0 controls (cont'd), 1 gas controls (cont'd) – Reznor RPB Unit Installation Manual User Manual

Page 30

Form I-RPB, P/N 131782 R11, Page 30

8.1.3. Optional 2-Stage Operation - Makeup Air Application

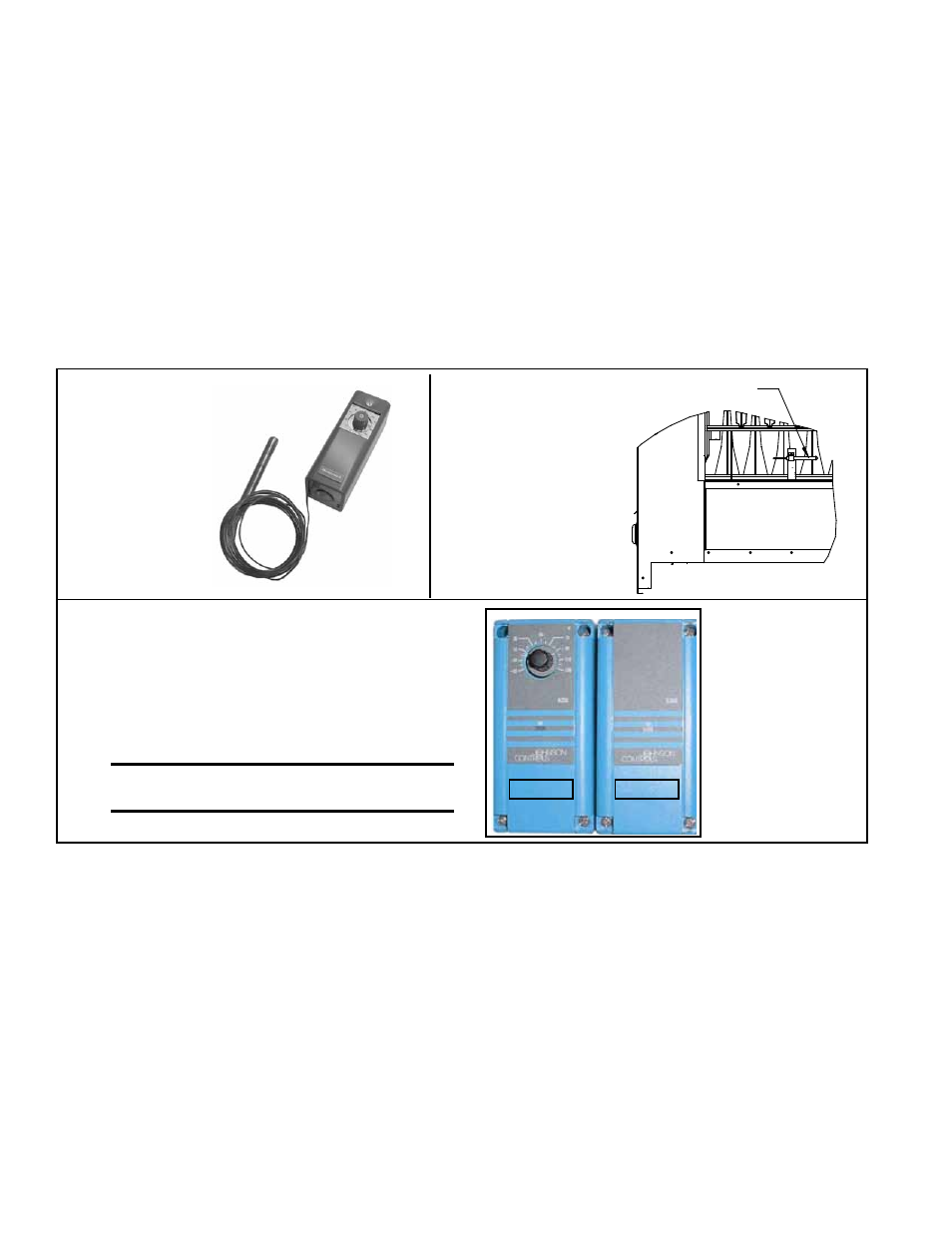

Optional Ductstat with Capillary Tubing (Option AG3) - The ductstat illustrated in

FIGURE 30A is used with Option AG3. The control is set to 70°F and has an adjust-

able range with a fixed differential of 3°F. Due to different CFM settings and outside air

temperatures, the average downstream outlet temperature may not match the ductstat

setting exactly. After the installation is complete, adjust the setpoint of the ductstat to

achieve the desired average outlet air temperature.

Optional Ductstat with Electronic Remote Setpoint Module (Option AG15) - The

sensing probe is field-wired to a remote temperature selector with a temperature

operating range to 130°F. The sensing probe and remote modules (

FIGURE 31) are

shipped separately for field installation. Follow the instructions in Paragraph 6.4.2 for

installing the sensor. Refer to the wiring diagram with the unit and the manufacturer's

instructions for wiring and installing the remote modules. Follow the wiring diagram

with the unit and the manufacturer's instructions for wiring and installation.

See

FIGURE 31. There will be one module for selecting temperature and one-stage

adder module.

8.1.4 Optional

Electronic Modulation

The type and capability of the electronic modulation system depends on the option

selected. Electronic modulation options are identified by a suffix to the Serial No.

printed on the heater rating plate. AG7 is identified as MV-1; AG8 is identified as MV-3;

AG9 is identified as MV-4; AG21 is identified as MV-A; AG39 is identified as MP-1; and

AG40 is identified as MP-2.

Installation NOTE: Sizes 350 and 400 with electronic modulation require a minimum

of 6" w.c. natural gas supply pressure.

8.0 Controls

(cont'd)

8.1 Gas Controls

(cont'd)

FIGURE 30B -

Ductstat Bulb

in Option AG3

(factory installed)

FIGURE 30A - Ductstat Control

in Option AG3

Factory

set at

70°F

Adjustable range

0-100°F with a fixed

differential of 3°F.

Ductstat Sensor Bulb

- Option AG3

FIGURE 31 - Remote Temperature Selector (A)

and Stage-Adder Module (B) In Gas Control

Options AG15

(A)

CAUTION: Be sure heat/cool selector

switch is set at "Heat" position.

(B)

Electronic Modulation

between 50% and 100%

Firing Rate

(Options

AG7, AG8, AG9)

Depending on the heat requirements as established by the thermistor sensor, the

burner modulates between 100% and 50% firing. The thermistor is a resistor that

is temperature sensitive in that as the surrounding temperature changes, the Ohms

resistance changes through the thermistor. This change is monitored by the solid state

control center (amplifier) which furnishes varying DC current to the modulating valve

to adjust the gas input.

Each modulating valve is basically a regulator with electrical means of raising and

lowering the discharge pressure. When no DC current is fed to this device, it functions

as a gas pressure regulator, supplying 3.5" w.c. pressure to the main operating valve.

Refer to the wiring diagram supplied with the furnace for proper wiring connections.