Reznor RPB Unit Installation Manual User Manual

Page 15

Form I-RPB, P/N 131782 R12, Page 15

Electric Box

Span

Adjust

Screw

Mounting Plate

Pressure Taps

Low

High

Pressure

Adjust Screw

Increasing

Decreasing

Linkage to

Diaphragm

Low

Common

High

Span Adjustment

Span of

floating

contact

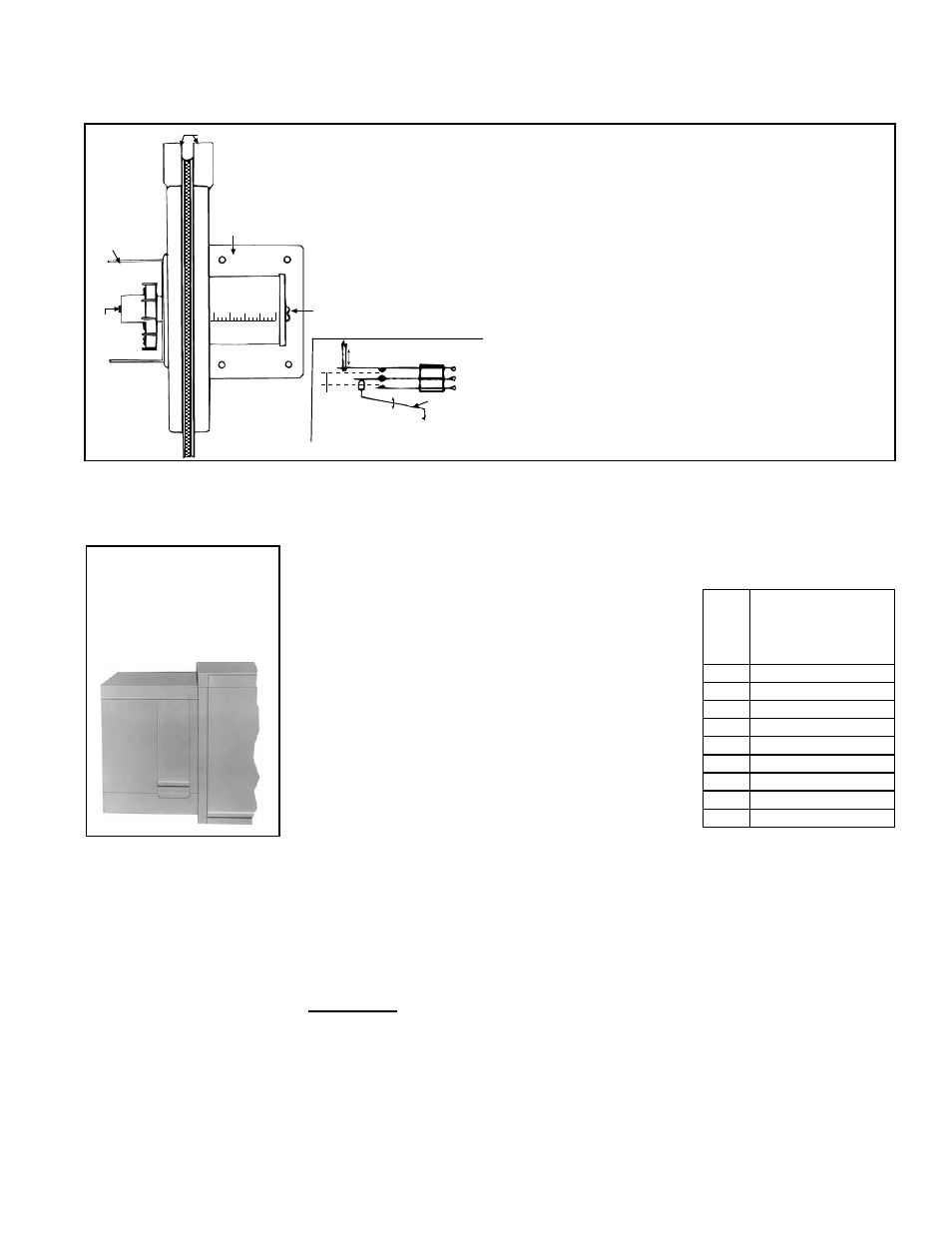

Switching action in the pressure null switch

FIGURE 13 - Pressure Null Switch (used with Inlet Air Option AR23)

IMPORTANT: To eliminate shipping damage to

the switch contacts, the manufacturer reduced

the span adjustment to zero before shipping.

