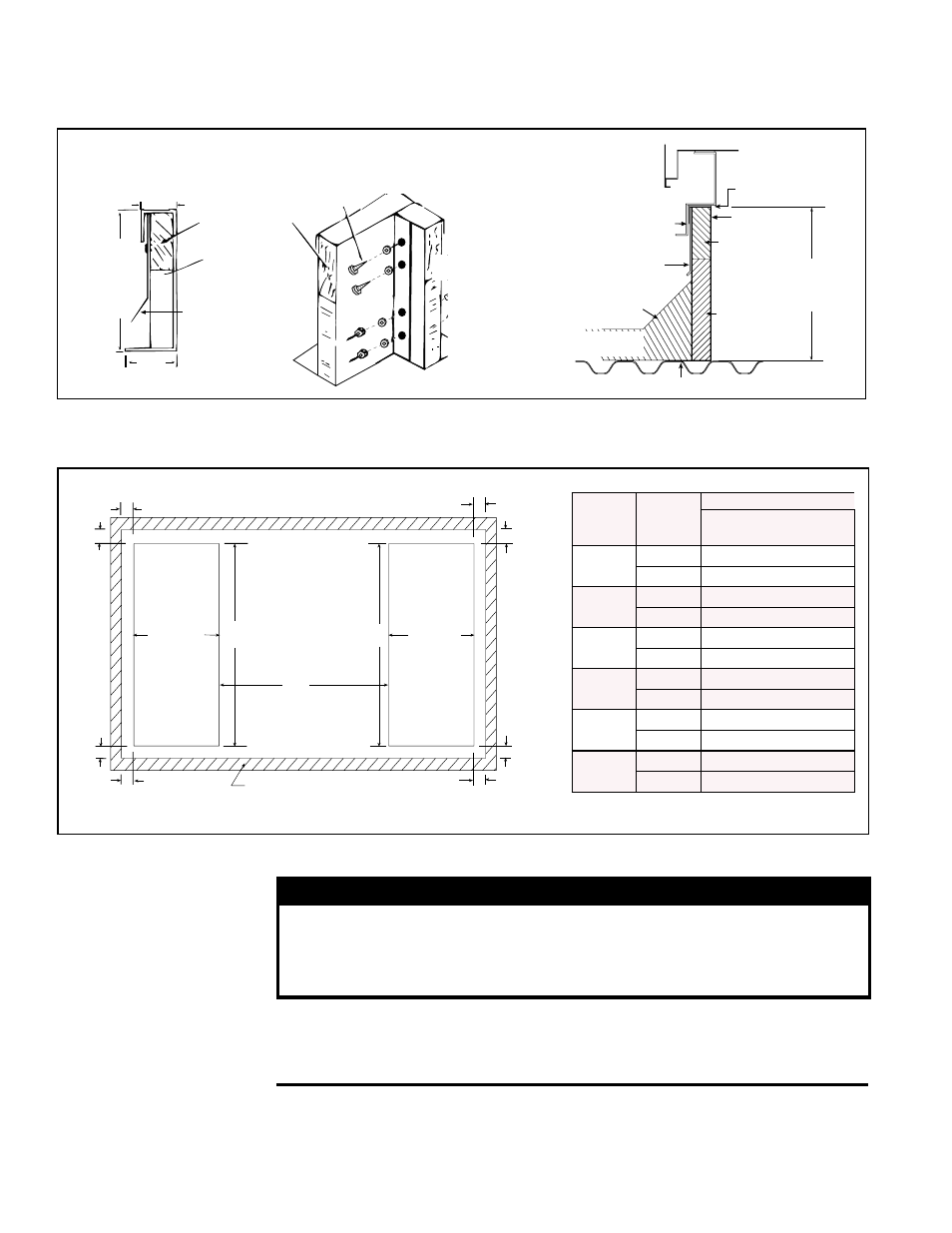

Bottom Duct Connections - The blower section and optional downturn plenum have duct flanges for connection to

return air and supply air ducts. Duct opening sizes and curb spacing shown in

FIGURE 4 is for currently manufactured

curbs that are available from the system manufacturer.

FIGURE 4 - Duct Opening Dimensions in Relation to Roof Curb Option - inches (mm)

1-5/8

(41)

1-5/8

(41)

1-5/8 (41)

1-5/8 (41)

1-5/8 (41)

1-5/8 (41)

19-1/2

(495)

19-1/2

(495)

H

H

G

Return

Duct

Supply

Duct

Roof Curb

1-5/8

(41)

1-5/8

(41)

•

1-5/8" (41mm) is the measurement from duct opening to inside edge of roof curb.

• Duct openings should be 1" larger than the duct size for installation clearance.

5.0 Mounting

(cont'd)

5.3 Mounting Base and Methods (cont'd)

5.3.3 Mounting on a Roof Curb (cont'd)

Sizes

H

G

With Downturn Plenum,

Option AQ5 or AQ8

125

17-3/8"

38-5/8"

441mm

981mm

150, 175

22-7/8

38-5/8

581mm

981mm

200, 225

28-3/8

38-5/8

721mm

981mm

250, 300

36-5/8

38-5/8

930mm

981mm

350

42-1/8

38-5/8

1070mm

981mm

400

47-5/8

38-5/8

1210mm

981mm

6.0 Mechanical

WARNING

This appliance is equipped for a maximum gas supply pressure

of 1/2 psi, 3.4 kPa, or 14 inches water column. Supply pressure

higher than 1/2 psi requires installation of an additional service

regulator external to the unit.

PRESSURE TESTING SUPPLY PIPING

Test Pressures Above 1/2 PSI: Disconnect the heater and manual valve from the

gas supply line which is to be tested. Cap or plug the supply line.

Test Pressures Below 1/2 PSI: Before testing, close the manual valve on the heater.

6.1 Gas Piping and Pressures

Roof Curb Assembly and Installation Instructions (cont'd)

All piping must be in accordance with requirements outlined in the National Fuel Gas

Code NFPA54/ANSI Z223.1 (latest edition) or CSA-B149.1 (latest edition) Natural Gas

and Propane Installation Code. Gas supply piping installation should conform with

good practice and with local codes.

16 (406mm)

1-7/8(48mm)

4

(102mm)

2 x 6 Wood Nailer

1-1/2 x 3 lb

Fiberglass

Flashed by the

installer (flashing must

be under lip of curb)

Lag Screw

Cap

Screws

Curb Cap

Counter Flashing

(by installer)

Cant Strip

(by installer)

MUST be sealed

between curb cap

and roof curb

2 x 6

Wood

Nailer

Insulation

16

(406 mm)

Curb Height

Cabinet

Curb Cap Skirt

Weld, bolt, or lag screw curb to deck structure.

Roof Curb

Roofing Felts

(by others)

Corner Detail

Curb Section

Typical

Curb Detail

FIGURE 3B - Roof Curb Assembly