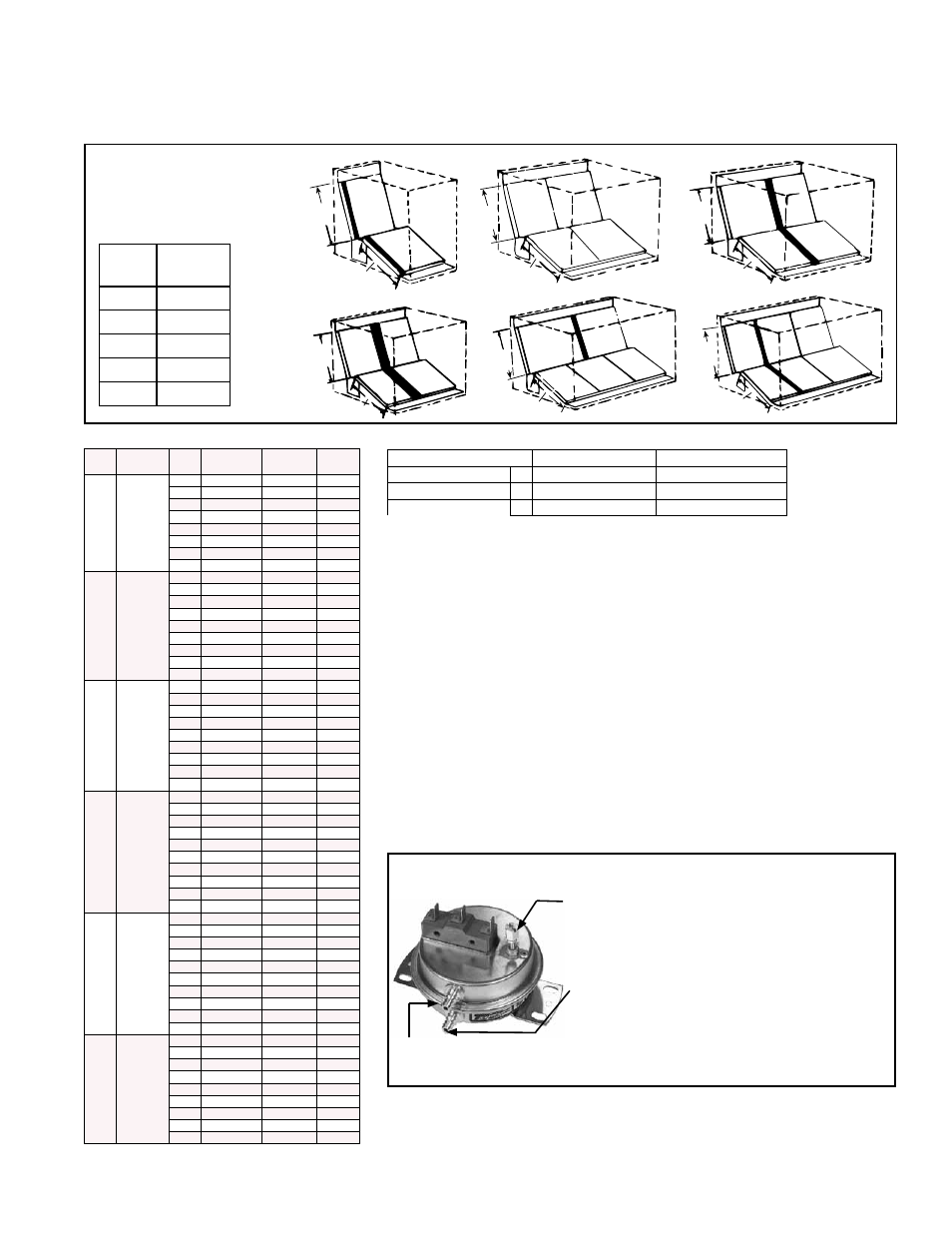

2 filter rack and filters, option aw, Figure 10 - filter arrangements, Average efficiency and arrestance by filter type – Reznor RPB Unit Installation Manual User Manual

Page 13: Filter pressure drops (" w.c.), Optional dirty filter switch

Form I-RPB, P/N 131782 R12, Page 13

6.3.2 Filter Rack and

Filters, Option AW

Filter rack and filters are factory installed optional equipment. Refer to

FIGURE 10, for

filter arrangements.

Tested in accordance with ASHRAE 52-76 Test Standard, the filters provided have the

specifications shown in the table below.

Size, quantity, and pressure drops of filters for outdoor models shown below.

FIGURE 10 - Filter

Arrangements

Shaded areas are filter

blockoff plates.

