2 pilot and ignition systems, Figure 35 - ignition controller – Reznor RPB Unit Installation Manual User Manual

Page 33

Form I-RPB, P/N 131782 R12, Page 33

8.2 Pilot and

Ignition

Systems

Flash Carryover

FIGURE 34 - Burner

Rack with Spark Pilot

Main

Burner

Spark Pilot

The horizontal pilot is located in the control end of the burner rack and is accessible

after the control compartment panel has been removed. All pilots are target type with

lint-free feature. Pilot gas pressure should be the same as supply line pressure. (See

Paragraph 6.1.) If required, adjust the pilot flame length to approximately 1-1/4" with

pilot adjustment screw in control valve body.

Intermittent Spark Ignition Safety Pilot Systems - There are two types of intermit-

tent spark pilots -- one type shuts off the pilot gas flow between the cycles and the

other not only shuts off the pilot gas flow between cycles but also has a lockout device

that stops the gas flow to the pilot if the pilot fails to light in 120 seconds. This lockout

feature has a 1-hour retry or requires manual reset by interruption of the thermostat

circuit. Propane units installed in Canada require the spark ignition system with the

lockout device. Refer to the wiring diagram supplied with the heater for pilot system

identification and wiring. Spark pilot without lockout is designated as Option AH2; with

lockout is Option AH3.

CAUTION: Due to high voltage on pilot spark wire and pilot elec-

trode, do not touch when energized. See Hazard Levels, page 2.

Service NOTE: If replacing an

earlier model of ignition controller,

order replacement kit

P/N 257472

for a unit with recycling gas control

Option AH2 or

P/N 257473 for

Option AH3 gas control with lock-

out. (Option codes are listed on the

unit wiring diagram.)

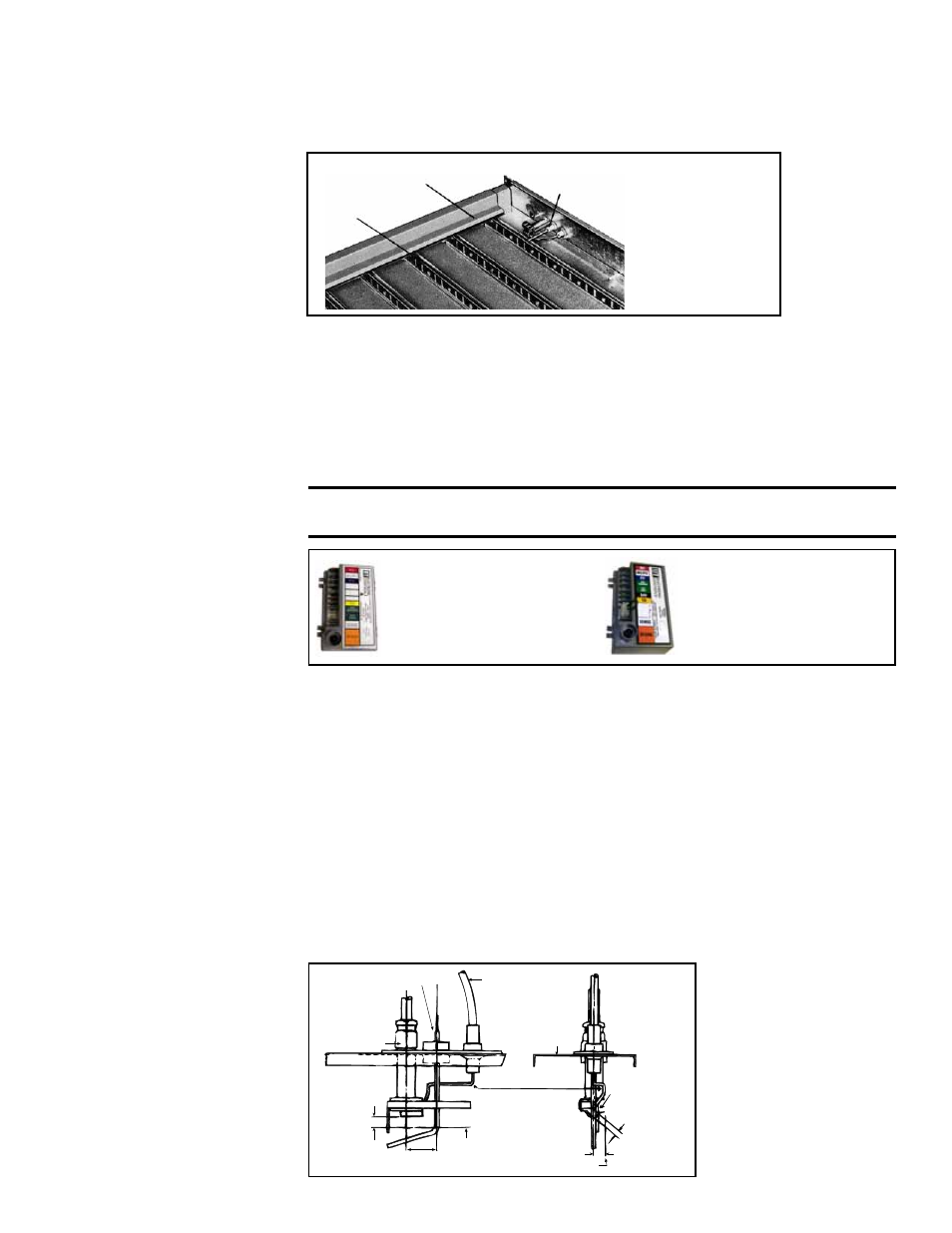

Recycling Ignition

Controller, UTEC 1003-638A,

P/N 257009, for Option AH2

Gas Control

Ignition Controller with

Lockout, UTEC 1003-514,

P/N 257010, for Option AH3

Gas Control

FIGURE 35 - Ignition

Controller

Ignition Controller - As part of the intermittent safety pilot systems, the ignition con-

troller provides the high voltage spark to ignite the pilot gas and also acts as the flame

safety device. After ignition of the pilot gas, the ignition controller electronically senses

the pilot flame. A low voltage DC electrical signal is imposed on the separate metal

probe in the pilot assembly. The metal probe is electrically insulated from ground. The

pilot flame acts as a conduction path to ground completing the DC circuit and proving

pilot flame.

Proper operation of the electronic spark ignition system requires a

minimum flame signal of .2 microamps as measured by a microampmeter. With

pilot flame proven, the ignition controller energizes the main gas valve.

Flame Sensing Probe

Pilot

Orifice

Centerline of

first burner

High Tension

Lead

Burner

Rack

Front

Spark Electrode

Spark Gap

7/64 (2.78mm)

TOP VIEW OF BURNER

TOP

VIEW

SIDE

VIEW OF

PILOT

1/4± 1/32

(6.38mm±.79)

23/32

(18.25mm)

7/16± 1/16

(11mm±1.6)

FIGURE 36 - Maintain

spark gap of 7/64"

If no spark occurs, check the following:

a) Voltage between Terminals TH and 7 on the ignition controller should be at least

20 volts and no higher than 32 volts. Refer to Troubleshooting (Paragraph 10.3) if

no voltage is observed.

b) Short to ground in the high tension lead and/or ceramic insulator.

c) Pilot spark gap should be approximately 7/64".