3 troubleshooting, 0 maintenance and service (cont'd), 2 maintenance procedures (cont'd) – Reznor RPB Unit Installation Manual User Manual

Page 38: Troubleshooting the system, 4 clean the heat exchanger (cont'd)

Form I-RPB, P/N 131782 R11, Page 38

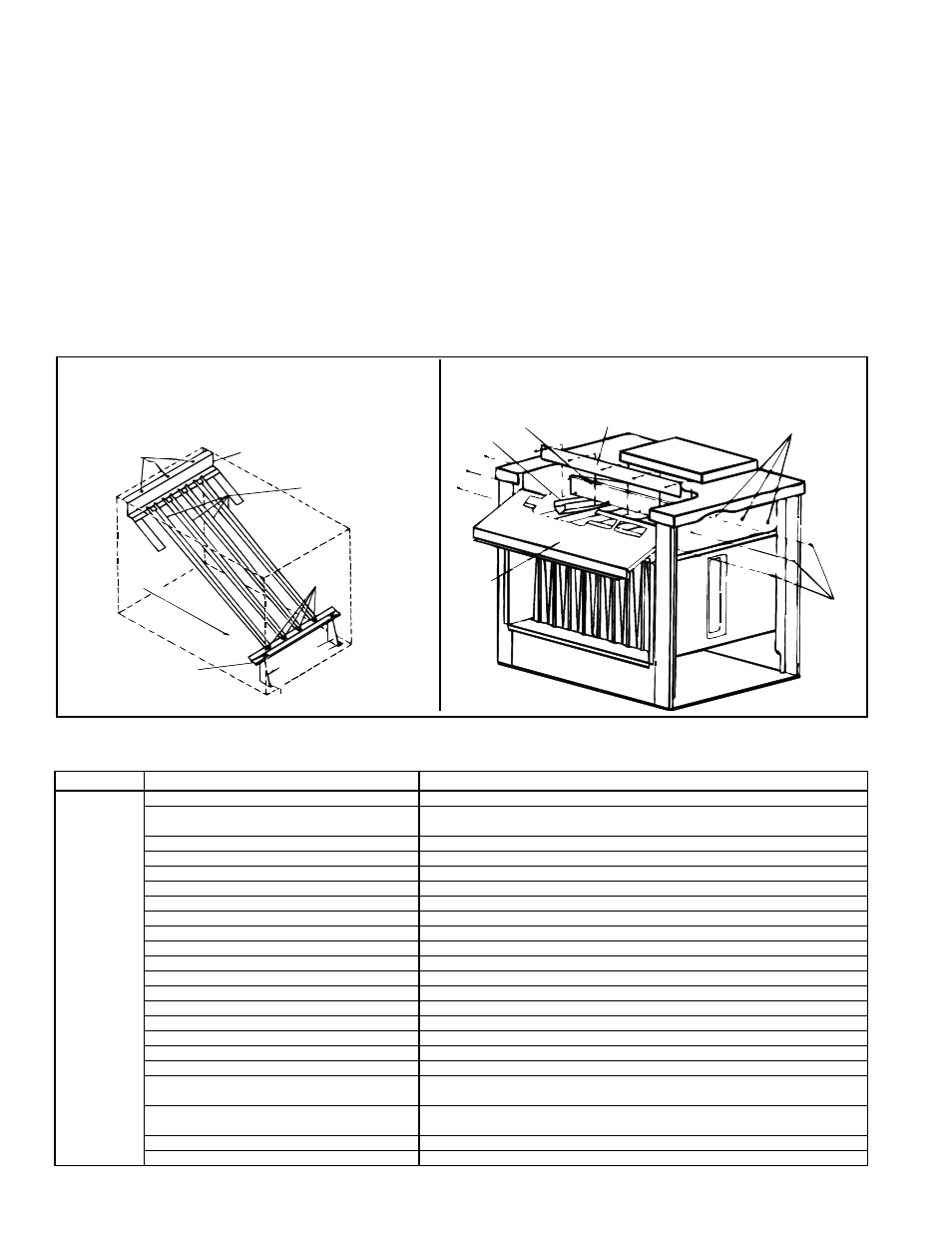

FIGURE 39 - Remove "V" Baffles to Clean Inner

Surface of Heat Exchanger Tubes

Loosen

Screws

Remove

Screws

Tube Baffle Holddown Plate

Rear Baffle

Front

Baffle

Tube

Baffle

Top Baffle

Support

Screws

B

Bottom

Baffle Support

Bracket

s

Air Discharge

Direction of

Airflow

Screw C

Right

Lef

t

Screws A

Screw C

Airflow

Baffles

FIGURE 38 - When cleaning outer heat

exchanger surface remove directional air

baffles. Remove Screws "A" and slide baffles

out. Clean and replace all baffles.

Troubleshooting the System

10.3 Troubleshooting

TROUBLE

PROBABLE CAUSE

REMEDY

Venter motor

will not start.

Pilot will not

light. (Venter

operating on

power-vented

models.)

1. No power to the furnace.

1. Turn on power, check supply fuses or circuit breaker.

2. No 24-volt power to venter relay.

2. Turn up thermostat, check control transformer output. Check for loose or improper

wire connections.

3. Venter relay defective.

3. Replace.

4. Defective motor or capacitor.

4. Replace defective part.

1. Manual valve not open.

1. Open manual valve.

2. Air in gas line.

2. Bleed gas line.

3. Dirt in pilot orifice.

3. Remove and clean with compressed air or solvent (do not ream).

4. Gas pressure too high or too low.

4. Adjust supply pressure. (See Paragraph 6.1).

5. Kinked pilot tubing.

5. Replace tubing.

6. Pilot valve does not open.

6. If 24 volt available at valve, replace valve.

7. No spark:

7.

a) Loose wire connections

a) Be certain all wires connections are solid.

b) Transformer failure.

b) Be certain 24 volts is available.

c) Incorrect spark gap.

c) Maintain spark gap at 7/64".

d) Spark cable shorted to ground.

d) Replace worn or grounded spark cable.

e) Spark electrode shorted to ground.