The span should be adjusted prior to using

the switch. (If the switch has been installed,

disconnect the vent tube so that the null switch

is in a neutral position.) Remove the electrical

box cover and while observing the contacts, turn

the span adjustment screw slowly in a clockwise

direction. Continue turning the adjustment screw

until you are able to see gaps between the

common and both the low and high contacts. A

minimum gap provides the greatest sensitivity.

The wider the gap the lower the sensitivity.

Building pressure is set by turning the adjustment screw. The "Low" actuation point

is set by adjusting the span of the null by turning the span adjustment screw. The

span range is .01 to .03" w.c.

5. See the wiring diagram included with the furnace to make electrical connections.

6.3.4 Evaporative

Cooling Module,

Option AS 3, 4, 5, 8

General - Evaporative cooling provides excellent comfort cooling at low initial equip-

ment and installation costs and low operating and maintenance costs. Direct evapo-

rative cooling works solely on the principle that water in direct contact with a moving

airstream will eventually evaporate if the droplets have long enough exposure. This

evaporative cooling module uses wetted rigid cellulose or rigid glass fiber media to

retain water in order to allow time for evaporation.

FIGURE 14 - Optional

Evaporative Cooling

Module is factory-

installed on the

blower cabinet

The optional evaporative cooling module is equipped

with high efficiency pad media of 12" rigid cellulose

(Option AS4) or 12" rigid glass fiber (Option AS8). 12"

media provides 90% efficiency. Efficiency values are

stated at maximum allowable CFM without the addi-

tion of a moisture elimination pad with an inlet dry bulb

temperature of 95°F and inlet wet bulb temperature of

65°F. The evaporative cooling efficiency is a function

of inlet temperature and of face velocity through the

media. The stated cooling efficiency will rise with the

decrease of CFM and the increase of inlet tempera-

ture. Moisture elimination pads (Option ASA1) may be

used on all units but are required on high CFM units as

listed in the table.

The standard water controls for the evaporative cooling module include the float valve,

the float switch, and pump assembly illustrated in the following paragraphs. If the cool-

ing module has an optional AquaSaver

metering water system, it will not have these

controls but will have a solenoid valve with a timer assembly for controlling water flow.

RPB

Size

Moisture Elimina-

tion Pad Required

on Evaporative

Cooling Module

125

2601 - 3800 CFM

150

3201 - 4700 CFM

175

3201 - 5000 CFM

200

3701 - 5100 CFM

225

3701 - 5150 CFM

250

4501 - 5800 CFM

300

4501 - 6300 CFM

350

5101 - 6800 CFM

400

5601 - 7100 CFM

Supply and Drain Water

Connections

Installation Instructions

- Evaporative Cooling

Module

The evaporative cooling module is factory assembled, installed and wired. No addi-

tional roof mounting is necessary. Read the following to field connect the water supply

and make necessary checks and adjustments before operating the cooling module.

Float Valve (FIGURE 15)

In a module with pump and float controls, a float valve maintains the appropriate water

level in the reservoir.

Use a field-supplied 1/4" diameter tubing with a compression nut and tubing ferrule to

connect the fresh water supply to the inlet of the float valve. See

FIGURE 15. Place nut

and ferrule over tubing and insert tubing into the float valve stem. Tighten nut securely.

An optional automatic fill and drain kit (Option CT) is available that will automatically

release supply water to the cooling module when a call for cooling is made and drain

all water from the reservoir when the cooling switch is deactivated or a cooling ther-