Filter

Code

Filter

Size

A

16 x 20

B

20 x 20

C

16 x 25

D

20 x 25

E

25 x 25

D

E

Size 125

25 (635m

m)

20

(508mm)

Sizes 150-175

A

A

C

C

25 (635m

m)

20

(508mm)

Sizes 200-225

A

B

C

D

25 (635m

m)

20

(508mm)

Sizes 250-300

B

D

D

E

25 (635m

m)

20

(508mm)

20

(508mm)

A

B

C

D

25 (635m

m)

Size 350

D

D

D

C

C

Size 400

25 (635m

m)

20

(508mm)

B

D

Average Efficiency and Arrestance by Filter Type

Type of Filter

Average Efficiency Average Arrestance

Disposable

2"

Less than 20%

80%

Permanent

2"

Less than 20%

64% to 67%

Pleated Disposable 2"

30% to 35%

90% to 93%

Filter Pressure Drops (" w.c.)

RPB

Size

Qty & Size

of Filters

CFM Disposable Permanent Pleated

125

(1) 20x25;

(1) 25x25

575

0.00

0.01

0.01

1000

0.01

0.03

0.04

1500

0.02

0.06

0.08

2000

0.02

0.11

0.15

2500

0.03

0.17

0.23

3000

N/A

0.24

0.33

3500

N/A

0.34

0.45

4000

N/A

0.43

N/A

150,

175

(2) 16x20;

(2) 16x25

1175

0.01

0.03

0.03

1500

0.01

0.06

0.05

2000

0.02

0.08

0.09

2500

0.03

0.14

0.14

3000

0.04

0.20

0.23

3500

0.05

0.28

0.27

4000

0.07

0.36

0.36

4500

N/A

0.45

0.45

5000

N/A

0.54

0.56

200,

225

(1) 16x20;

(1) 16x25;

(1) 20x20;

(1) 20x25

1550

0.01

0.04

0.04

2000

0.01

0.07

0.07

2500

0.02

0.11

0.11

3000

0.03

0.16

0.16

3500

0.04

0.22

0.21

4000

0.05

0.28

0.27

4500

0.06

0.36

0.35

5000

N/A

0.44

0.43

5400

N/A

0.52

0.50

250,

300

(1) 20x20;

(3) 20x25

1950

0.02

0.05

0.05

2500

0.03

0.08

0.08

3000

0.04

0.12

0.11

3500

0.05

0.16

0.15

4000

0.07

0.21

0.20

4500

0.09

0.26

0.25

5000

0.11

0.32

0.31

5500

N/A

0.39

0.37

6000

N/A

0.46

0.44

6500

N/A

0.54

0.52

350

(2) 16x25;

(3) 20x25

2750

0.03

0.08

0.08

3500

0.04

0.13

0.13

4000

0.06

0.17

0.17

4500

0.07

0.21

0.22

5000

0.09

0.26

0.27

5500

0.10

0.32

0.33

6000

0.12

0.38

0.39

6500

N/A

0.44

0.46

7000

N/A

0.51

0.53

3100

0.04

0.08

0.08

400

(1) 16x20;

(1) 16x25;

(2) 20x20;

(2) 20x25

3500

0.06

0.11

0.11

4000

0.07

0.14

0.14

4500

0.09

0.18

0.18

5000

0.12

0.22

0.22

5500

0.14

0.27

0.27

6000

0.17

0.32

0.32

6500

0.20

0.38

0.37

7000

0.23

0.44

0.43

7400

N/A

0.49

0.48

Optional Dirty Filter Switch

The optional dirty filter pressure switch is used to provide warning to the

user by energizing an indicator light on an optional remote console. The

light indicates that the filters are in need of cleaning or changing. The

adjustable, single-pole/normally open differential switch closes when an

increase in pressure differential above the setpoint, is sensed across the

filter bank.

This switch is located in the furnace section. See page 28,

FIGURE 29

Item 17. After the unit is started, before continuous operation, the dirty filter

switch must be set.

Instructions for Setting Switch

With clean filters in place, blower doors closed, and blower in operation,

decrease the pressure setting by adjusting the setscrew on the switch

clockwise until the filter light is energized or the screw is bottomed out.

At that point, adjust the set screw three full turns counterclockwise or until

the screw is top-ended. At that setpoint the filter light will be activated at

approximately 50% filter blockage.

FIGURE 11 - Dirty Filter Switch

Setscrew (on front of switch)

must be manually adjusted

after the system is in operation.

Negative pressure connection is toward the "front or top"

of the switch (senses blower side of filters)

Positive pressure connection is

toward the "back or bottom" of the

switch (senses air inlet side of filters)