e) Replace pilot if ceramic spark electrode is cracked or grounded.

f) Drafts affecting pilot.

f) Make sure all panels are in place and tightly secured to prevent drafts at pilot.

g) Ignition control not grounded.

g) Make certain ignition control is grounded to furnace chassis.

h) Faulty ignition controller.

h) If 24 volt is available to ignition controller and all other causes have been

eliminated, replace controller.

8. Optional lockout device interrupting control circuit

by above causes.

8. Reset lockout by interrupting control at thermostat.

9. Faulty combustion air proving switch.

9. Replace combustion air proving switch.

10. Activated blocked vent switch (indoor system)

10. Correct venting problem. Reset switch.

10.2 Maintenance

Procedures

(cont'd)

10.0 Maintenance

and Service

(cont'd)

10.2.4 Clean the Heat Exchanger (cont'd)

NOTE: High efficiency

furnaces manufactured prior

to 3/95 have a "C" prefix in

their model designation.

All

furnaces manufactured

beginning 3/95 are designed

for high efficiency and

include the heat exchanger

"V" baffles.

Instructions to Remove Heat Exchanger "V" Baffles (FIGURES 38 & 39.)

1) Remove the ends of the flue gas collection box. On the control side of the

furnace, remove the venter assembly and the flue outlet duct to gain access to the

collection box end.

2)

Sizes 125-300 -- Remove one of the tube baffle retaining angles on each inside

wall of the collection box. Each tube baffle angle has one screw.

Size 400 -- Remove the inner baffle from the flue collection box. On the control

side, align the inner baffle with the slot in the collection box edge. Pull the inner

baffle until it clears the heat exchanger. Remove the screw at each end and slide

the flue diverter out of the furnace.

3) Pull the "V" baffles out of the heat exchanger.

Clean the inner surfaces of the heat exchanger from beneath using the brush to "scrub"

the tube walls to remove any accumulated dust, rust and/or soot. Clean the "V" tubes

and re-assemble the heat exchanger and the furnace.

Check the furnace for proper

operation.