0 mechanical (cont'd), 3 unit inlet air (cont'd) – Reznor RPB Unit Installation Manual User Manual

Page 18

Form I-RPB, P/N 131782 R11, Page 18

6.3 Unit Inlet Air

(cont'd)

6.0 Mechanical

(cont'd)

A

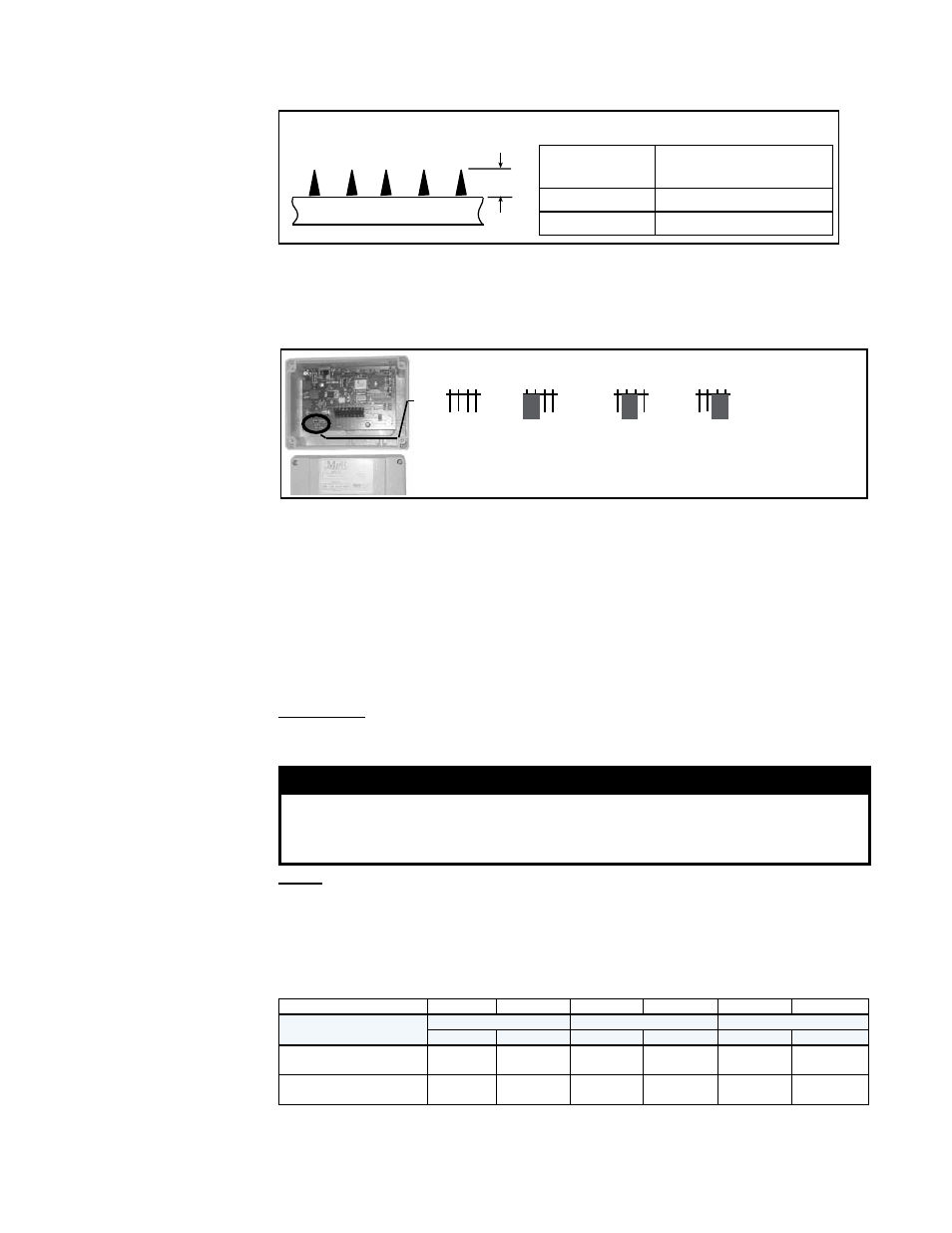

FIGURE 19A - Adjust Water Flow with the Ball Valve in FIGURE 18

Sprinkler Pipe

Pad

Height

A=Water Rise from

PVC Sprinkler Pipe

24" (610mm)

1/8" to 1/2" (3 to 13mm)

48" (1219mm) 1/4" to 1/2" (6 to 13mm)

FIGURE 19B -

AquaSaver

Microprocessor Control

in the Junction Box

J2

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

S

M

L

12-36

(305-914mm)

Media Height

37-48

(940-1219mm)

Media Height

49-72

(1245-1829mm)

Media Height

2) AquaSaver Timer Adjustment - At any given temperature, the media pads should

completely wet from top to bottom during the ON cycle. The microprocessor has three

preset timing settings based on media size. The appropriate setting is selected by

changing the position of the suitcase jumper at J2 on the microprocessor. Remove the

cover and check the setting (See

FIGURE 19B).

If the jumper is at the appropriate location for the media, replace the cover. If the

jumper needs to be moved, move it to the appropriate setting. The setting will go into

effect when the power is restored.

Check the "ON" timing; the media pads should be wet from top to bottom during the

ON cycle.

If the preset timing is not suitable for the application, follow the instructions supplied

with the microprocessor to change the calibration of the "On" and/or "Off" cycle.

NOTE: Prior to 2003 the AquaSaver timed cycle was controlled by a mechanical timer.

Turn the adjustment screw clockwise to increase the ON time or counterclockwise to

decrease the ON time. One complete turn will adjust the cycle by 12 to 14 seconds.

All Modules - Check the reservoir for any water leaks. The reservoir was water tested,

but if any small leaks are present, drain the reservoir and apply a waterproof silicone

sealer around corners and welds.

Reference:

Troubleshooting Guide

on page 20.

1) AquaSaver Water Flow Adjustment - Using the ball valve illustrated in FIGURE 18,

adjust the water flow depending on the pad height. See

FIGURE 19A.

6.3.4 Evaporative

Cooling Module,

Option AS 3, 4, 5, 8

(cont'd

)

Evaporative Cooling

Module Maintenance

Adjusting Water Flow Over Pads (cont'd)

WARNING

Disconnect all power to the unit before doing any maintenance.

Failure to do so can cause electrical shock, personal injury or

death.

Media - Over time, excessive amounts of mineral deposits may begin to build up on the

media. Annually, scale and dirt should be washed off the entering surface of the media.

Remove the pad retainers and screen (See Steps 1-3 and 6-8 of Media Replacement

Instructions). Clean the media using a garden hose, mild cleaner, and a

soft bristled

brush. When the media becomes too clogged with mineral deposits and dirt that it

cannot be cleaned, the pads should be replaced. The average pad life expectancy is

approximately three cooling seasons.

RPB Size

125

150, 175

200, 225

250, 300

350

400

12" Media Pads - dimen-

sions and (Qty)

(2) 24x12

(3) 24x12

(4) 24x12

(1) 24x2-3/8 (1) 24x7-7/8 (1) 24x1-3/8 (1) 24x9-5/8 (1) 24x2-7/8 (1) 24x8-5/8

Cellulose Fiber Media

Replacement P/N's & (Qty)

(2) 106021;

(1) 106022

(2) 106021;

(1) 106023

(3) 106021;

(1) 106024

(3) 106021;

(1) 106025

(4) 106021;

(1) 106026

(4) 106021;

(1) 106027

Glass Fiber Media

Replacement P/N's & (Qty)

(2) 106029;

(1) 106030

(2) 106029;

(1) 106031

(3) 106029;

(1) 106032

(3) 106029;

(1) 106033

(4) 106029;

(1) 106034

(4) 106029;

(1) 106035

Select the correct replacement part numbers and order replacement media pads from

your distributor. Follow the instructions that follow and remove and replace pads as

shown in

FIGURES 20 and 21.